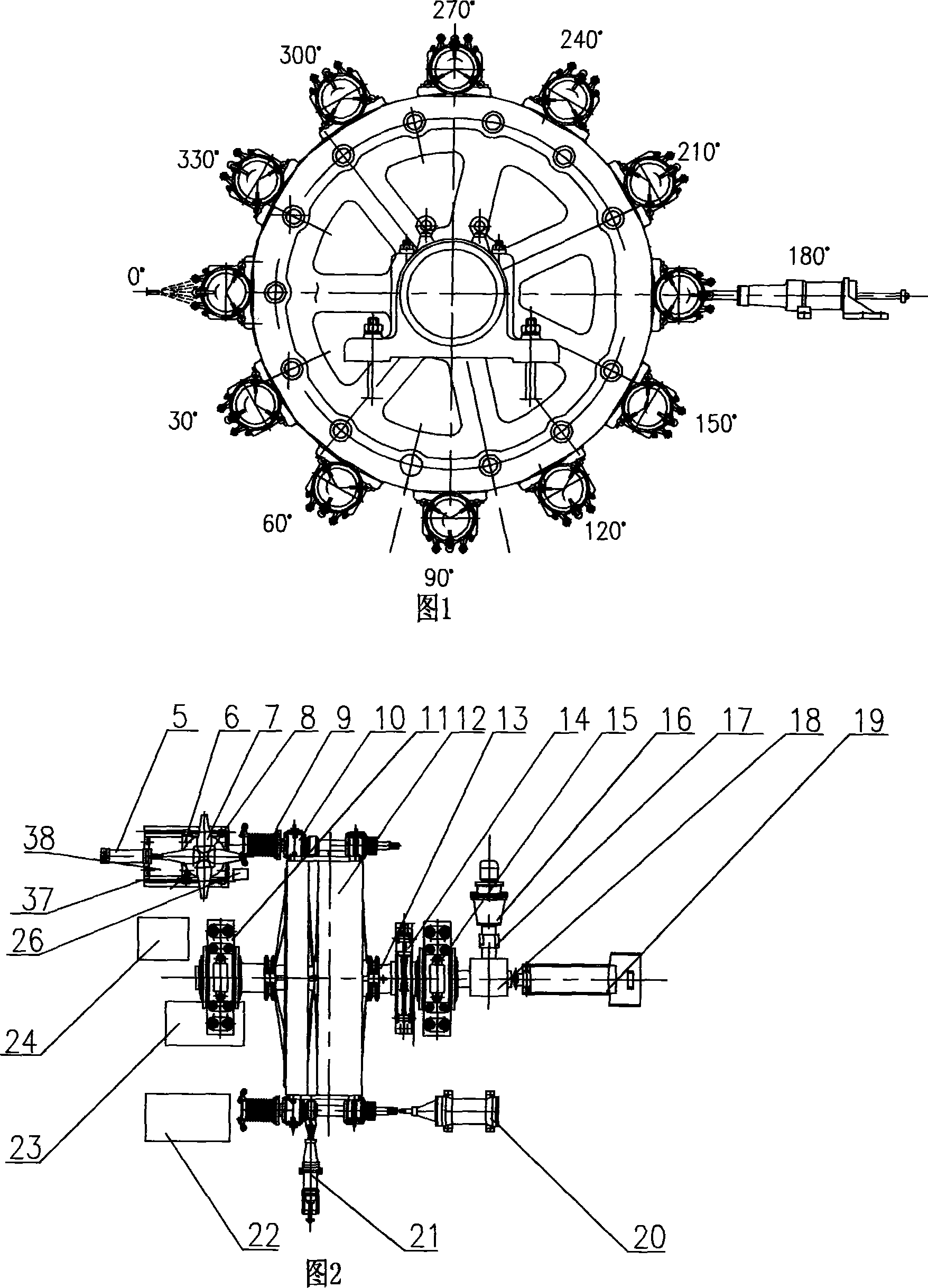

Full-automatic twelve-station centrifugal casting machine

A centrifugal casting, twelve-station technology, applied in the direction of tools, manufacturing tools, metal processing equipment, etc., can solve problems such as unavailability, and achieve the effect of improving quality, reducing personnel burden, and improving safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

