Treatment for wastewater of technique for producing spaston and cyclic utilization method for recycled organic matter

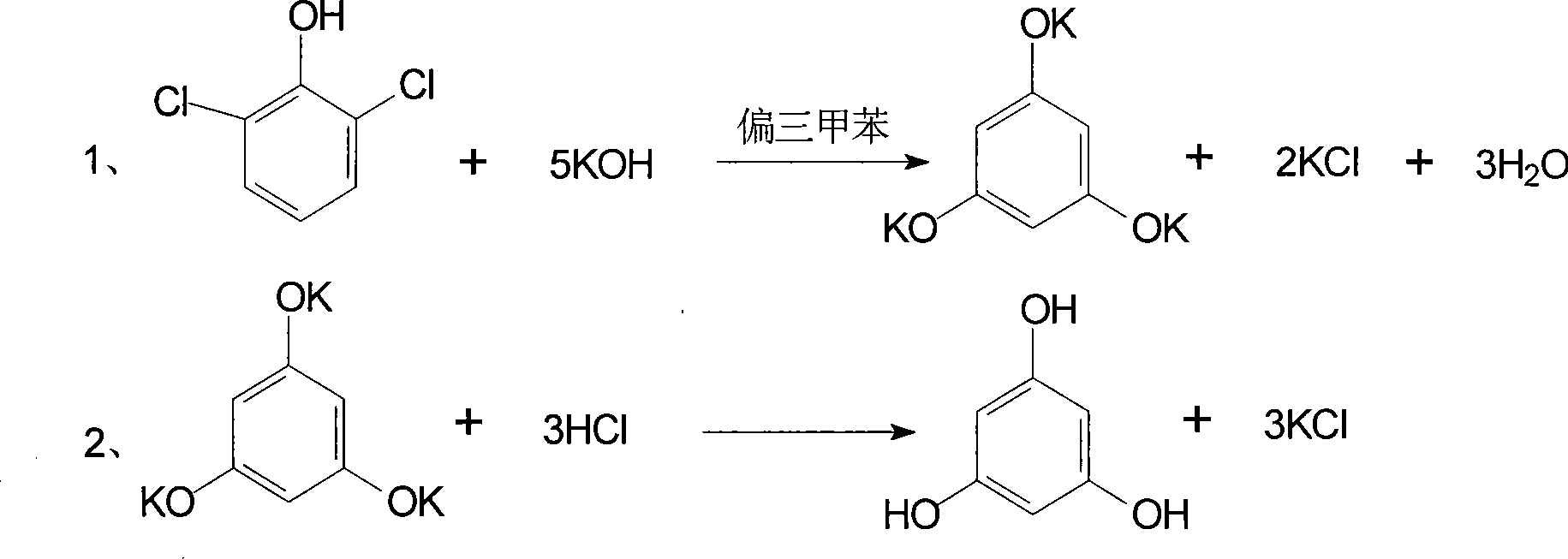

A technology of phloroglucinol and production process, which is applied in the field of treatment of phloroglucinol production process wastewater and the recycling of organic matter, which can solve the problem of high treatment costs, waste of phloroglucinol, and process wastewater that is not economical and effective. The treatment methods and other issues, to achieve the effect of saving costs, reducing pollution, and improving the effect of treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] 1. Take 40mL (about 30g, dry weight) of ZH-01 resin and fill it equally into two adsorption columns with insulation jackets (Φ20×250mm).

[0019] 2. Take 400mL dark reddish-brown phloroglucinol production process wastewater and filter to remove large particles of impurities, then add 1ml of 1% hydrochloric acid dropwise, pH is 2.5, and the column liquid COD Cr The content of phloroglucinol is 9670mg / L, and the content of phloroglucinol is 4760mg / L; at room temperature (25°C), 400ml of upper column liquid is passed through two ZH-01 adsorption columns in sequence at a flow rate of 40mL / h, and the secondary adsorption water is colorless , Phloroglucinol is 3.6mg / L, COD Cr Reduced to 440mg / L, pH 3.6;

[0020] 3. Use 40mL of 6% KOH solution to desorb and regenerate the ZH-01 adsorption column with phloroglucinol at a temperature of 40±5°C, with a flow rate of 20mL / h. The adsorption column regenerated by desorption was washed with 10 ml of 1% hydrochloric acid solution and...

Embodiment 2

[0023] 1. Take 600mL (about 450g, dry weight) of NDA150 resin and load it equally into three adsorption columns with insulation jackets (Φ35×500mm).

[0024] 2. Take 4L of deep reddish-brown process wastewater in the production of phloroglucinol and filter to remove large particles of impurities, add 10ml of 2% hydrochloric acid dropwise, and put the column solution COD Cr phloroglucinol content is 9320mg / L, pH is 2.8, and phloroglucinol content is 4570mg / L; at room temperature (25°C), 4L of upper column liquid is passed through the first and second NDA150 adsorption columns successively at a flow rate of 300mL / h, and the second Grade adsorption water is colorless, phloroglucinol is 2.4mg / L, COD Cr Reduced to 480mg / L, pH 3.6;

[0025] 3. Use 400mL of 8% KOH solution to desorb and regenerate the first NDA150 adsorption column that is adsorbed with phloroglucinol and is nearly saturated at a temperature of 45±5°C, with a flow rate of 100mL / h. The first adsorption column regene...

Embodiment 3

[0033] Repeat steps 1-8 of Example 2.

[0034] Combine the desorption liquids in the above steps 3, 5, and 7, and directly put them into the hydrochloric acid acidification step of the phloroglucinol production process as a raw material, and prepare phloroglucinol together. Tests have shown that it does not affect the product quality of phloroglucinol.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com