Reamer comprising a cutting plate

A reamer and plate cutting technology, which is applied in the direction of reamers, forming knives, metal processing equipment, etc., can solve the problems of high friction coefficient factor, heat generation, and lower surface quality, so as to improve the drilling surface, increase the service life of tools, The effect of increasing the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

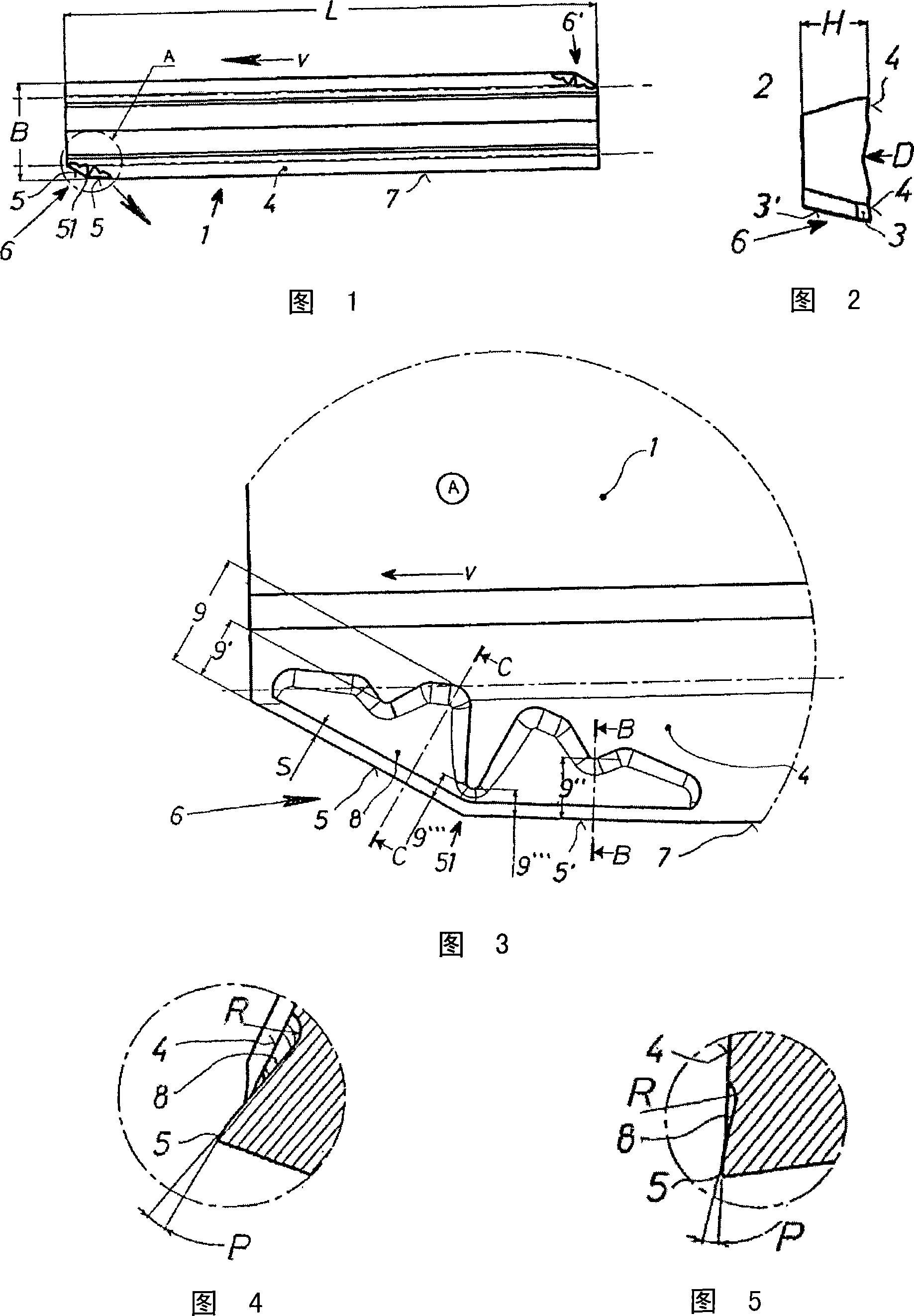

[0026] A plan view and a cross-sectional view of an indexable insert for reamer insertion are shown in FIGS. 1 and 2 . The indexable insert 1 has, for example, a length L of 16.5 mm, a width B of 3.6 mm and a thickness H of 2 mm, and has cutouts 6, 6' at opposite corners. A main cutting edge consisting of two cutting edge parts 5, 5' having a transition portion 51 can be formed in the cut-off 6. The secondary cutting edge 7 is formed in a direction opposite to the shown reamer feed direction V, or in the continuation of the primary cutting edge 5, 5'.

[0027] FIG. 2 shows an indexable plunger 1 in a sectional view, which has a bearing surface 2 for the insertion of the reamer in the working area. The tool flanks 3, 3' and the chip-carrying surface 4 form the main cutting edge 5, 5' and the secondary cutting edge 7, respectively.

[0028] The cutting section 6 of the cutting board 1 is shown in FIG. 3 . The cut-off portion 6 has a main cutting edge 5 at a relatively la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com