High pressure temperature on-line monitoring photoelectricity inversion thimble structure

A photoelectric converter and high-voltage technology, applied in radiation pyrometry, electric radiation detectors, measuring devices, etc., can solve the problems of affecting power supply of other circuits, not allowing long-term power outages, etc., and achieve equipment condition maintenance and distribution Power grid automation, convenient equipment condition maintenance and distribution network automation, the effect of safe use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

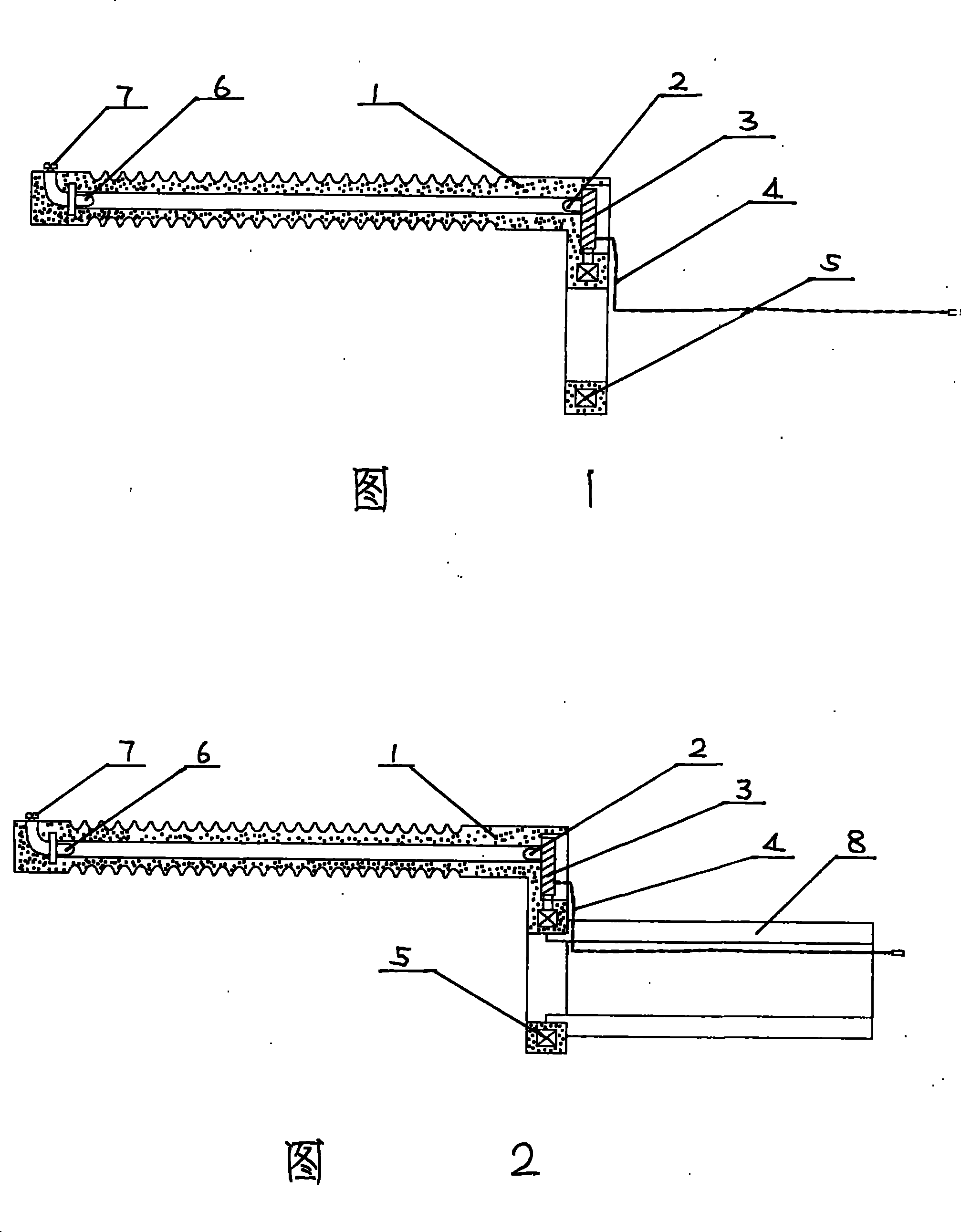

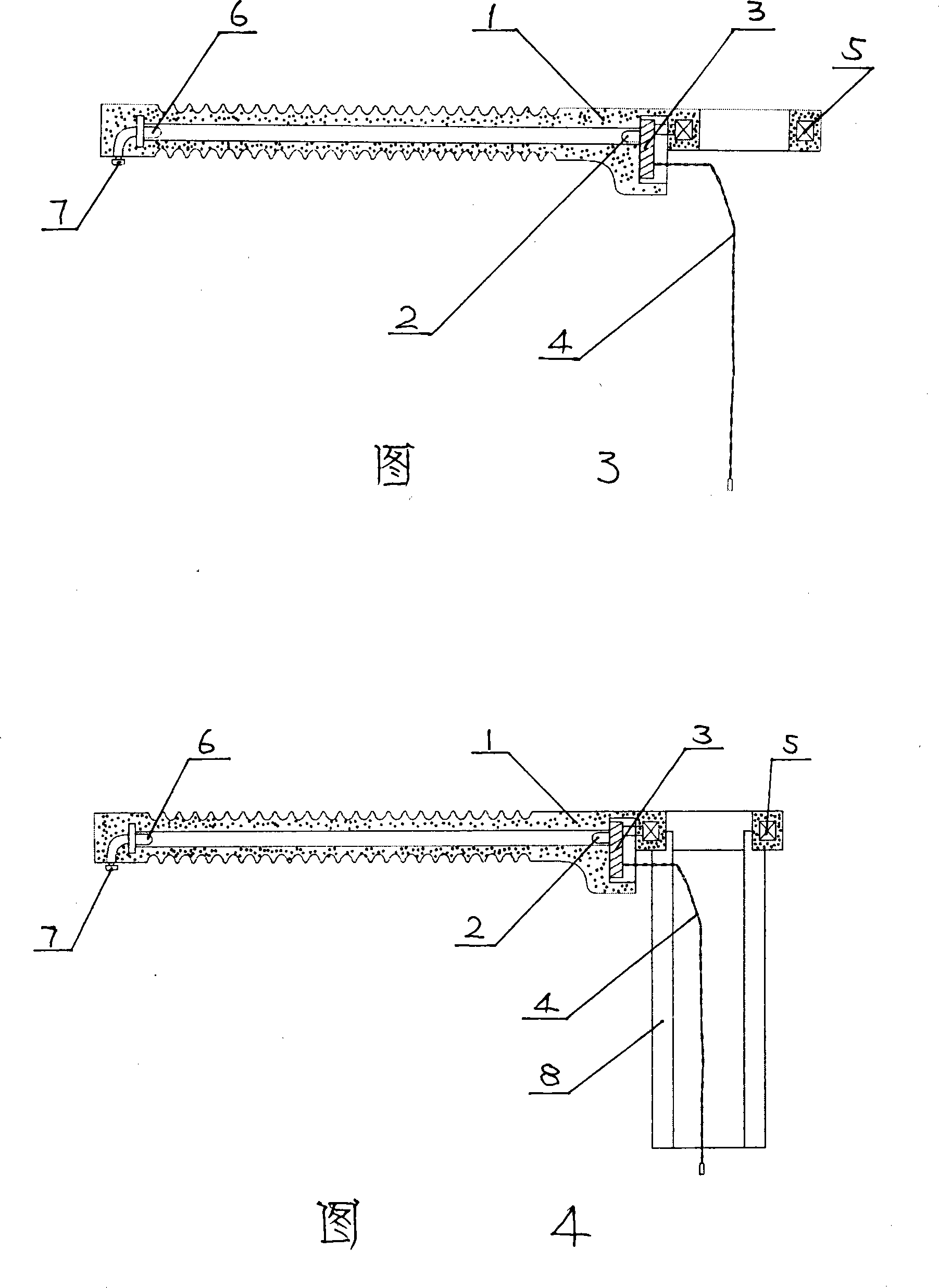

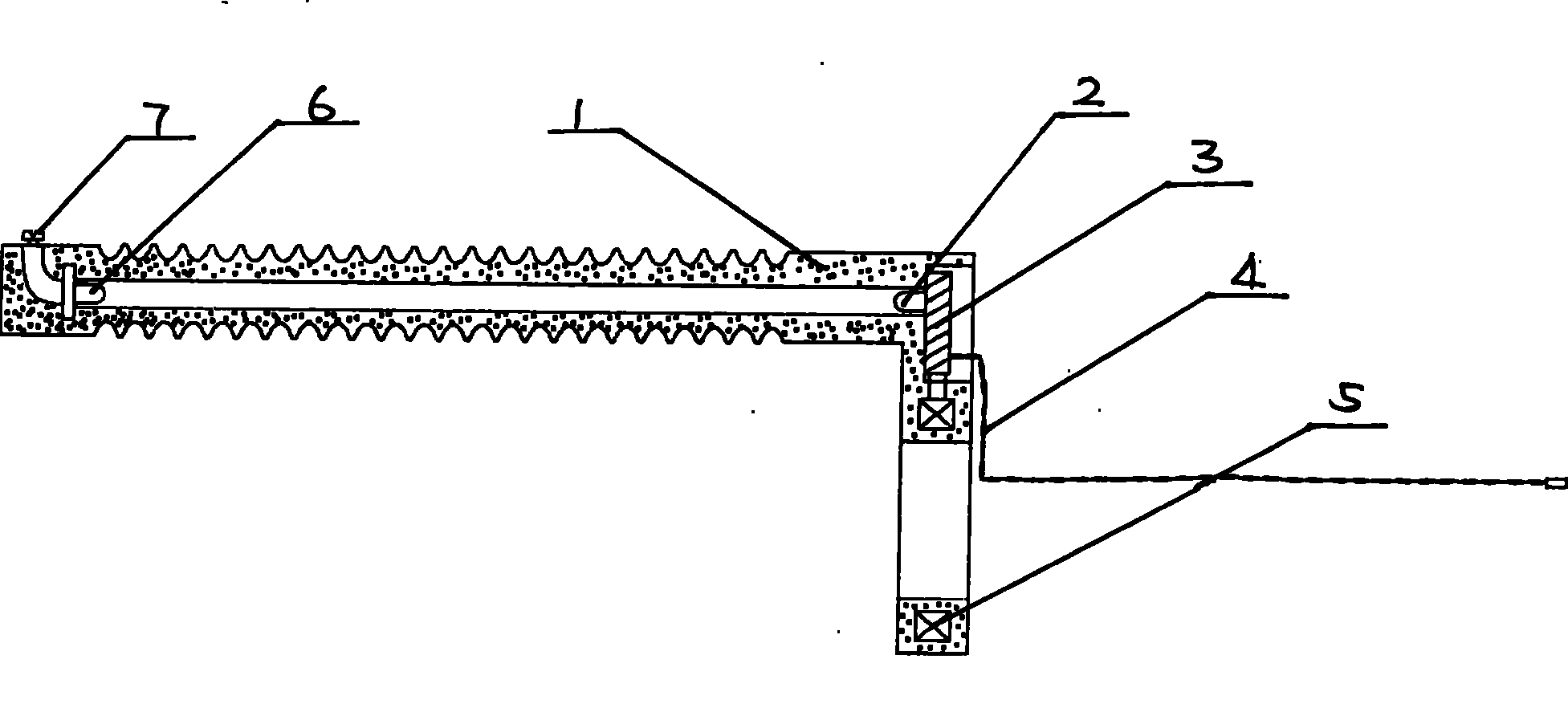

[0019] Please refer to Fig. 1, there is a collar main body 1, and a circular collar is arranged on the front end of the collar main body 1, and an inductive power supply 5 is embedded inside