A process for the preparation of substituted phenyl ether compounds and rosiglitazone

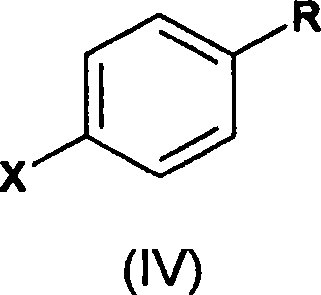

A compound, phenyl technology, applied in the field of acid addition salts, key intermediates of thiazolidinedione derivatives, and pyridyl-substituted ethoxybenzaldehyde, which can solve problems such as low yields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] Preparation of 2-(N-methyl-N-(2-pyridyl)amino)ethanol

[0062] A mixture of 1.5 kg (13.21 mol) of 2-chloropyridine and 12.75 l (158.7 mol) of 2-(N-methylamino)ethanol was stirred at 120-125° C. for about 22 hours. Excess 2-(N-methylamino)ethanol (approximately 9.1 l) was then distilled off under reduced pressure. To the oily residue was added 3.0 1 of water at 25-35°C and the solution was stirred for 30 minutes, then 3.0 1 of toluene was added and stirred for 30 minutes. The aqueous layer was separated and extracted twice with 3.0 1 toluene. The combined organic layers were washed twice with 1.5 l of water. The organic solvent was evaporated under reduced pressure at 50-55°C. 1.82 kg (90.55%) of the title compound were obtained as an oil.

Embodiment 2

[0064] Preparation of 4-[2-(N-methyl-N-(2-pyridyl)amino)ethoxy]benzaldehyde

[0065] 450ml of toluene, 300ml of water, 91g of potassium hydroxide, 50g of 2-(N-ethyl-N-(2-pyridyl)amino)ethanol, 60g of 4-fluorobenzaldehyde and 56g of tetra-n-butylammonium bisulfate in 49- Heat at 52°C and stir vigorously at the same temperature for about 20 hours. 300ml of water was added to the reaction and stirred for 10-15 minutes and the aqueous layer was separated. The organic layer was washed with 300ml of water. The combined aqueous layers were extracted with 200ml of toluene and the layers were separated. The combined toluene layers were extracted with a mixture of 600 ml of water and 40 ml of concentrated hydrochloric acid. The aqueous extract was separated and 80 ml of 12% aqueous ammonium hydroxide were added with stirring. The precipitated product was isolated by filtration, washed with water and dried in vacuo to give 60.2 g of the title compound as a light yellow solid.

[006...

Embodiment 3

[0073] Preparation of 5-[4-[2-[N-methyl-N-(2-pyridyl)amino)ethoxy]benzylidene]thiazolidine-2,4-dione

[0074] Add 12.0l of toluene, 2.0kg (7.8mol) of 4-[2-(N-methyl-N-(2-pyridyl)amino)ethoxy]benzaldehyde and 1.0g (8.78mol) at 25-30°C ) in the mixture of 2,4-thiazolidinedione was added 14.4g piperidine and 10g acetic acid. The water was removed azeotropically by using a Dean Stark apparatus. The reaction mixture was heated at reflux temperature for 5 hours and the resulting orange reaction was cooled to 25-30°C. The solid separated was filtered and washed with 5.0 1 methanol. The obtained solid was dried under reduced pressure at 68-72° C. for 12 hours to obtain 2.16 g (75.8%) of the title compound.

[0075] Example 3(a)

[0076] Purification of 5-[4-[2-[N-methyl-N-(2-pyridyl)amino)ethoxy]benzylidene]thiazolidine-2,4-dione

[0077] 2.1kg 5-[4-[2-[N-methyl-N-(2-pyridyl) amino) ethoxy] benzylidene] thiazolidine-2,4-dione (obtained in Example 3 ) was dissolved in 9.0 l of N,N...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com