Precision plastic rubber shaping multi-machine control system

A control system and precision molding technology, applied in transmission systems, comprehensive factory control, electrical program control, etc., can solve problems such as hindering modern production methods, waste of resources, and low level of automation, and achieve high engineering value and economic significance. Complexity and cost, effects of improved management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

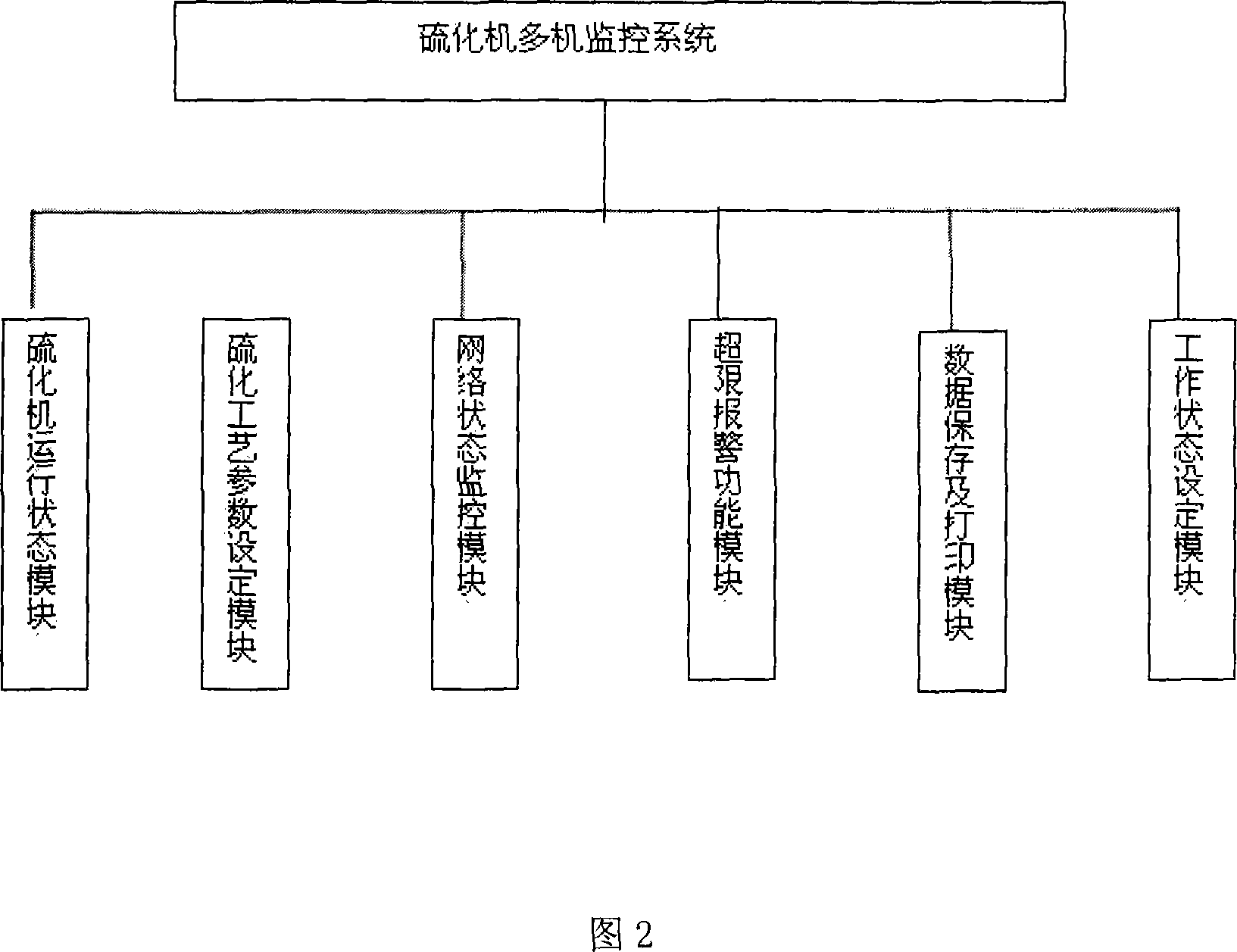

[0012] The monitoring host computer of this system adopts high-performance industrial control computer, selects Advantech IPC-610, and connects with the Ethernet ring network through the German Hilscher cifX50 Ethernet card to realize the communication with the controlled system. It mainly realizes the display, storage, printing, alarm and other functions of the collected data on site, and completes the monitoring of the operation status of the entire plastic molding machine group and the setting of process parameters. The backbone ring network of the system adopts industrial 100M shielded twisted pair to increase the belt speed and ensure the real-time communication. Three TSC Carat50 series industrial Ethernet switches supporting redundant ring network topology are used.

[0013] The system selects 6 groups of Siemens PLC S7-200 and CP 243-1 industrial Ethernet modules to control 6 vulcanizing machines on site respectively. CP 243-1 communication module connects PLC S7-200 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com