Method for manufacturing cuprum-cover-silver as well as silver alloy three composite rivet contact

A three-composite, silver alloy technology, used in electrical components, electrical switches, circuits, etc., can solve the problems of easy solder flow, low yield, low artificial welding efficiency, etc., to improve bonding strength, production efficiency and material utilization. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

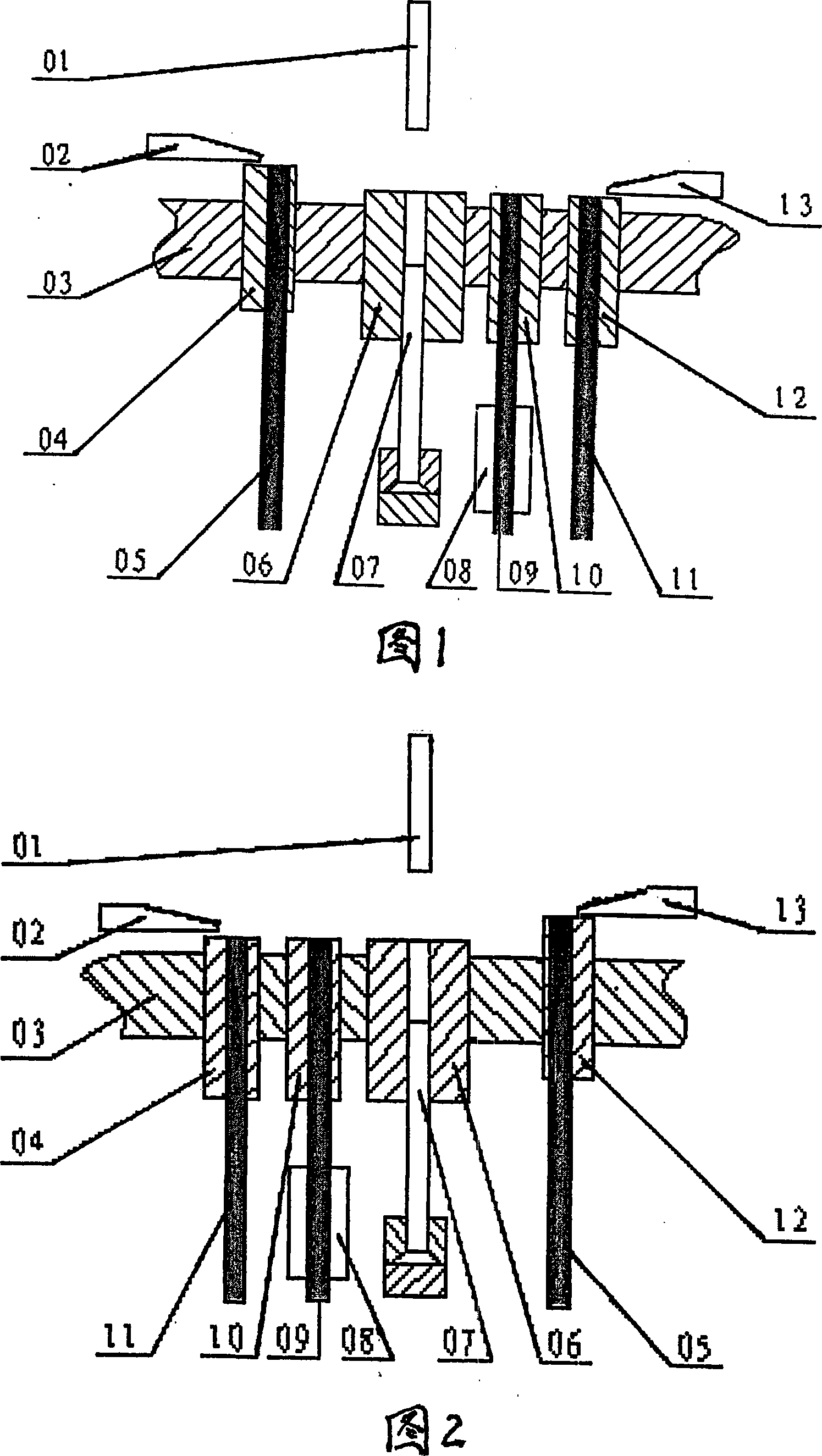

[0012] See Figure 1. After the right cutter 13 cuts the copper material 11 to a length of 3.2 mm, it moves to the position of the silver wire 09. The silver wire 09 is sent to the right cutter 13 through the newly added wire feeding device 08 to cut the length of 1.5 mm. The silver wire 05 The left cutter 02 is fed into the cutting length of 1.8mm through the newly added wire feeding device 08, the left cutter 02 and the right cutter 13 move to the center of the bottom mold 06 and stop at the same time, and the first mold needle 01 cuts the two knives. The three-stage material is pushed into the bottom mold 06 hole, and is upset and deformed in the bottom mold 06 hole. The left cutter 02, the right cutter 13 and the head mold needle 01 are reset to the initial position, and the bottom mold needle 07 will be covered. The good three-composite material rod is sent to the front end of the bottom mold, that is, the required position of the contact foot, and the part of the material ...

Embodiment 2

[0014] See Figure 1. After the right cutter 13 cuts the copper material 11 to a length of 3.2 mm, it moves to the position of the silver wire 09. The silver wire 09 is sent to the right cutter 13 through the newly added wire feeding device 08 to cut the length of 1.5 mm. The silver wire 05 The left cutter 02 is fed into the cutting length of 1.8mm through the newly added wire feeding device 08, the left cutter 02 and the right cutter 13 move to the center of the bottom mold 06 and stop at the same time, and the first mold needle 01 cuts the two knives. The three-stage material is pushed into the bottom mold 06 hole, and is upset and deformed in the bottom mold 06 hole. The left cutter 02, the right cutter 13 and the head mold needle 01 are reset to the initial position, and the bottom mold needle 07 will be covered. The good three-composite material rod is sent to the front end of the bottom mold, that is, the required position of the contact foot, and the part of the material ...

Embodiment 3

[0016] See Figure 1. After the right cutter 13 cuts the copper material 11 to a length of 2.1 mm, it moves to the position of the silver wire 09. The silver wire 09 is sent to the right cutter 13 through the newly added wire feeding device 08 to cut the length of 0.83 mm. The silver wire 05 The left cutter 02 is sent to the cutting length of 1.2mm through the newly added wire feeding device 08, the left cutter 02 and the right cutter 13 move to the center of the bottom mold 06 and stop at the same time, and the first mold needle 01 cuts the two knives. The three-stage material is pushed into the bottom mold 06 hole, and is upset and deformed in the bottom mold 06 hole. The left cutter 02, the right cutter 13 and the head mold needle 01 are reset to the initial position, and the bottom mold needle 07 will be covered. The good three-composite material rod is sent to the front end of the bottom mold, that is, the required position of the contact foot, and the part of the material ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com