Vertical shaft hanging scaffold stabilizing device

A hanging plate and shaft technology, which is applied to shaft equipment, shaft lining, transportation and packaging, etc., can solve the problems of unreliable safety performance, low reuse rate, harm to construction personnel, etc., saving money, manpower, and processing. effect of material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

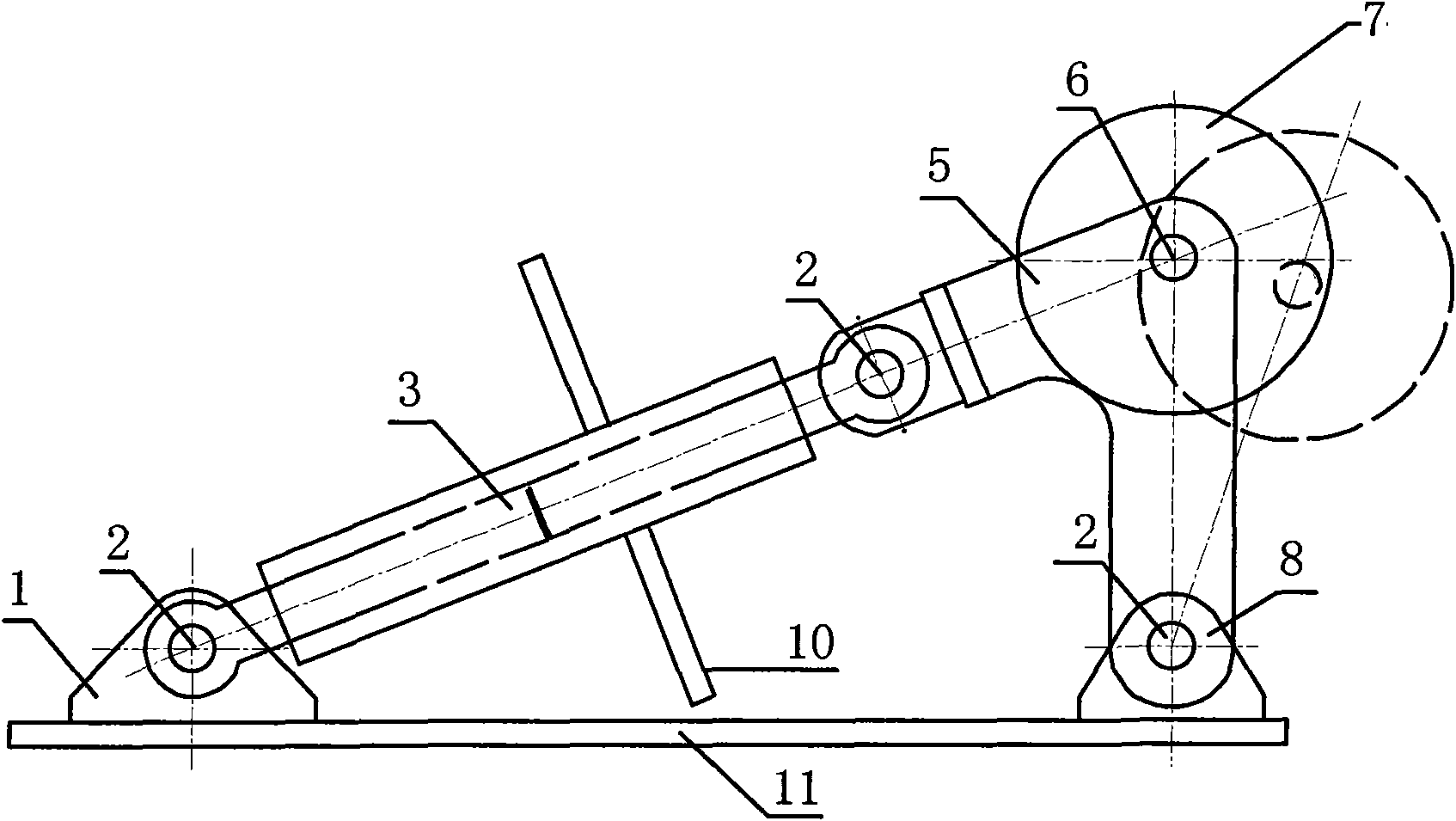

[0013] Embodiment 1: this plate stabilizing device comprises base plate 11, bearing, connecting rod 5, adjuster 3, rubber wheel 7, two bearings are arranged on base plate, and connecting rod 5 is connected on a bearing, between connecting rod and A regulator 3 is connected between the other supports, and a rubber wheel 7 is also connected on the connecting rod.

[0014] Described two bearings, one is regulator bearing 1, and one is connecting rod bearing 8.

[0015] The regulator has a screw barrel, each of which is connected with a screw rod at two ends of the screw barrel, and the threads of the two screw rods are reversed, and a rotary handle 10 is arranged outside the screw barrel.

[0016] The connecting rod is bent, and the two ends of the connecting rod 5 are respectively connected with the connecting rod support 8 and the adjuster, and a rubber wheel 7 is connected at the middle position of the connecting rod 5 .

[0017] The adjuster 3 is connected with the adjuster ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com