Hybrid drive device

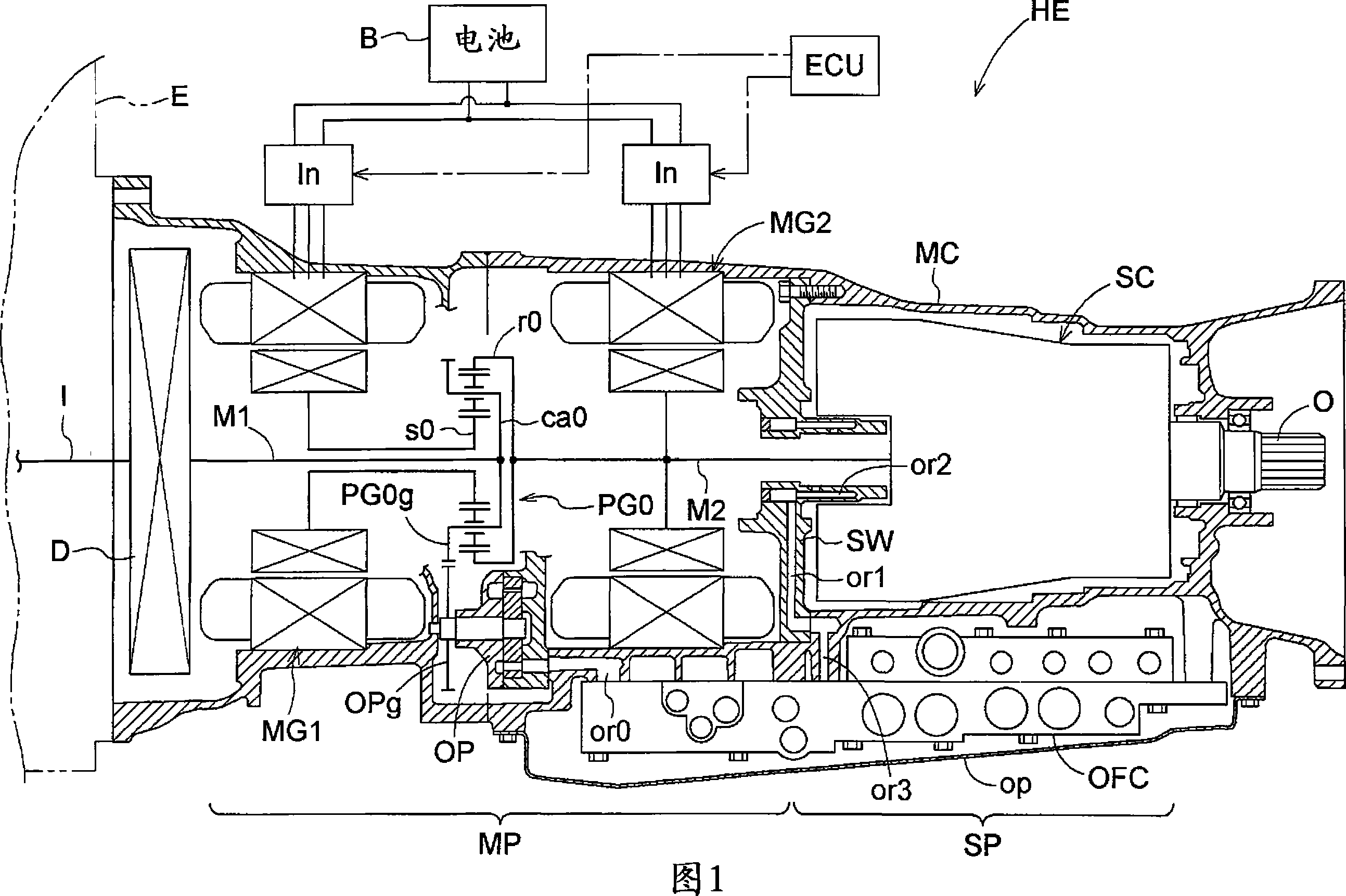

A driving device and hybrid technology, applied in power devices, electric power devices, hybrid vehicles, etc., can solve the problems of inability to continuously change the engine speed, inability to increase the input speed, poor fuel efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