the collar; the upper end of the collar main body 1 is provided with a photoelectric transducer 3; The other end connected with the lead wire is connected with the induction power supply 5; the photoelectric transducer 3 is connected with a thermal detector 4, and the thermal detector 4 touches the external temperature detection part; the inner end of the photoelectric transducer 3 is connected with the infrared emission tube 2, and the infrared emission The tube 2 corresponds to a transparent hole, and the other end of the hole is provided with an infrared receiving tube 6, and the other end of the infrared receiving tube 6 is connected to the signal output terminal 7; the terminal 7 is connected to the external control unit through a wire.

Embodiment 2

[0021] see figure 2 , there is a collar main body 1, a circular collar is arranged at the front end of the collar main body 1, a sleeve 8 is embedded in the circular collar, and an induction power supply 5 is embedded inside the collar; the upper end of the collar main body 1 is provided with a photoelectric conversion 3; the other end of the photoelectric transducer 3 connected with the lead wire is connected with the induction power supply 5; the photoelectric transducer 3 is connected with a thermal detector 4, and the thermal detector 4 touches with the external detection temperature position; the inner end of the photoelectric transducer 3 is connected with the infrared The transmitting tube 2 is connected, and the infrared transmitting tube 2 has a transparent hole correspondingly. The other end of the hole is provided with an infrared receiving tube 6, and the other end of the infrared receiving tube 6 is connected to the signal output terminal 7; the terminal 7 is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com