Multifunctional positively-agitating type asphalt pavement maintenance vehicle

A technology of asphalt pavement and forced mixer, which is applied in the direction of roads, roads, road repairs, etc. It can solve the problems of not being able to provide high-quality asphalt concrete, uneven mixing of asphalt and mineral materials, and affecting the compactness of asphalt concrete. Effect of dry quality, enhanced mixing quality, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

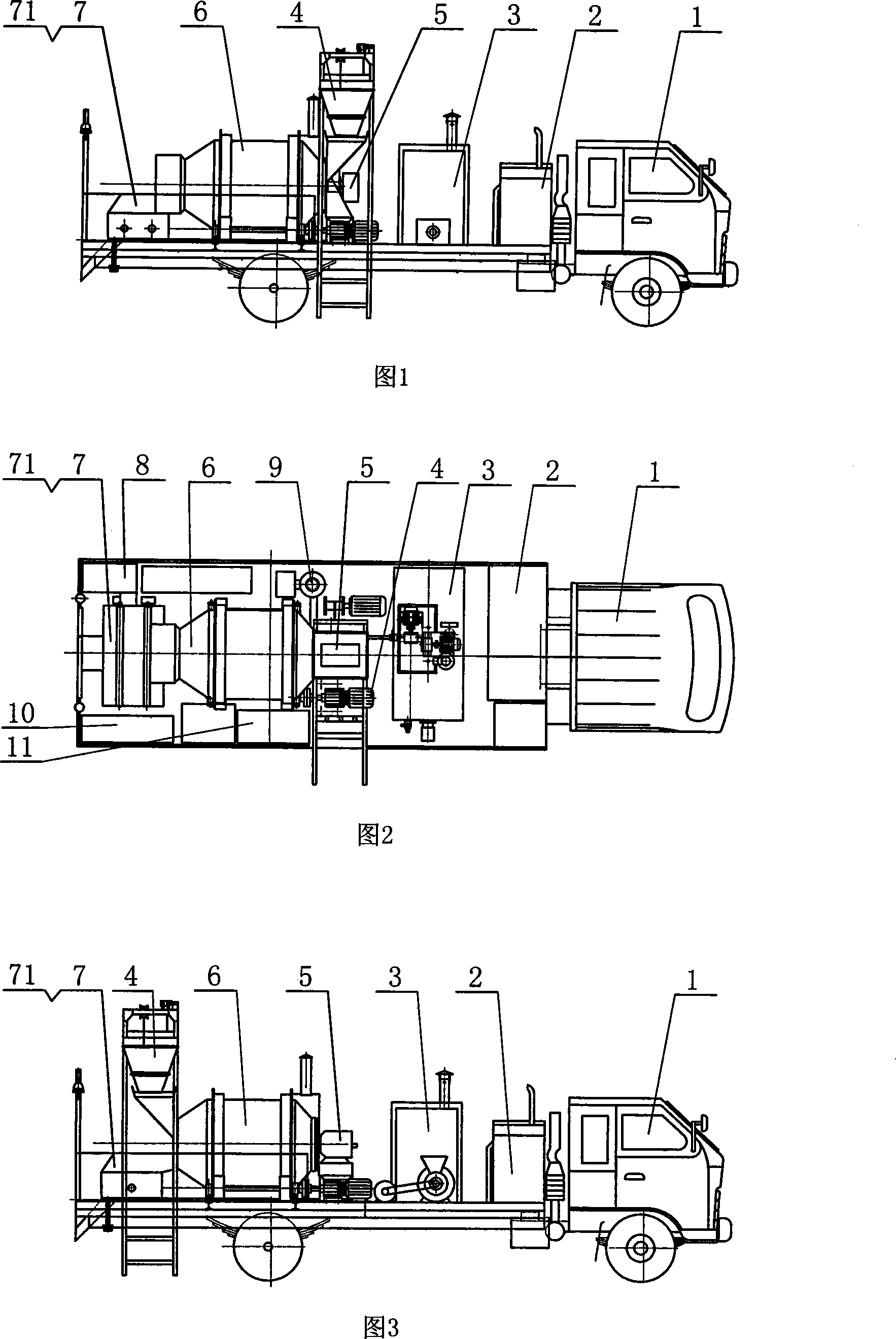

[0023] Referring to the accompanying drawings, a multifunctional forced-stirring asphalt pavement maintenance vehicle includes a generator set 2 arranged on the front of a chassis 1 of a car or a trailer, an asphalt tank and an asphalt metering supply device 3 arranged behind the generator set 2, and mineral material Lifting device 4, burner 5, mineral material drying and heating device 6, asphalt concrete forced mixing device 7, mineral powder weighing and conveying device 8, dust removal device 9, electric control device 10 and accessory device 11, mineral material lifting device 4 Connected to the front of the mineral material drying and heating device 6 or fixedly connected to the back of the mineral material drying and heating device 6, in order to overcome the blockage when the mineral material enters the drying cylinder of the mineral material drying and heating device 6 from the lifting hopper of the mineral material lifting device 4 The flame of the burner affects the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com