Corona discharge plasma reactor used for treating vehicle exhaust

A corona discharge and plasma technology, applied in exhaust devices, separation methods, dispersed particle separation, etc., can solve the problems of low energy utilization rate, uneven spatial distribution of plasma, and the need for catalyst synergy, achieving structural The effect of parameter change, easy structure parameter and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

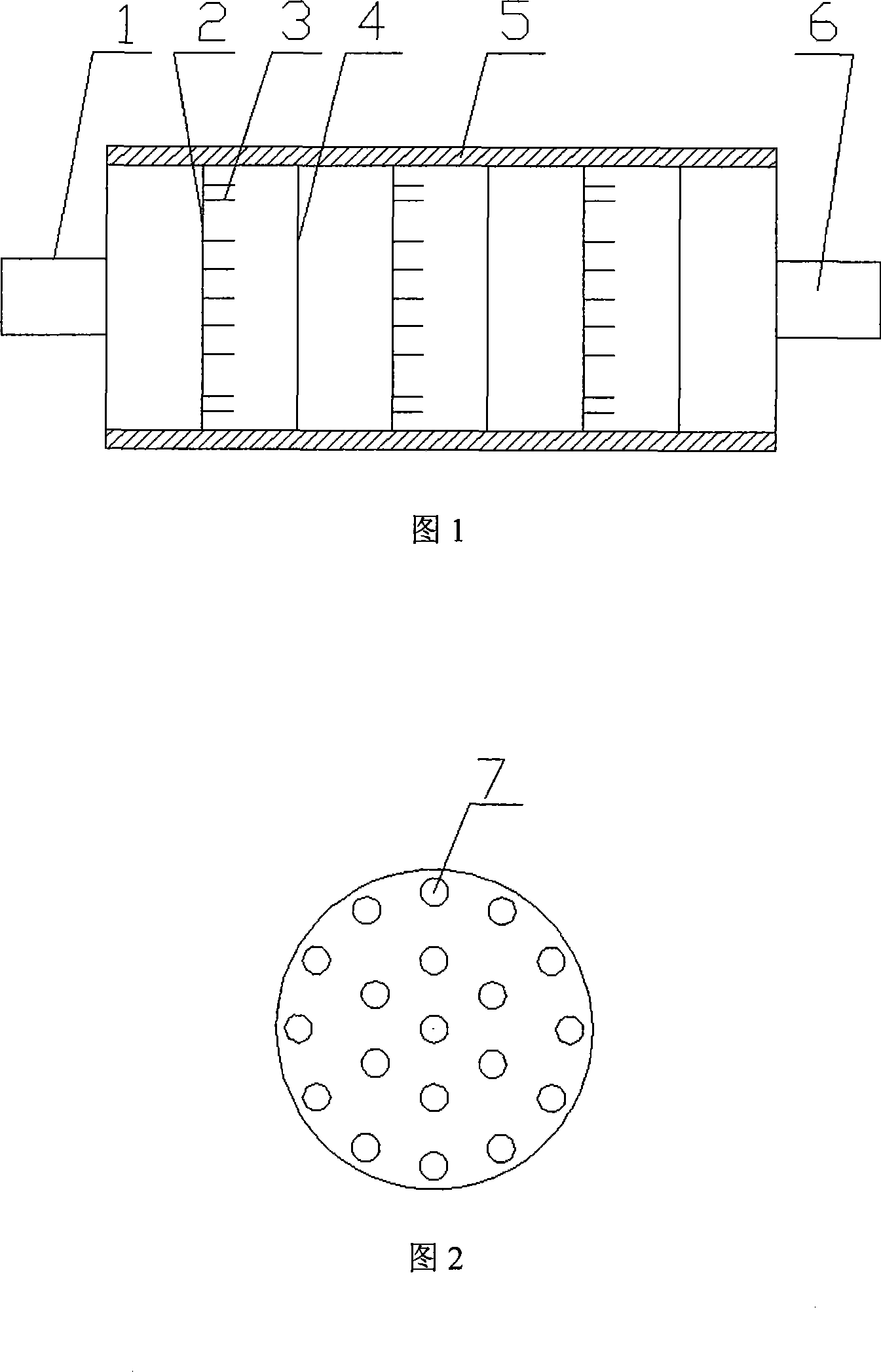

[0012] As shown in Figure 1, the plasma reactor consists of an insulating shell 5 and three sets of electrodes connected in series. Each group of electrodes is arranged in a needle-hole structure, and the multi-needle electrode is a discharge electrode, which is composed of a circular multi-needle electrode plate 2 and a stainless steel needle 3; the circular porous electrode 4 is a grounding electrode. Among them, the circular multi-needle electrode plate 2 has a diameter of 70mm, and 19 stainless steel needles 3 with a length of 8mm are evenly distributed on it, and the needle diameter is 0.8mm; The holes 7 are evenly distributed on it. When assembling, the needles 3 are all opposite to the center of the hole 7, and the distance between the pinholes is 21mm. The actual vehicle exhaust is produced under the condition of normal constant speed operation of the gasoline engine model HONDA EC2500L. When working, the exhaust gas of the automobile is passed into the reactor throu...

Embodiment 2

[0014] As shown in Figure 1, the plasma reactor consists of an insulating shell 5 and three sets of electrodes connected in series. Each group of electrodes is arranged in a needle-hole structure, and the multi-needle electrode is a discharge electrode, which is composed of a circular multi-needle electrode plate 2 and a stainless steel needle 3; the circular porous electrode 4 is a grounding electrode. Among them, the circular multi-needle electrode plate 2 has a diameter of 70 mm, and 19 stainless steel needles 3 with a length of 8 mm are evenly distributed on it, and the diameter of the needles is 0.6 mm; The holes 7 are evenly distributed on it. When assembling, the needles 3 are all opposite to the center of the hole 7, and the distance between the pinholes is 17mm. The actual vehicle exhaust is produced under the condition of normal constant speed operation of the gasoline engine model HONDA EC2500L. When working, the exhaust gas of the automobile is passed into the re...

Embodiment 3

[0016] A plasma reactor consisting of an insulating shell and two sets of electrodes connected in series is used to treat automobile exhaust, and other experimental conditions are the same as in Example 1. The experimental results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com