Roundness angle sorting and dividing plate

An angle subdivision and reticle technology, applied in measuring devices, instruments, optical devices, etc., can solve the problems of low precision of the blade angle and inability to measure the circular arc of the blade

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

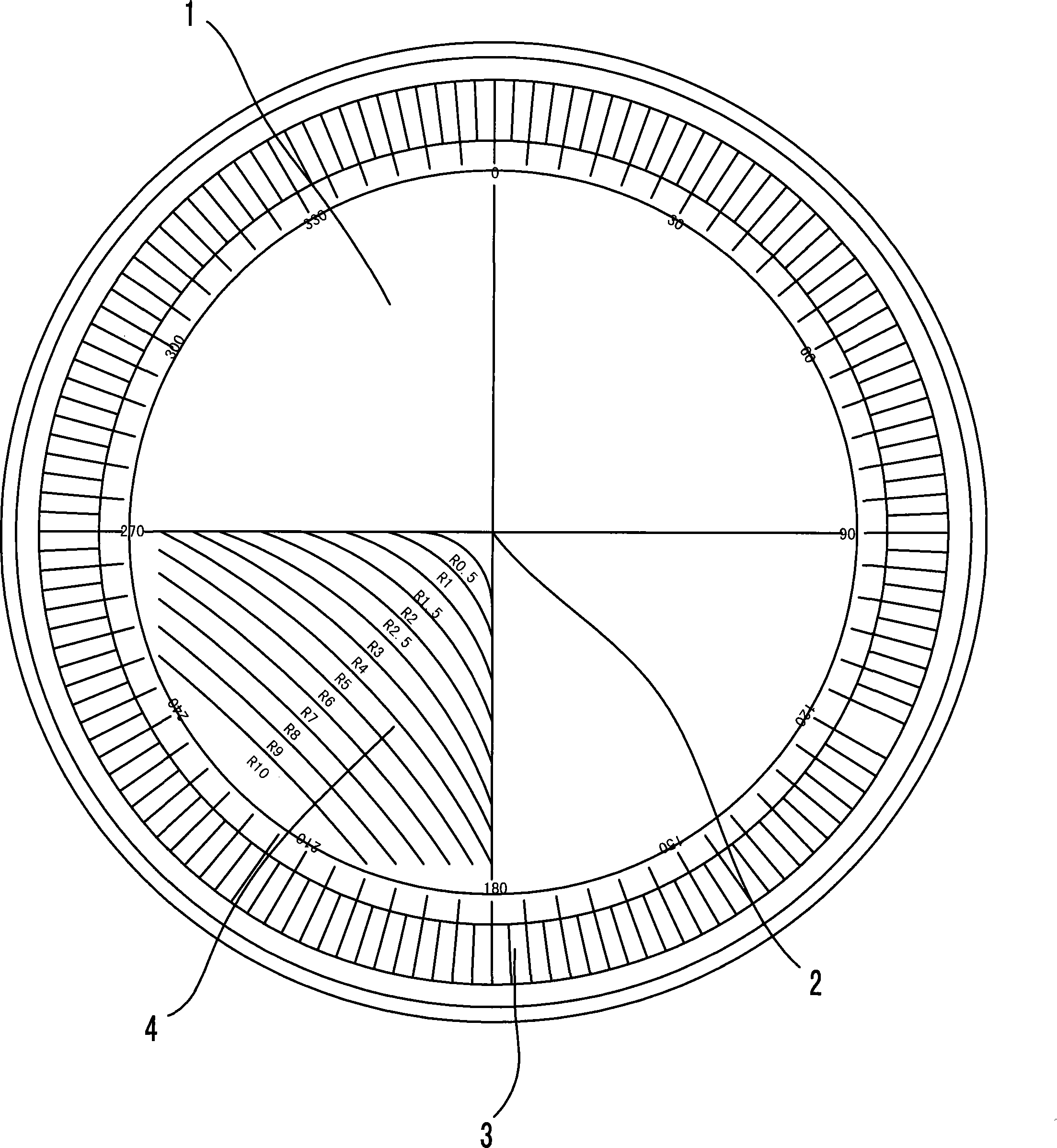

[0025] Such as figure 1 As shown, a roundness angle subdivision reticle includes a reticle body 1 and a cross line 2 engraved on the reticle body 1, and the reticle body 1 is also engraved with graduation lines and radians Graduation line, the graduation reticle is a set of graduation reticle 3 evenly distributed along the circumferential direction, the center of the graduation reticle coincides with the center of the cross line 2; The center of the line 2 is the center of the circle, and N graduation lines 3 are engraved within 360°, such as one graduation line 3 at intervals of 2°30′ within 360°, such as 0°, 2°30′, 5°0′ , 7°30′, ...... etc.

