Lithium ion battery negative pole active materials and battery

A negative active material, lithium-ion battery technology, applied in the direction of battery electrodes, secondary batteries, circuits, etc., can solve the problems of battery pack failure, reverse battery charging, battery over-discharge, etc., to delay the speed, avoid or reduce damage , Excellent anti-overdischarge performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

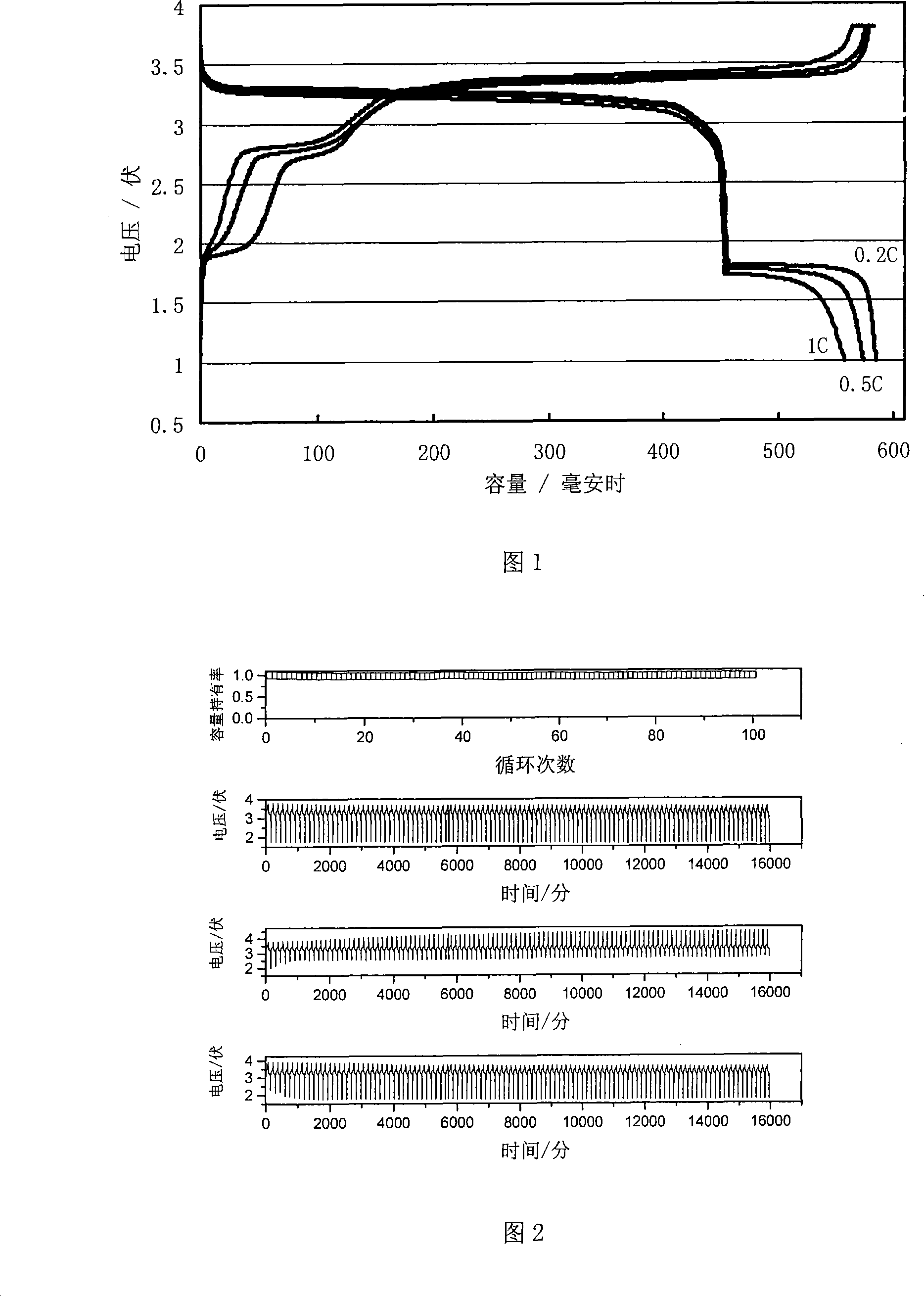

[0027] LiFePO 4 As the positive electrode active material, carbon black is used as a conductive agent, polyvinylidene fluoride (PVDF) is used as a binder, and the weight ratio is 85:10:5, and the above mixture is dispersed in N-methylpyrrolidone (NMP) to prepare a slurry. Spread the slurry evenly on the aluminum foil, dry, roll, and cut into the desired shape.

[0028] Graphite and Li 4 / 3 Ti 5 / 3 o 4 (7:3, w / w) as the active material, acetylene black as the conductive agent, polyvinylidene fluoride (PVDF) as the binder, prepared in N-methylpyrrolidone (NMP) according to the weight ratio of 80:15:5 slurry. Coat the slurry evenly on the copper foil, dry, roll, and cut into the desired shape. Graphite / (graphite and Li 4 / 3 Ti 5 / 3 o 4 ) The mass mixing ratio is between 0.05-0.5.

