High temperature coke oven crude gas hydrogen generating system device and technique

A crude gas, high temperature technology, applied in the direction of hydrogen, inorganic chemistry, non-metallic elements, etc., can solve the problems of energy waste, environmental pollution, etc., and achieve the effect of saving investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

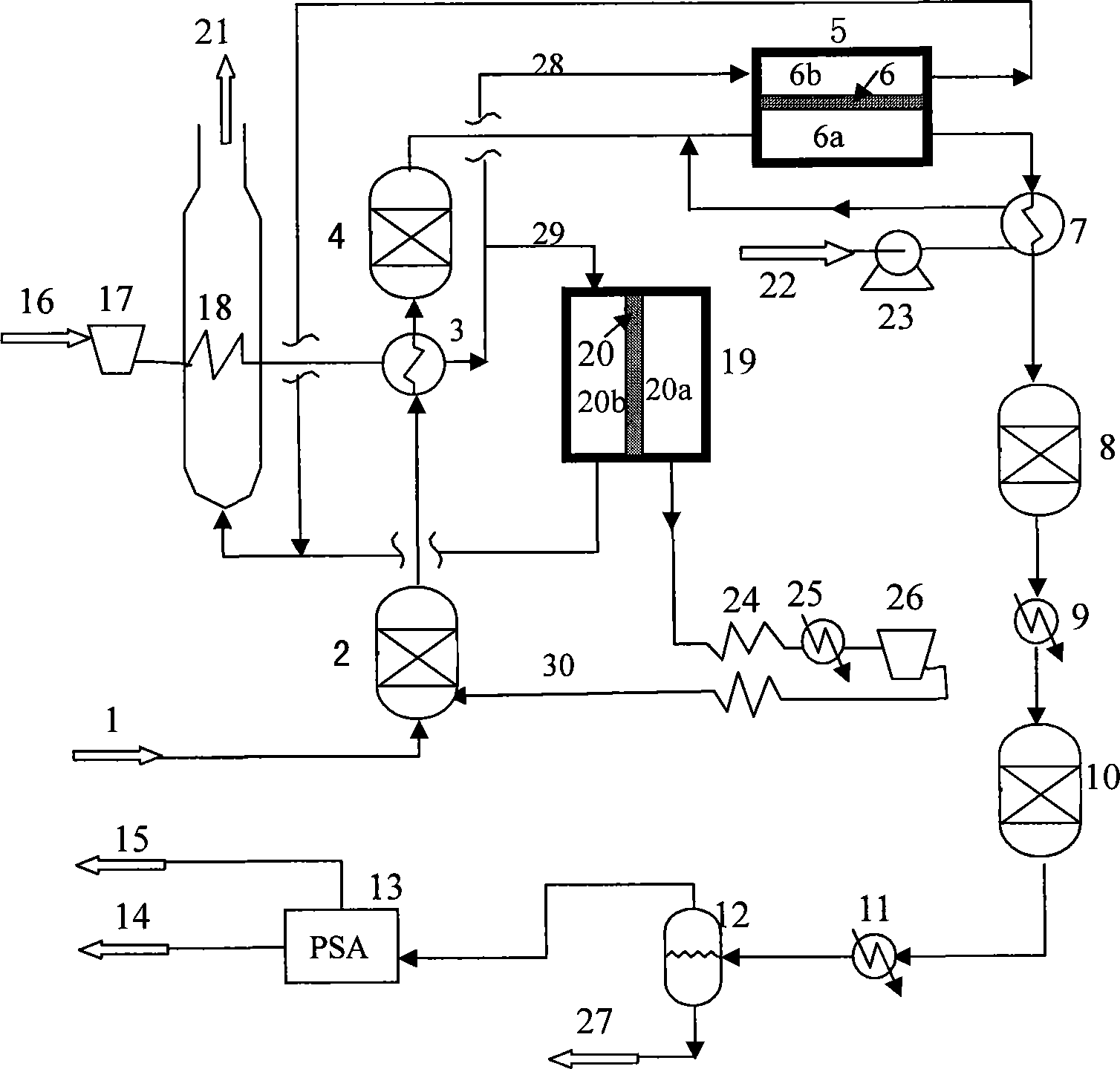

[0039] The coal gas hydrogen production system device and process flow of this embodiment can be found in figure 1 .

[0040] The system device includes a high-temperature coke oven crude gas supply system, an oxygen source air supply system, a high-temperature steam supply system, a dry gasifier oxygen supply system, a high-temperature desulfurization system, and a gas reforming reaction product output system; The structural composition of the system and the connection mode of the configured devices are as follows:

[0041] 1. Coke oven crude gas supply system: from the coke oven crude gas pipeline inlet 1 through the pipeline through the dry gasifier 2, heat exchanger 3, desulfurizer 4 and the oxygen-permeable membrane in the mixed conductor oxygen-permeable membrane reactor 5 The reforming reaction gas side space 6a below the 6 is connected;

[0042] 2. Oxygen source air supply system: the oxygen source air pipeline inlet 16 passes through the pipeline through the compres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com