[0026] Described radian reticle is a group of radian reticle 4, and this radian reticle 4 is a group that is described outwardly from the center of cross line 2 in the third quadrant of reticle body 1 and the standard size series of cutter blade arc radius ( Such as R0.5, R1.0, R1.5, R2.0, R2.5, ... etc.) corresponding to the radian s...

Embodiment 2

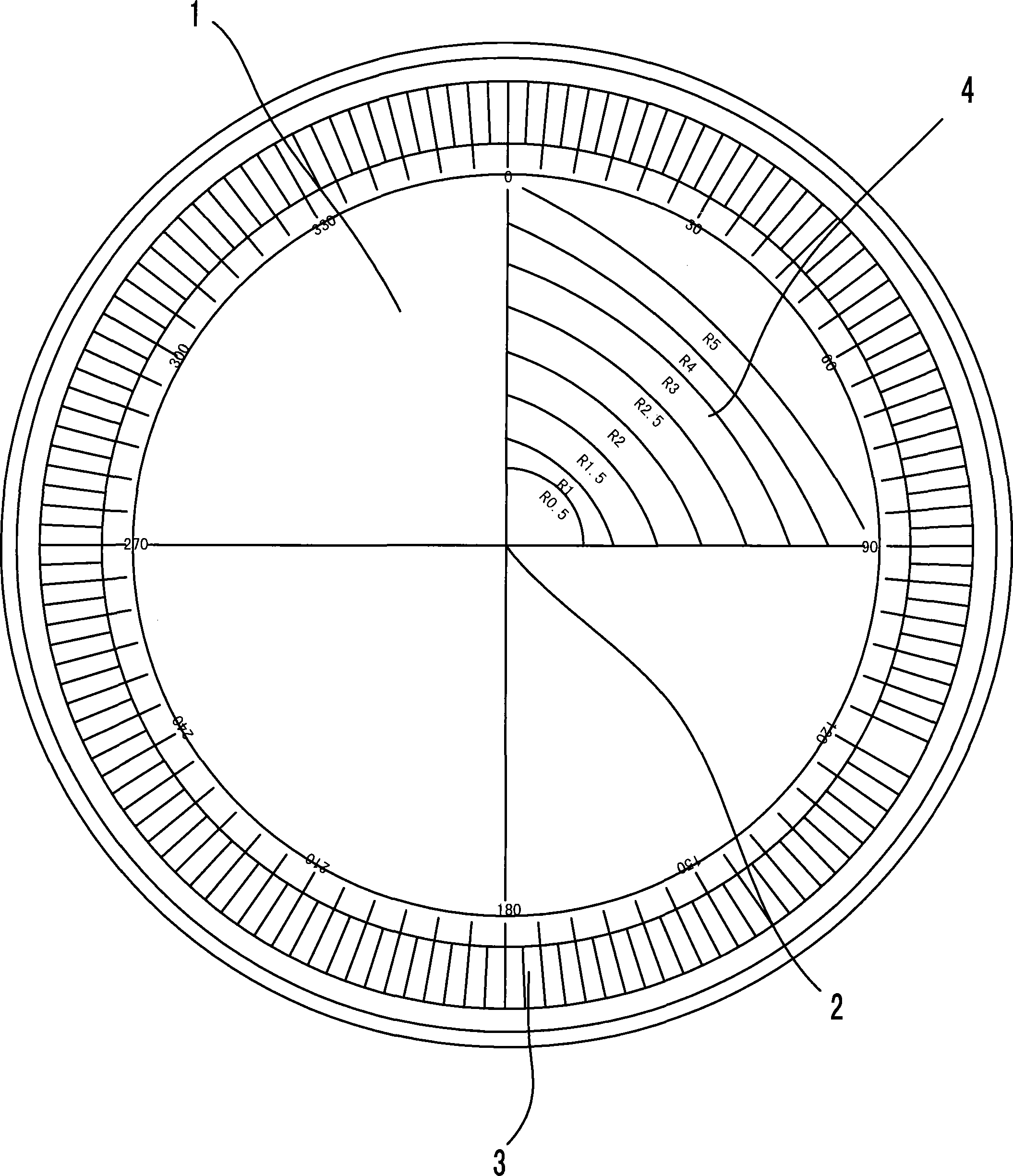

[0030] Such as figure 2 As shown, a roundness angle subdivision reticle is different from Embodiment 1 in that: the radian reticle 4 is a set of circle centers and cross lines drawn in any quadrant on the reticle body 1 Concentric radian marking lines 4 with coincident centers, the concentric radian marking lines 4 intersect with the cross line both horizontally and vertically, and the radius of the arc is consistent with the standard size of the arc radius of the tool blade. Other structures are the same as those in Embodiment 1, and will not be described in detail here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com