[0029] The electrolyte is 1M LiPF 6 - EC / DMC (70:30, v / v). A porous polypropylene membrane was used as a separator to fabricate AA cylindrical lithium-ion secondary batteries by conventional met...

Embodiment 2

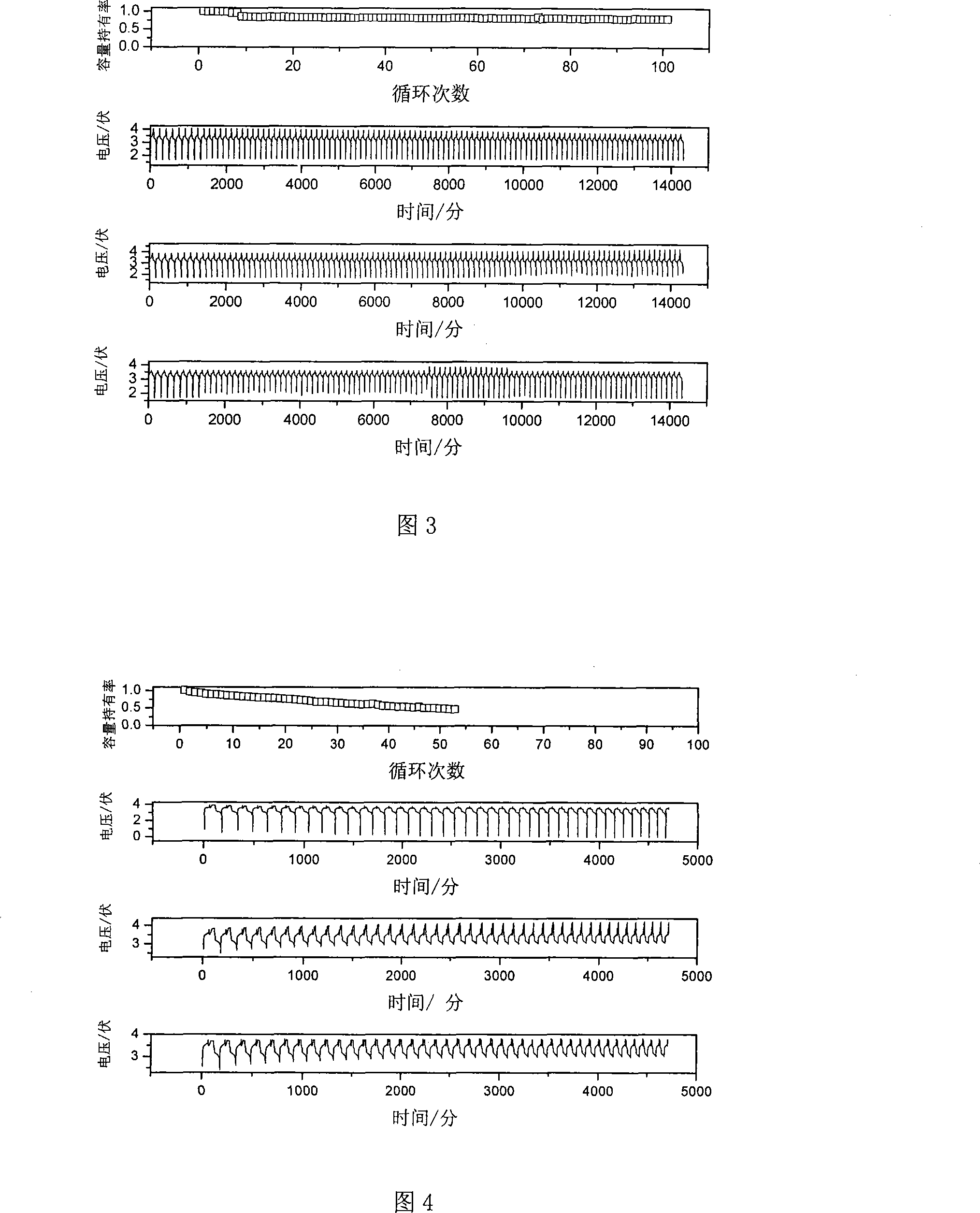

[0032] Take the consistent matching batteries made in Example 1, and connect three in series to form a battery pack. Carry out a 1C charge-discharge cycle on the battery pack, the charge-discharge cut-off voltage is 11.4-6V, and monitor the voltage of three monomers at the same time, the results are shown in Figure 2. In 100 cycles, the voltage of the three batteries at the end of each cycle discharge is above 1.5V, and there is no phenomenon of over-discharge and reverse polarity. After 100 cycles, the capacity retention of the battery pack was 95%.

Embodiment 3

[0034] Take the consistent matching batteries made in Example 1, and connect three in series to form a battery pack. Carry out a 1C charge-discharge cycle on the battery pack, the charge-discharge cut-off voltage is 11.4-5V, and monitor the voltage of three monomers at the same time, the results are shown in Figure 3. In 100 cycles, the voltage of the three batteries at the end of each cycle discharge is above 1.5V, and there is no phenomenon of over-discharge and reverse polarity. After 100 cycles, the capacity retention of the battery pack was 85%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com