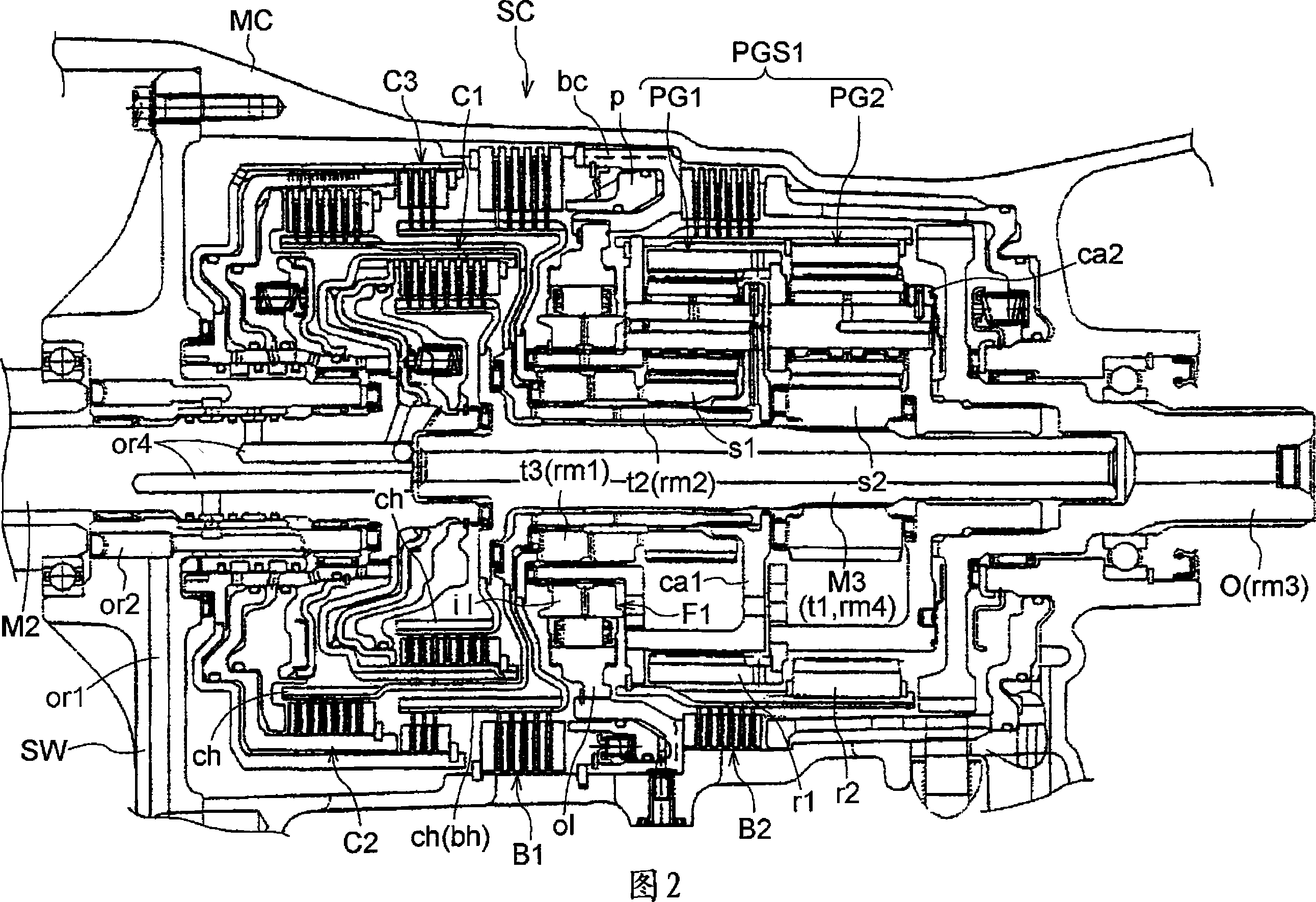

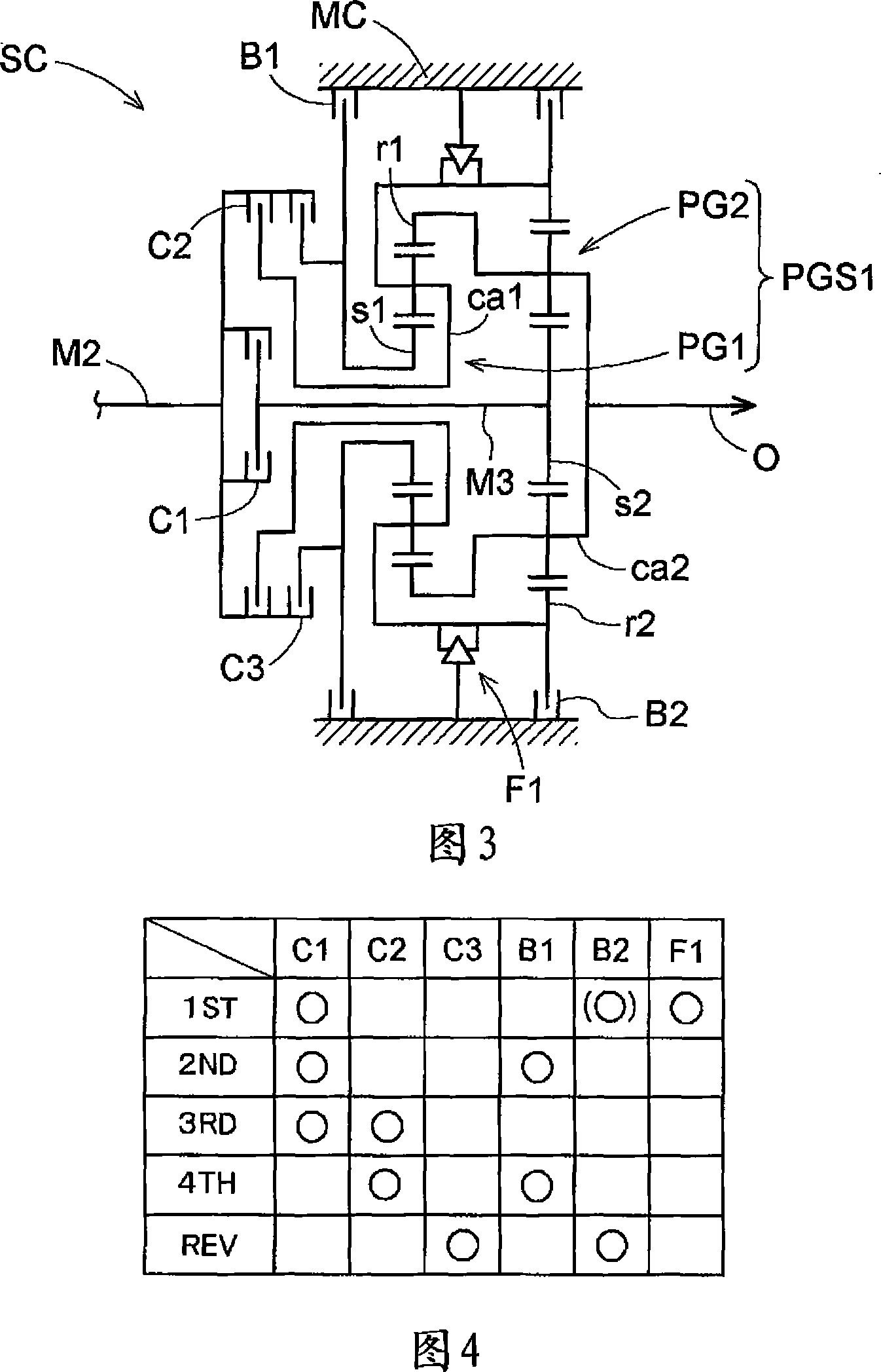

[0145] FIG. 2 shows a specific configuration of the rear of the transmission of this embodiment, and FIG. 3 shows a schematic diagram.

[0146] As can be seen from these figures, the transmission SC is configured to include a planetary gear set PGS1 composed of a pair of single planetary gears PG1 and PG2, and has a plurality of friction engagement elements C1 and C2 corresponding to the rotation elements constituting the planetary gear set PGS1. , C3, B1, B2, F1.

[0147] As friction engagement elements, a first clutch C1, a second clutch C2, and a third clutch C3, a first brake B1, and a second brake B2 are provided, and a one-way clutch F1 is provided. FIG. 4 shows an operation table of these frictional engagement elements.

[0148] drive transmission

[0149] Based on Fig. 3 as a skeleton diagram, Fig. 4 as an operation table of frictional engagement elements, the diagram on the right side of Fig. 5 as a speed diagram, Fig. 6 showing the driving transmission state of eac...

no. 2 approach

[0194] FIG. 8 shows the specific structure of the rear end of the transmission SC in this embodiment, and FIG. 9 shows its skeleton diagram. The difference between this embodiment and the first embodiment will be described. In the first embodiment, the first clutch C1 is disposed between the second electric motor MG2 and the planetary gear set PGS1 . A clutch C1 is arranged on the output shaft O side of the planetary gear set PGS2.