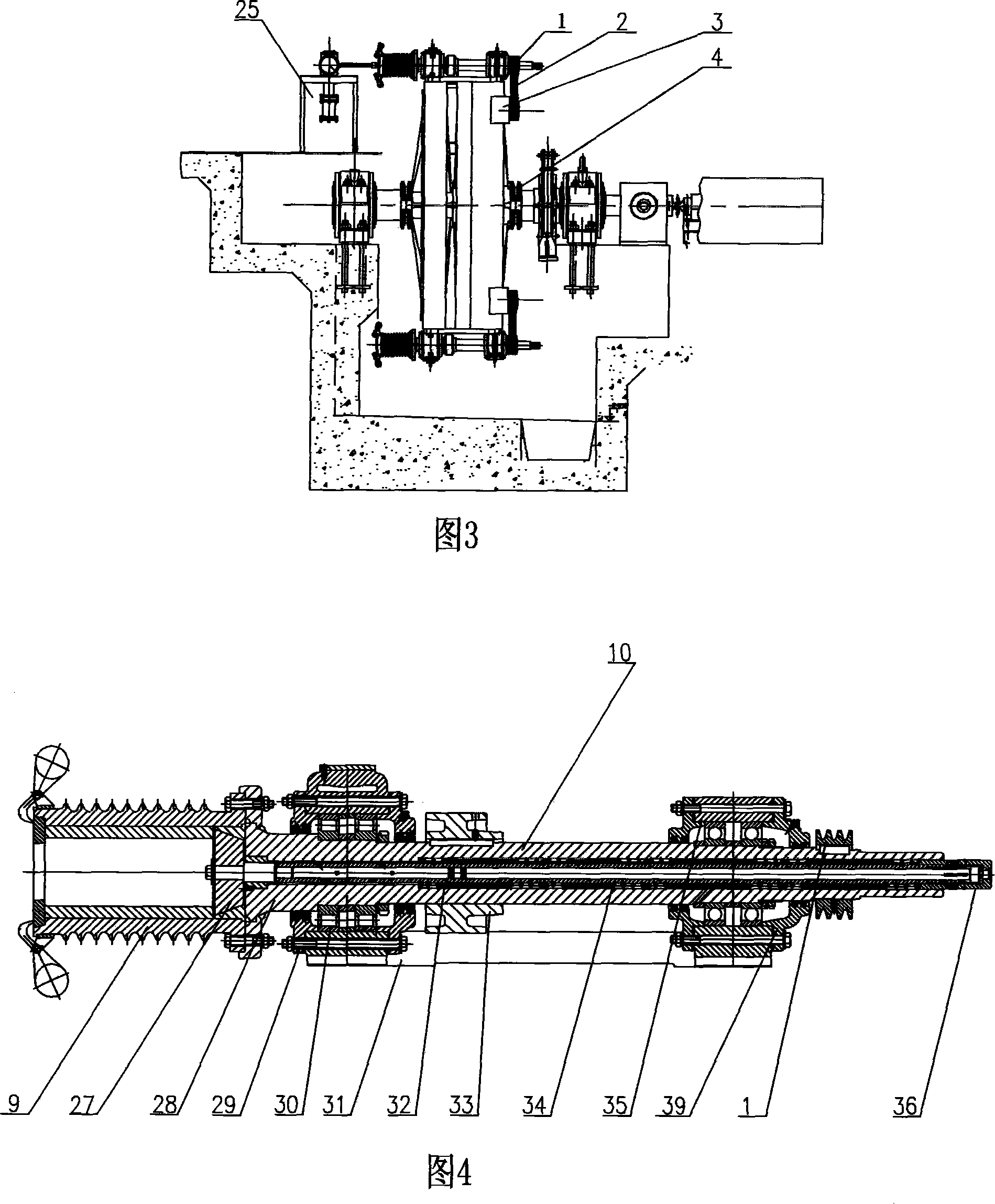

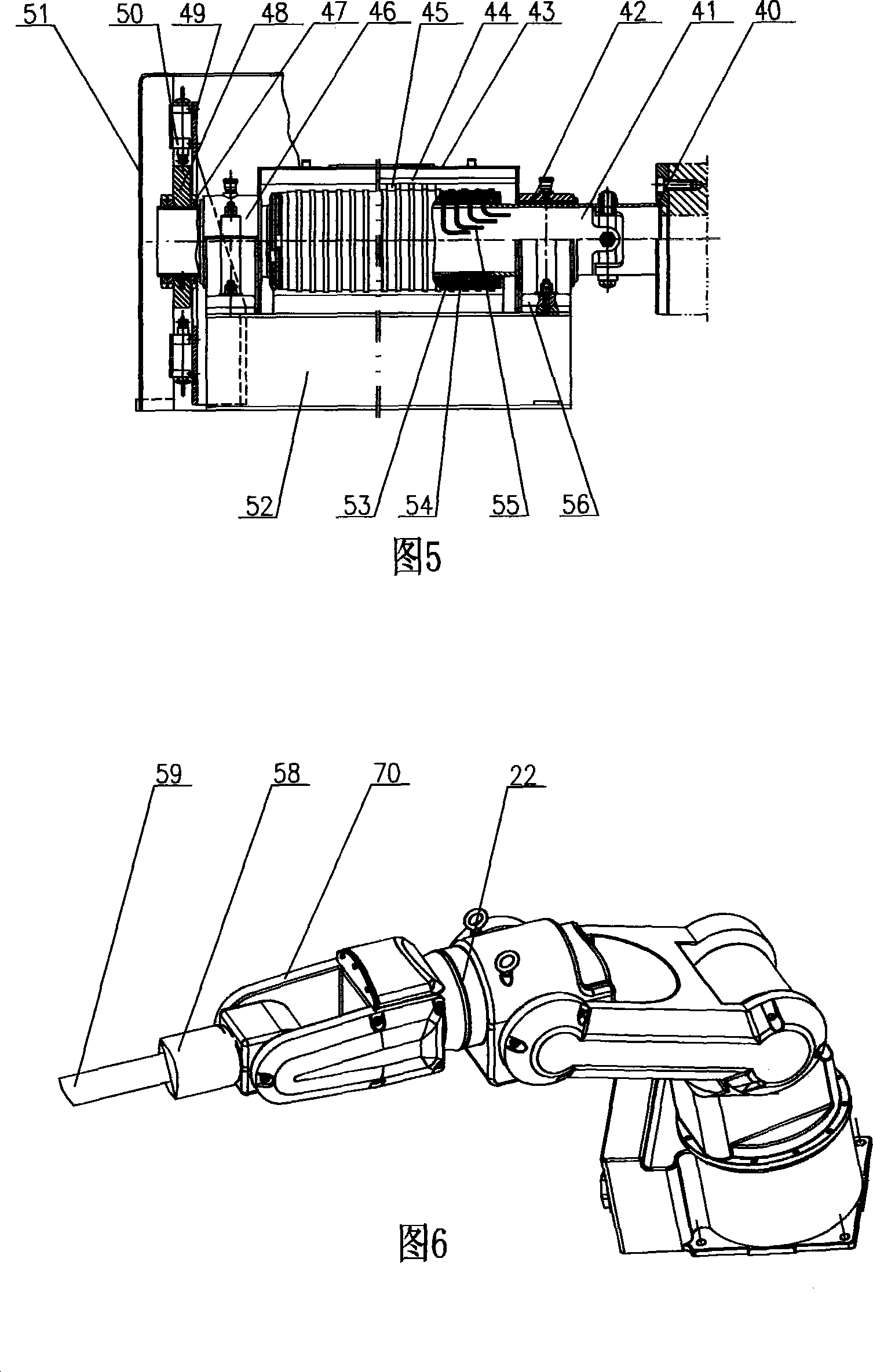

[0028] The embodiments of the present invention are described in detail below in conjunction with the accompanying drawings: this embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following the described embodiment.

[0029] As shown in Figures 1-3, this embodiment includes: a pulley 1, a V-belt 2, a first motor 3, a first lock nut 4, a cylinder liner mold 9, a centrifugal casting machine 10, a front bearing seat 11, a large plate 12, Main shaft 13, damping mechanism 14, rear bearing seat 15, reducer 16, second motor 57, coupling 17, cam arc surface equalization mechanism 18, slip ring mechanism 19, cylinder liner ejection cylinder 20, brake cylinder 21 , Take cylinder liner manipulator device 22, mold cleaning and asbestos plate loading mechanism 23, upper door panel device 24, pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com