Large wind wheel single-stage wheel gear power generation

A power generation device and gear technology, which is applied in electromechanical devices, wind power generation, wind engines, etc., can solve problems such as heavy transmission system chains, and achieve the effect of simplifying energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

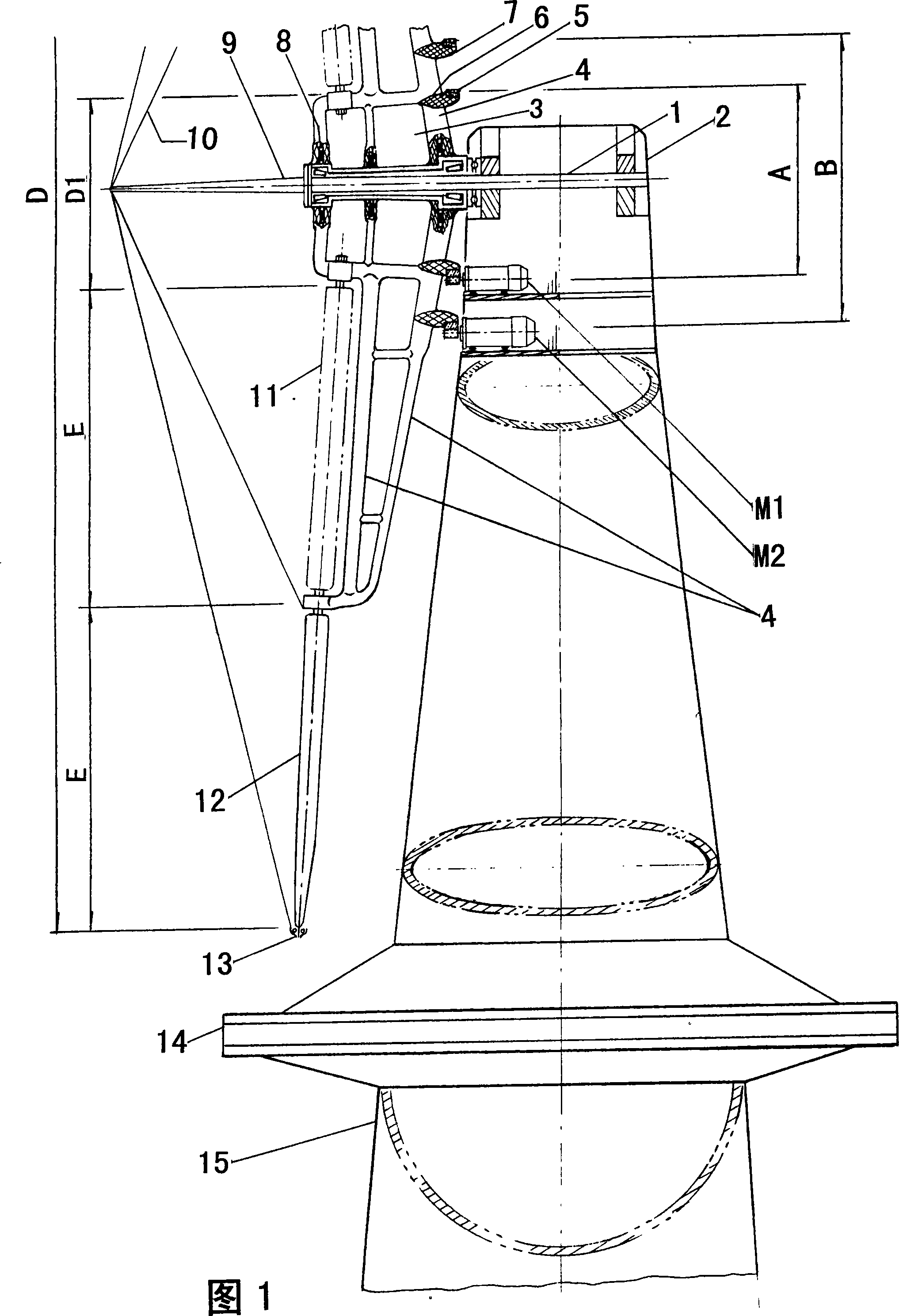

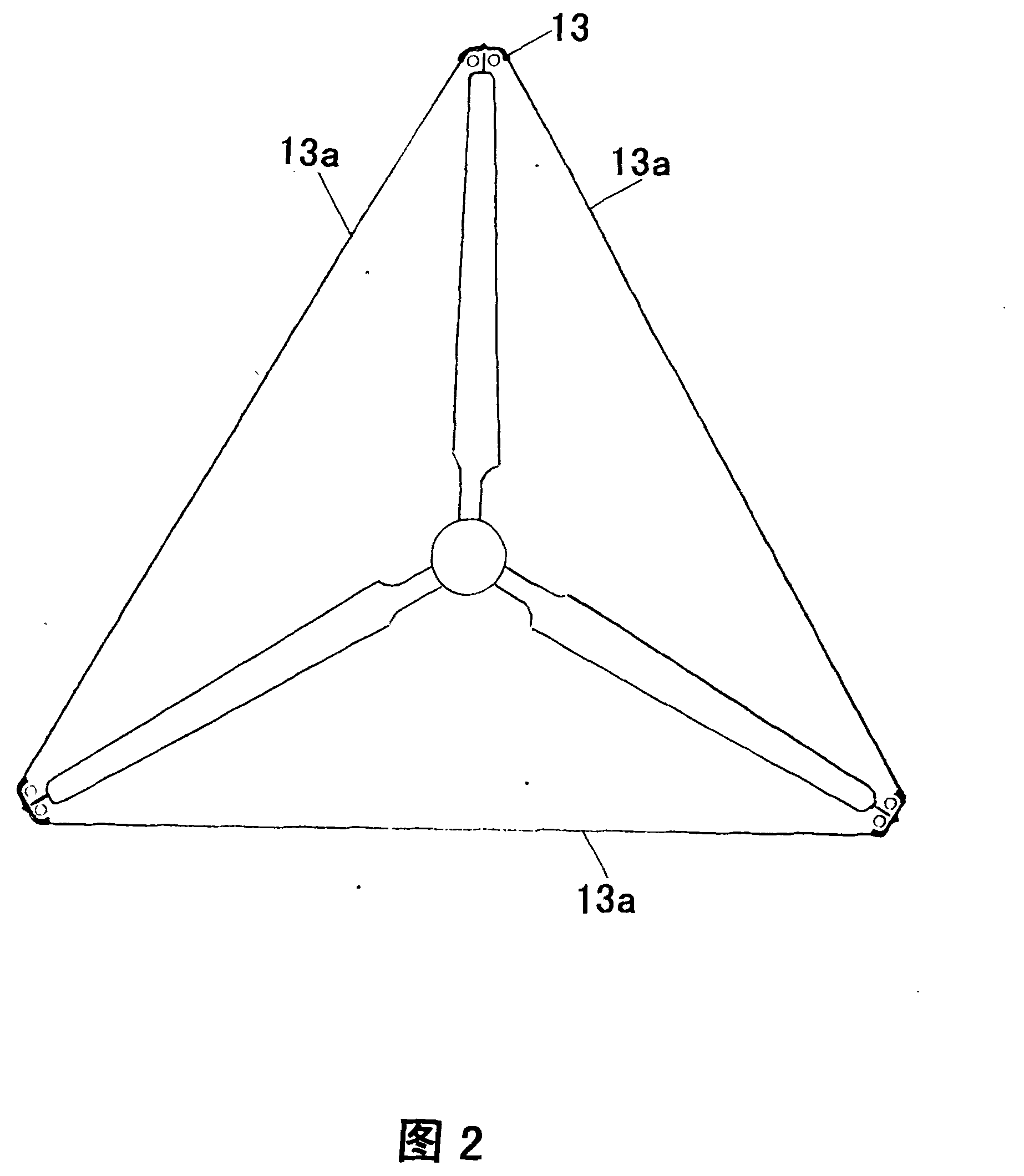

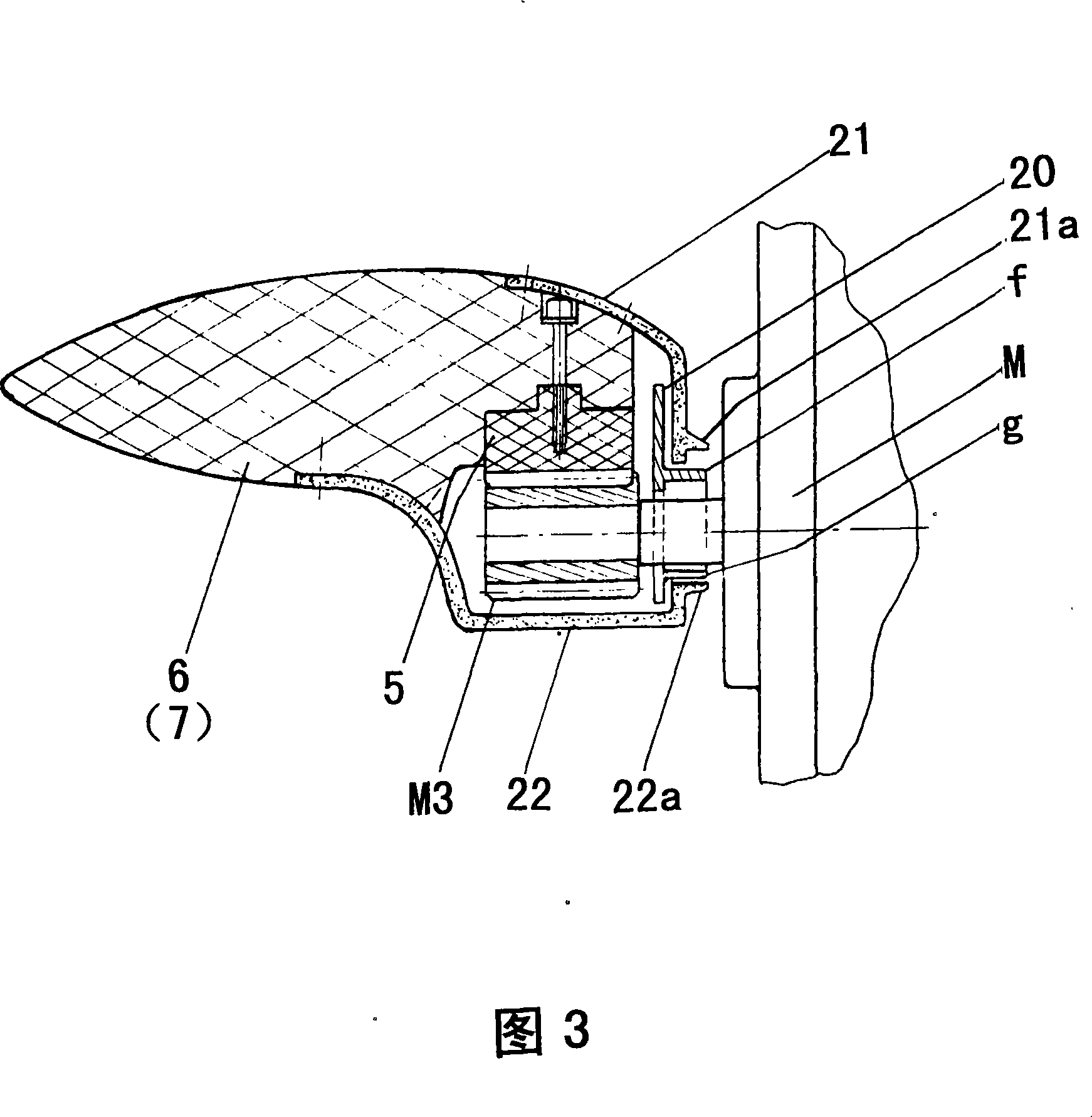

[0009] see figure 1 , the main shaft 1 is fastened in the tower head 2, the main shaft does not rotate, it only plays the role of supporting the center of the wind wheel, and no longer serves as a transmission. Wheel hub 3 can rotate freely through bearings. Three pairs of wheel stays 4 with a distance of 120° are arranged on the outer cylindrical surface of the wheel hub 3 (for the convenience of the view, the upper and lower wheel stays 4 of the wheel hub 3 are developed into a symmetrical layout view), and the inner and outer ring gears 5 are respectively installed on the On the inner ring 6 and the outer ring 7, and make the pitch circle diameter A=30m of the ring gear on the inner ring, and the pitch circle diameter B=45m of the ring gear on the outer ring. Now use the ring gear pitch circle A (①30m) to drive the generator M1, and the ring gear pitch circle B (Φ45m) to drive the generator M2 (both cooperating with the small teeth on each generator shaft respectively).

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com