[0195] In this example, the second intermediate shaft M2 and the third intermediate shaft M3 are coupled to rotate integrally by a spline shaft. In addition, the output from the carrier ca2 of the second planetary gear PG2 is transmitted to the output shaft O via the output drum OD and the fourth intermediate shaft M4 rotatably provided integrally therewith.

[0196] Therefore, the skeleton diagram becomes as shown in FIG. 9 , and the operation table of the friction engagement element is the same as the table shown in FIG. 4 . In addition, the v...

no. 3 approach

[0208] Based on FIG. 10 which is a skeleton diagram of the third embodiment, FIG. 4 which is a friction engagement element operation table, and FIG. 11 which is a velocity diagram, first, the drive transmission of this embodiment will be described.

[0209] In this embodiment, when the pair of planetary gears PG constituting the planetary gear set PGS3 serving as the planetary gear set for shifting is also referred to as the first gear in order from the second intermediate shaft M2 serving as the input member of the transmission SC toward the output shaft O, When the planetary gear PG1 and the second planetary gear PG2 are used, these planetary gears are single planetary gears respectively provided with sun gears s1 , s2 , carriers ca1 , ca2 , and ring gears r1 , r2 .

[0210] When describing the relationship with the frictional engagement coefficient, the following structure is adopted, that is, the ring gear r1 of the first planetary gear PG1 is selectively fixed to the trans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com