Chilled-mirror type dew point instrument control method

A control method and technology of dew point meter, applied in the direction of electric controller, material water content, etc., can solve the problems of too thin frost layer, heat accumulation at the hot end of the cold pump, system oscillation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

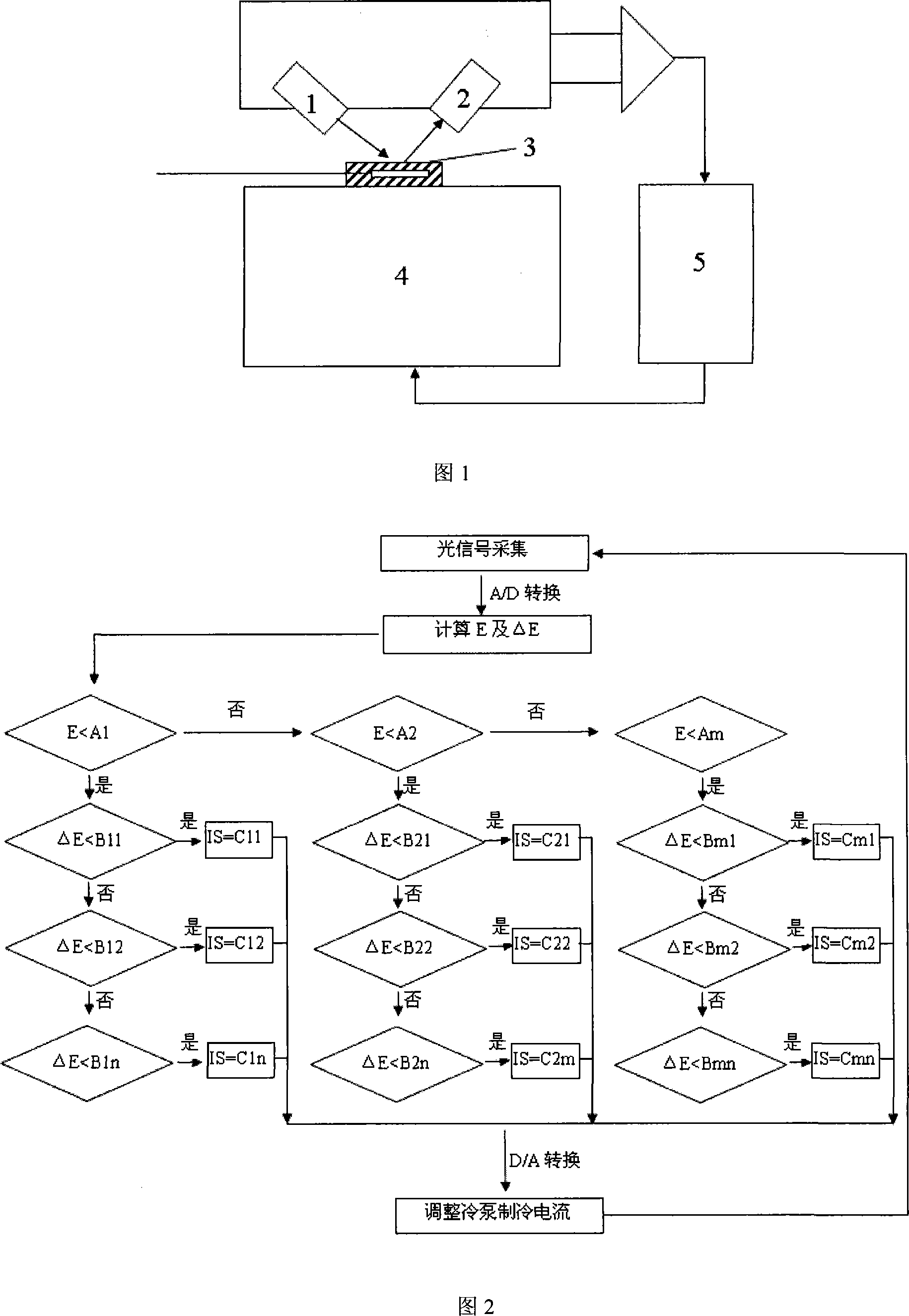

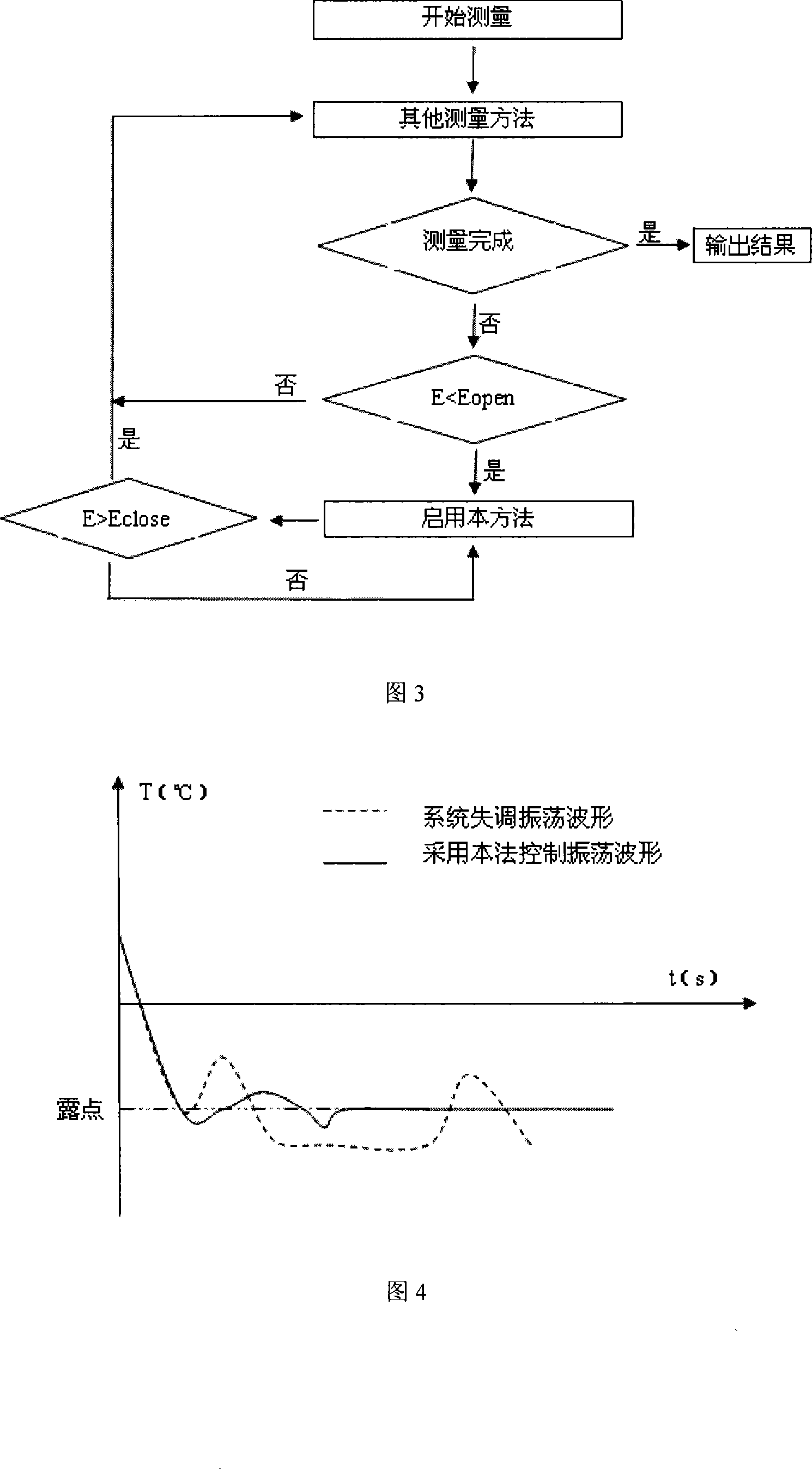

[0013] Figure 1 is a schematic cross-sectional view of the dew point measurement chamber of the chilled mirror dew point meter. The luminous tube 1 emits light, and the cold pump 4 cools down. The thickness of the frost layer on the mirror surface 3 affects the light energy received by the receiving tube 2 . This method is a method of controlling the current of the cold pump 4 step by step after performing data calculation by the processor 5 so as to accurately control the temperature of the mirror surface 3 to control the thickness of the frost layer.

[0014] Fig. 2 and Fig. 3 show the flow diagram of this method to control the current step by step and the flow diagram when it is used in combination with other measurement methods. The light energy reflected or scattered by the photoelectric sensor receiving tube 2 senses the light energy reflected or scattered by the frost layer and outputs an electrical signal, and the processor, etc. The electrical signal converted by A / D ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com