Laser measuring instrument for railway work lifting and lining path

A laser measuring instrument and railway engineering technology, applied in the field of measuring instruments, can solve the problems that the detection method cannot meet the requirements of the railway engineering department for construction operations and daily line inspection, the measurement accuracy is poor, and the labor intensity is high, and the daily line maintenance is convenient. The effect of using, reducing labor intensity and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

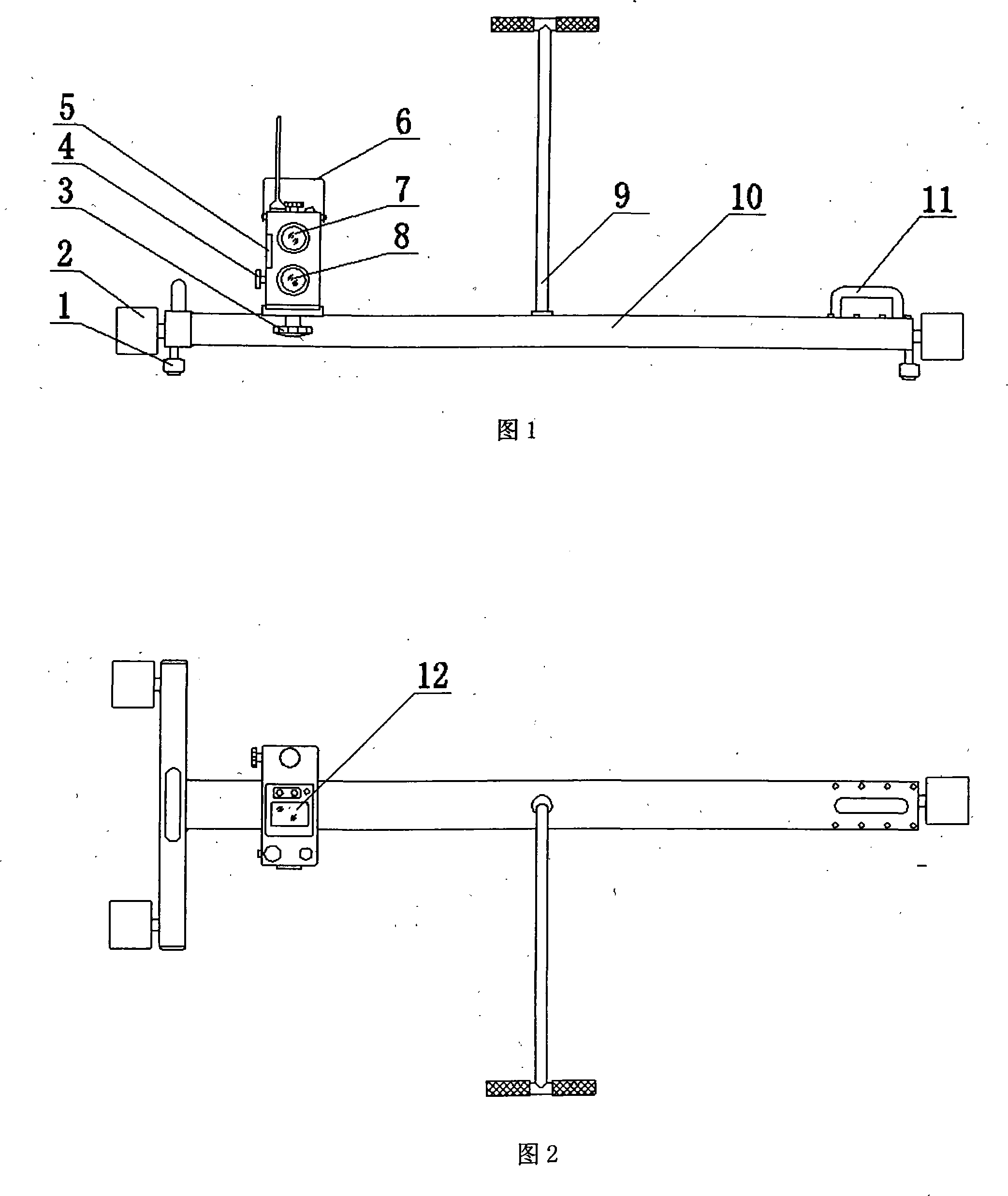

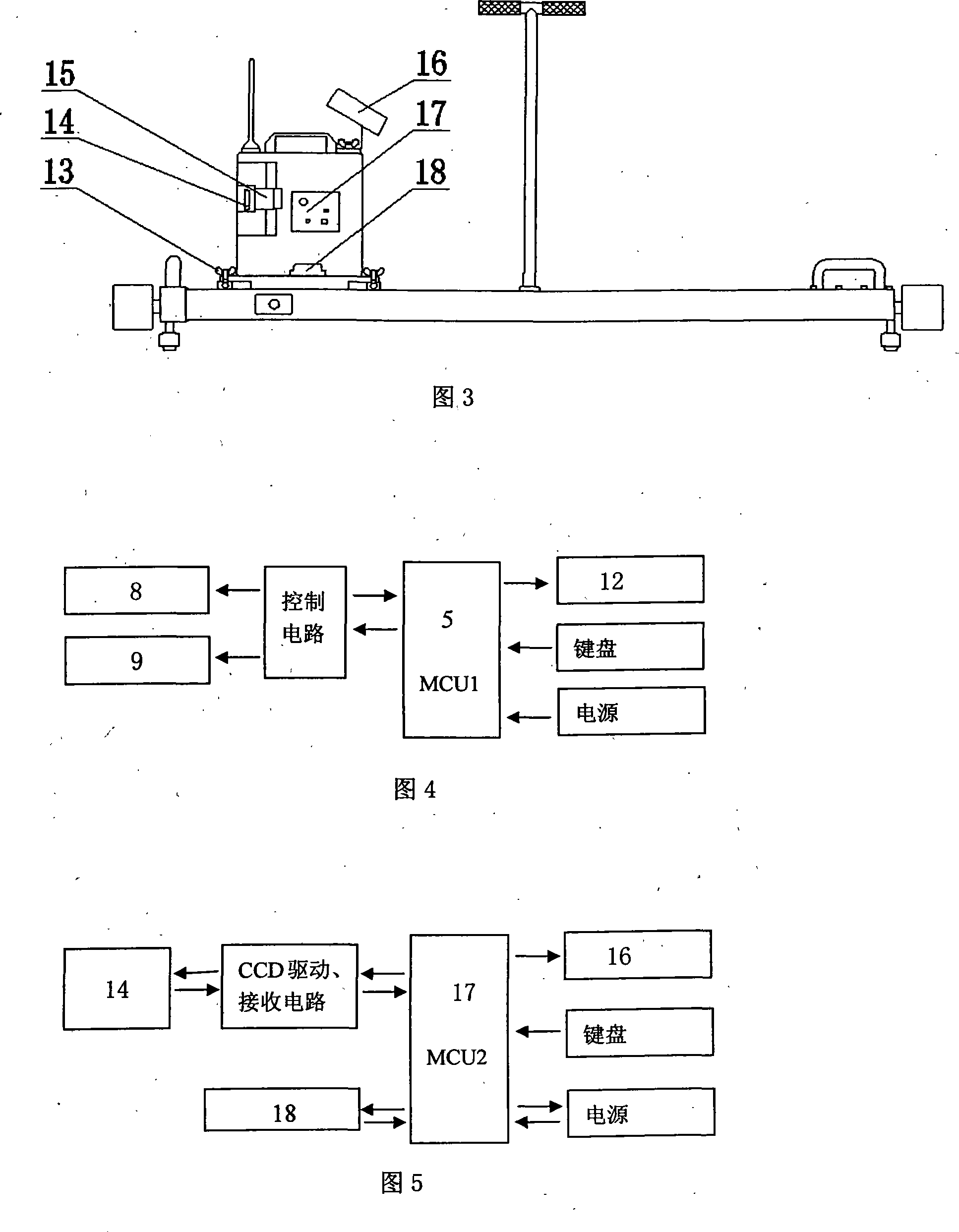

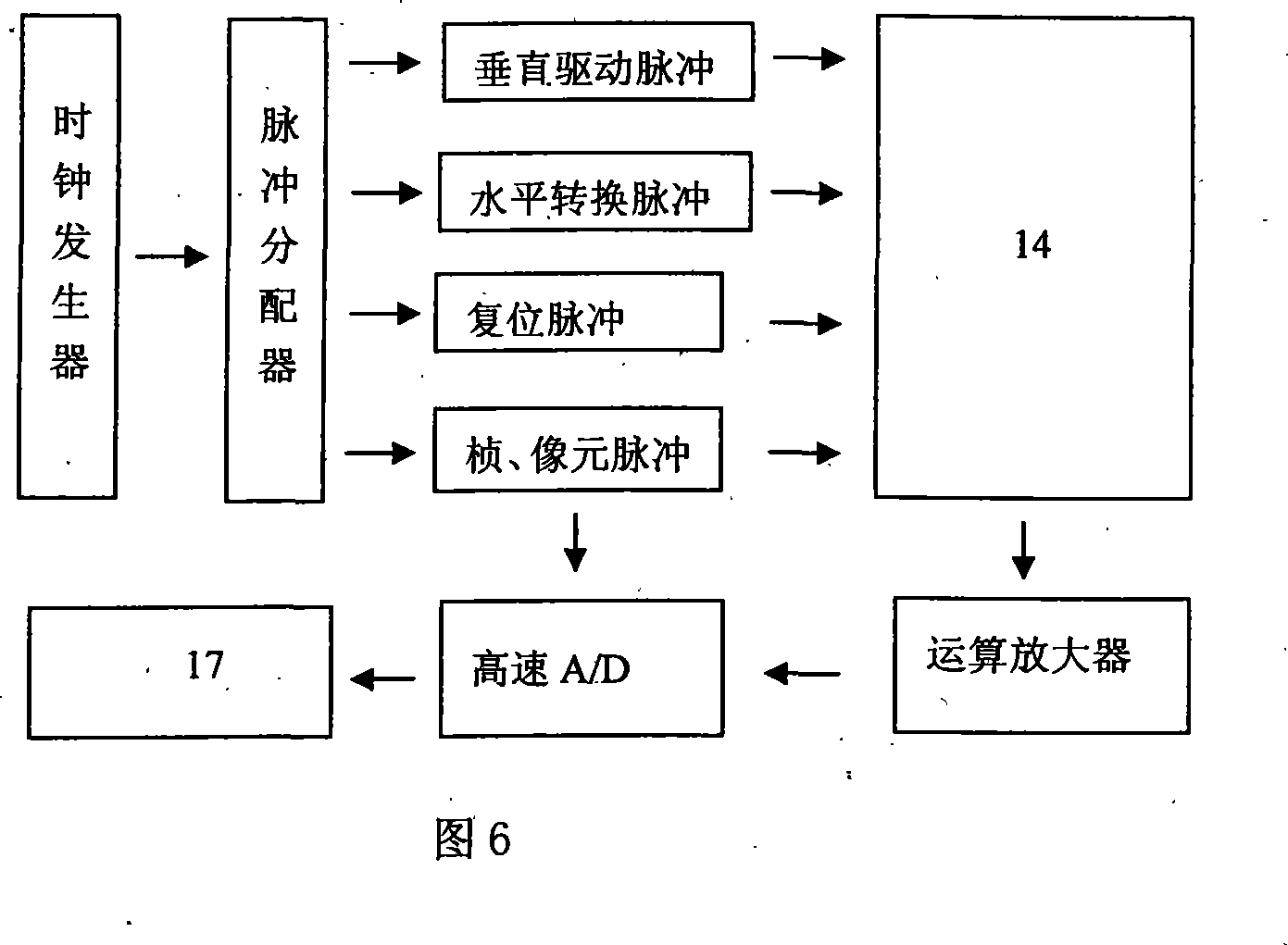

[0020] The laser measuring instrument for starting and setting railway tracks of the present invention includes a laser emitting device, a measuring device and a traveling trolley, and the laser emitting device and the measuring device are respectively installed on a traveling trolley. A wireless communication device is installed on the laser emitting device and the measuring device, and the two communicate through wireless. The walking trolley is made up of side wheels 1, walking wheels 2, push rod 10 and vehicle frame 11 (see Fig. 1). Wheel 1 is in contact with the side of the rail, and push rod 10 is installed on the vehicle frame 11 and can be disassembled when not in use. A handle 12 is installed on the vehicle frame 11, and the operator holds the handle 12 to make the walking trolley go up and down the road conveniently.

[0021] As shown in Figure 1, the laser emitting device is fixed on the walking trolley through the fastening knob 3. The laser emitting device includ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com