Spring lamination pair for microminiaturization voice coil motor

A technology of spring leaf and voice coil, applied in the field of spring leaf, can solve the problems of difficulty in ensuring the actual production quality, low assembly process cost, and large number of parts, so as to improve the displacement distance and response speed, reduce the number and The effect of processing technology and saving processing materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

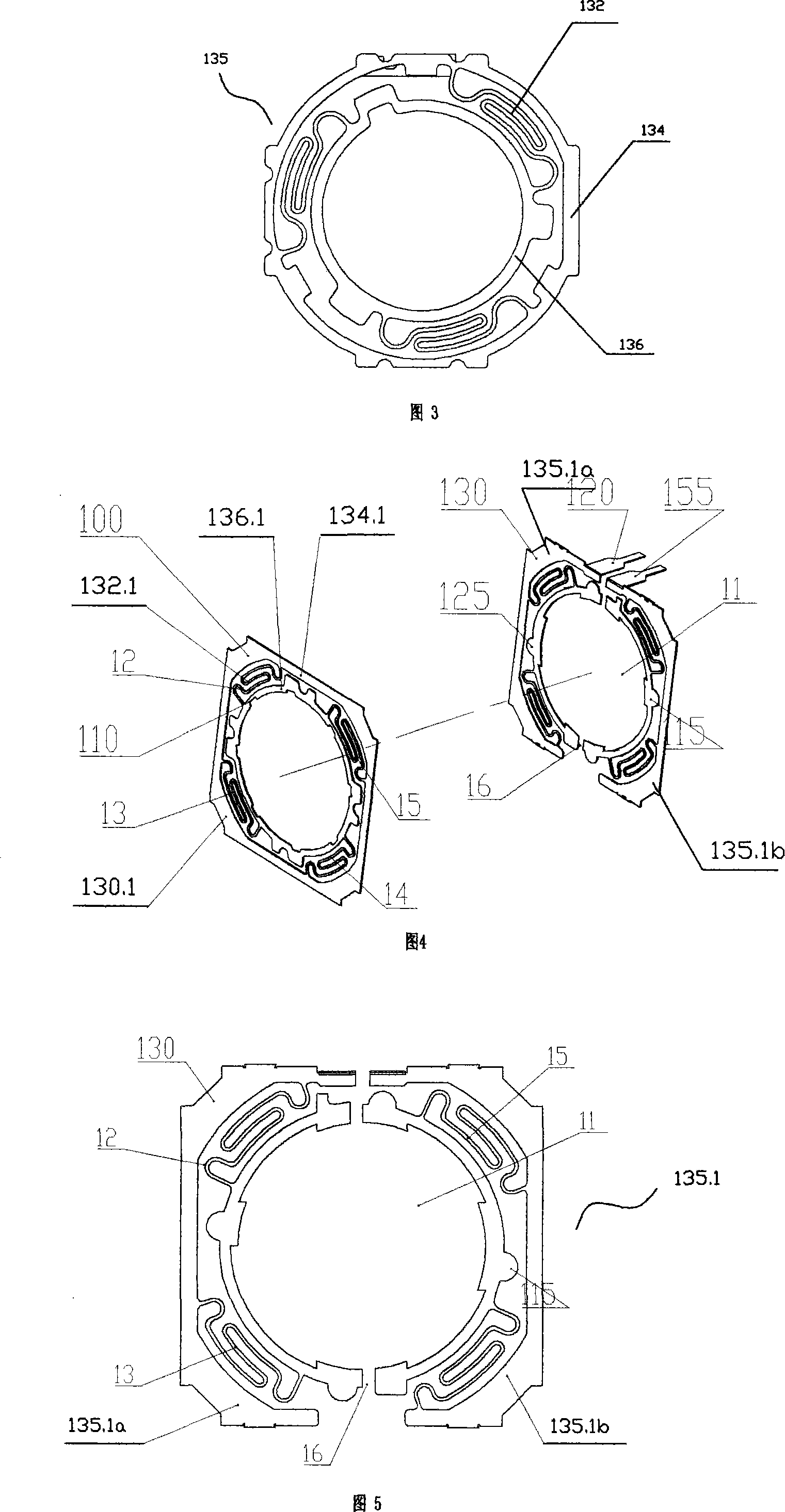

[0039]As shown in Fig. 4 and Fig. 5, the utility model includes: a front spring sheet 130.1 and a rear spring sheet 135.1, and the front spring sheet 130.1 and the rear spring sheet 135.1 all include a flat substrate 10, and the substrate can be a copper-tin-nickel alloy It is made of sheet, which has excellent elasticity, fatigue resistance, electrical conductivity, easy welding, and oxidation resistance. There is a center hole 11 in the center of the base body, and the outer periphery of the center hole 11 is coaxially distributed with an inner ring moving ring 136.1 and an outer ring fixing ring 134.1 radially from the inside to the outside. The inner ring moving ring 134.1 is provided with at least one clip position structure 20, the inner ring moving ring 136.1 can rely on the concave-convex locking structure 20 and the moving seat 120 to achieve radial positioning, and rely on the pressing of the front and rear brackets 100, 105 to achieve axial positioning; the outer rin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com