Pure biological fruit-vegetable plastic wrap powder agent and preparation thereof

A fruit and vegetable fresh-keeping and biological technology, applied in the field of pure biological fruit and vegetable fresh-keeping film powder and its preparation, can solve the problems of unfavorable storage and transportation, and achieve the effects of reducing physiological consumption, optimizing biological activity, and inhibiting growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

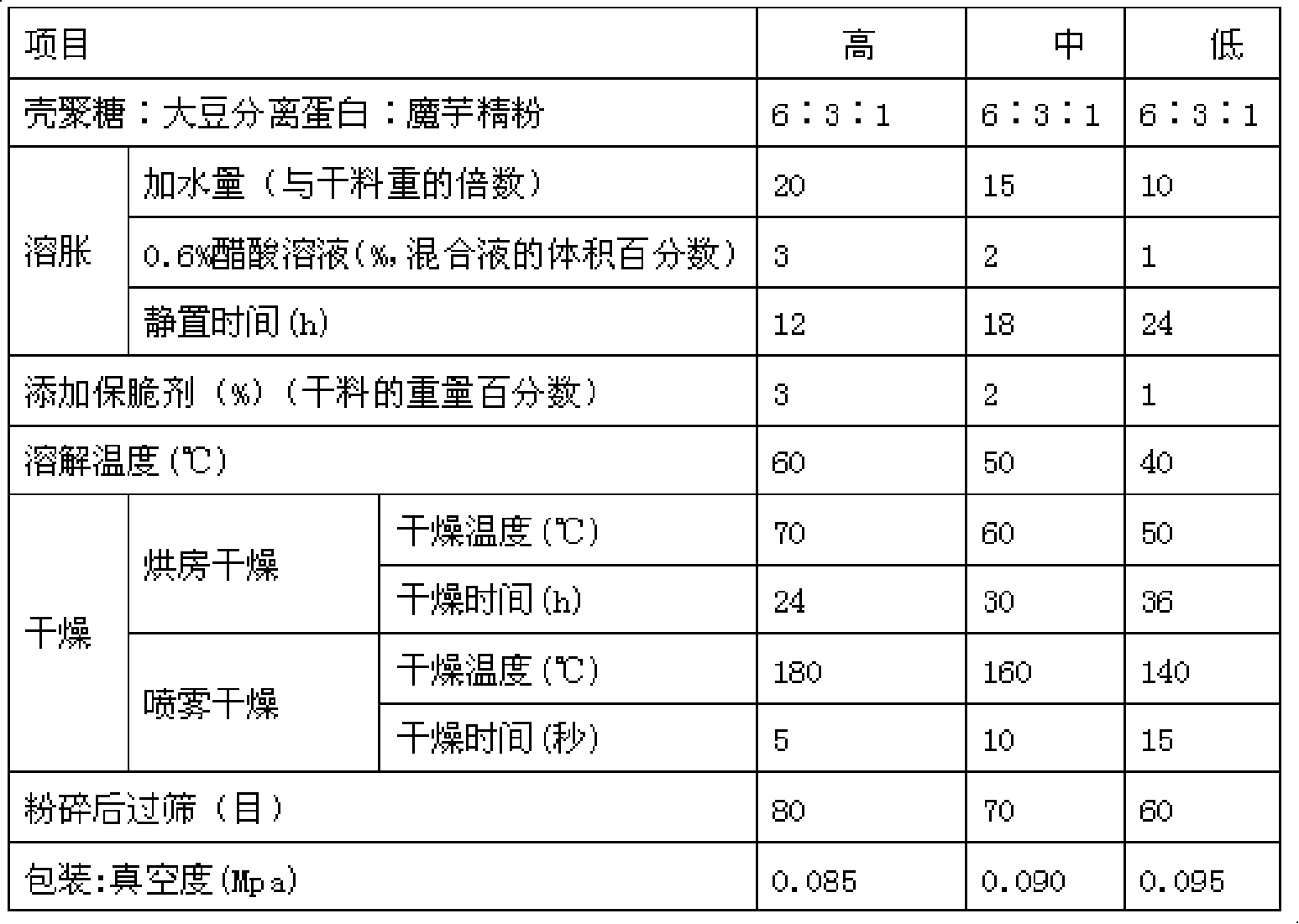

Method used

Image

Examples

Embodiment 1

[0048] Embodiment 1: chitosan 6kg, soybean protein isolate 3kg, konjaku powder 1kg, calcium chloride 0.2kg

[0049]Get the film-forming main material chitosan, soybean protein isolate and konjac fine powder and mix, add 0.6% acetic acid solution of 15 times of amount (weight) water and mixed solution 2% (volume), stir well, leave standstill, soak for 24 hours to carry out Fully swell to obtain a swelling solution, then add calcium chloride to the swelling solution, stir evenly, place in a jacketed pot with a stirrer, heat to 50°C, keep constant temperature and stir continuously until chitosan, soybean protein isolate and konjac Completely dissolve the refined powder to obtain a film thick liquid. Spray dry the film thick liquid at 140-180°C for 10 seconds until the water content is below 12%, crush it, and pass through a 60-mesh sieve to obtain pure biological fruits and vegetables. Preservative film powder is packed in vacuum with a vacuum degree of 0.090MPa, packed in corrug...

Embodiment 2

[0054] Embodiment 2: chitosan 5kg, soybean protein isolate 3.5kg, konjaku powder 0.8kg, calcium chloride 0.15kg

[0055] Get the film-forming main material chitosan, soybean protein isolate and konjac fine powder to mix, add 0.6% acetic acid solution of 10 times of amount (weight) water and mixed solution 1% (volume), stir well, leave standstill, soak 12 hours fully Swell to obtain a swelling solution, add calcium chloride to the swelling solution, stir evenly, and then fully dissolve at 60°C to obtain a thick film solution, dry the thick film solution in a drying room at 50-70°C for 30 hours to water The part content is below 12%, pulverized, and passed through an 80-mesh sieve to obtain pure biological fruit and vegetable preservative film powder. The preservative film powder is vacuum-packed, and the vacuum degree is 0.095MPa. The preservative film powder after vacuum packaging can be stored at room temperature for more than 1 year.

Embodiment 3

[0056] Embodiment 3, chitosan 7kg, soybean protein isolate 2.5kg, konjaku powder 1.kg, calcium chloride 0.3kg

[0057] Get the film-forming main material chitosan, soybean protein isolate and konjac fine powder to mix, add 0.6% acetic acid solution of 12 times of amount (weight) water and mixed solution 1.5% (volume), stir well, leave standstill, soak 20 hours fully Swell to obtain a swelling solution, add calcium chloride to the swelling solution, stir evenly, place in a jacketed pot with a stirrer, heat to 50°C, keep constant temperature and stir continuously until chitosan, soybean protein isolate and konjac powder Completely dissolve to get pure biological fruit and vegetable preservative film agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com