Butterfly flap type blast engine

A butterfly flapping and blower technology is applied in the field of butterfly flapping blowers, which can solve the problems of high cost, difficulty in further increasing wind pressure, and large gas leakage rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

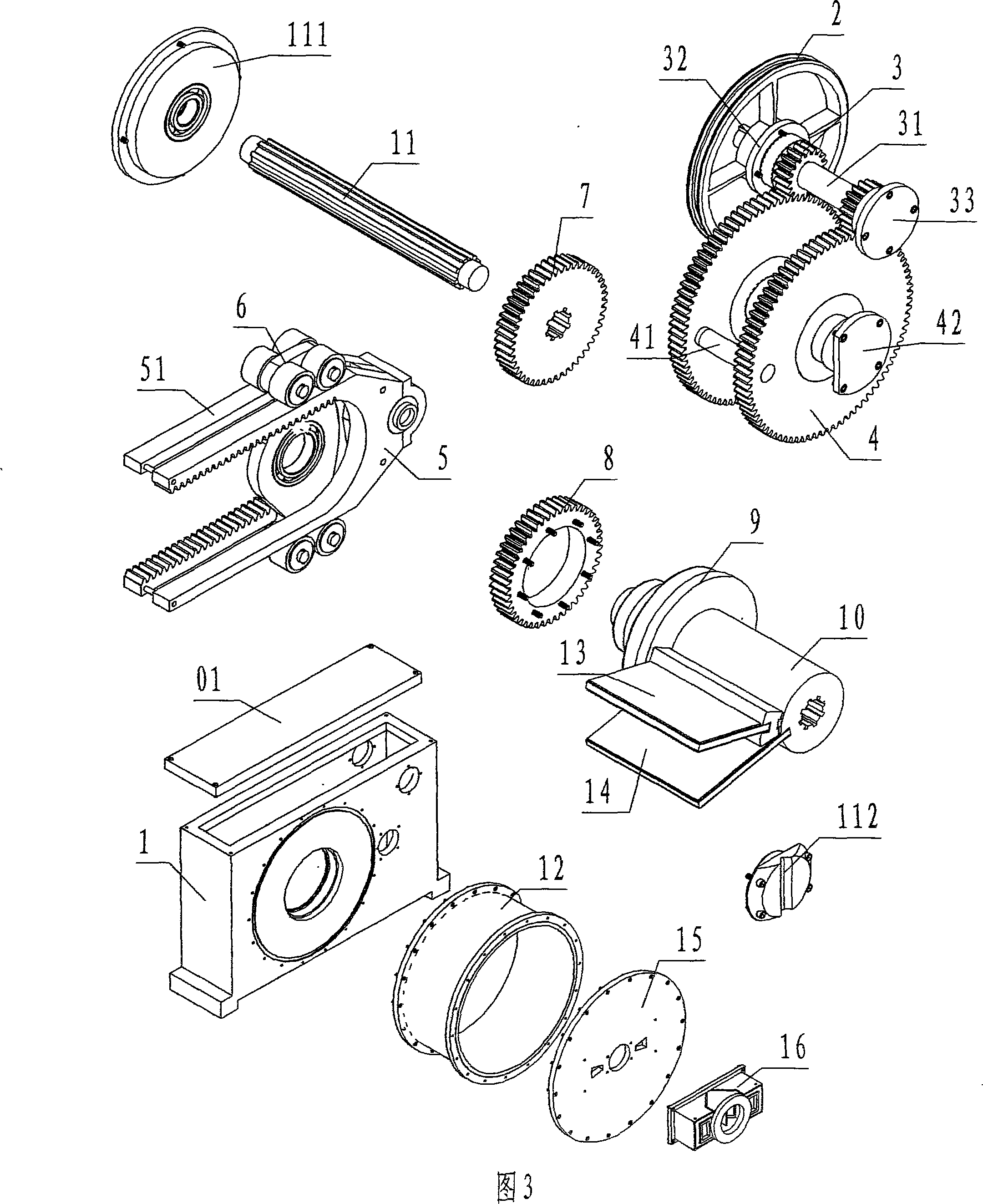

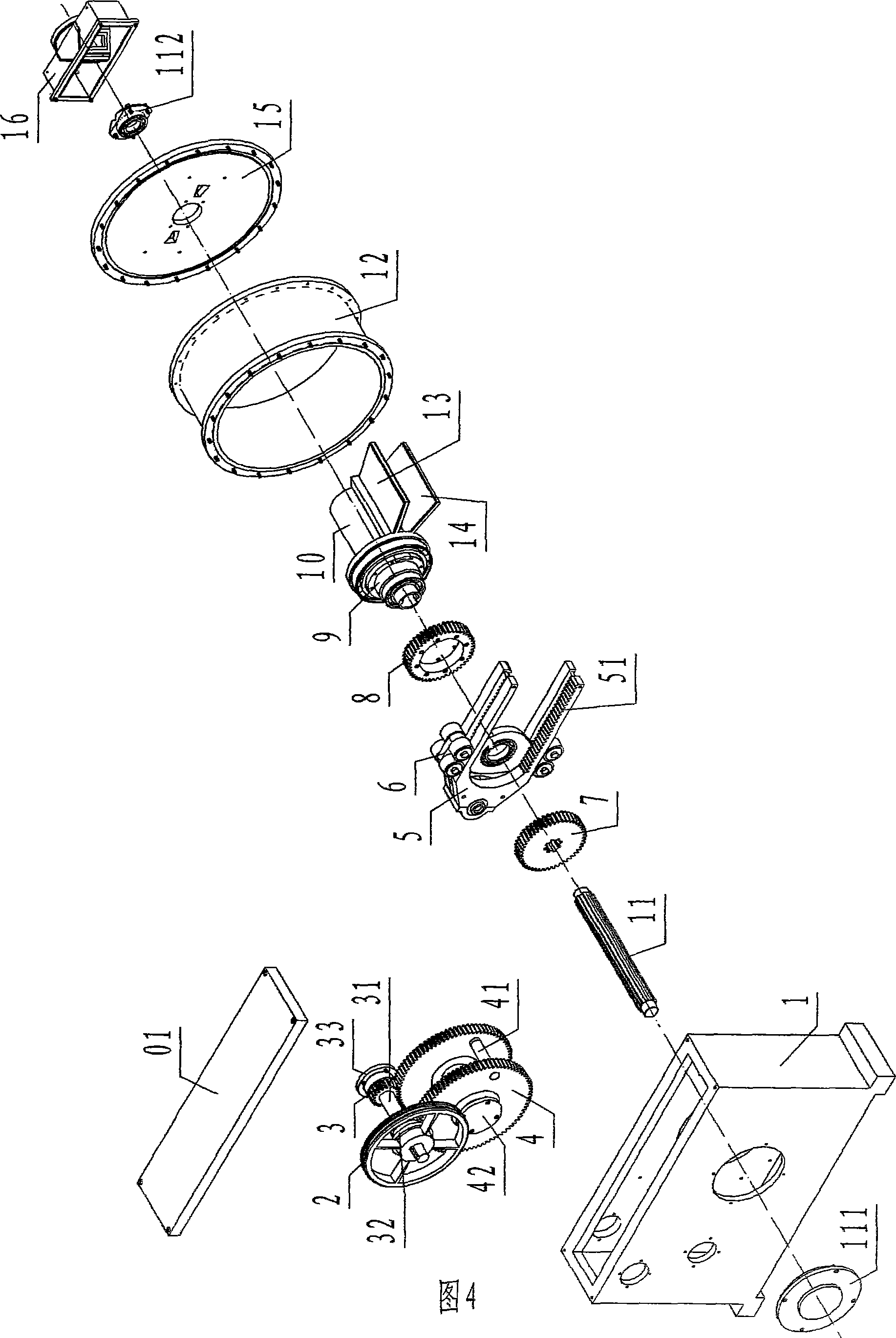

[0020]Referring to Fig. 1, Fig. 2 and Fig. 3, a butterfly flutter blower of the present invention includes a gear box 1, a pulley 2, a reduction gear 3, a reduction gear shaft 31, a crankshaft gear 4, a crankshaft 41, a rack assembly 5, and a pressure wheel Component 6, spline gear 7, sleeve shaft gear 8, end face sleeve shaft 9, spline sleeve shaft 10, spline shaft 11, casing 12, end face sleeve shaft blade 13, spline sleeve shaft blade 14, cover plate 15, Air valve 16, wherein: the gear box 1 is a steel plate welded or cast iron rectangular box with open front and rear side walls with several bearing holes and shaft holes, and is equipped with a box cover 01; the pulley 2 is a V-belt pulley with a shaft hole with a keyway at the center of cast iron; the reduction gear 3 is a cylindrical involute spur gear with a shaft hole with a keyway at the center of cast iron or steel; the reduction gear shaft 31 is that one end is provided with a cylindrical step with a keyway and a cyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com