Method for utilizing thermal energy during continuous synthesis of glyphosate

A glyphosate and thermal energy technology, applied in chemical instruments and methods, preparation of organic compounds, preparation of hydroxyl compounds, etc., can solve the problems of low level of energy utilization, few researches on rational utilization of unstorable energy, etc., and reduce social energy. Shortage problem, saving effect of solvent recovery and consumption of steam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

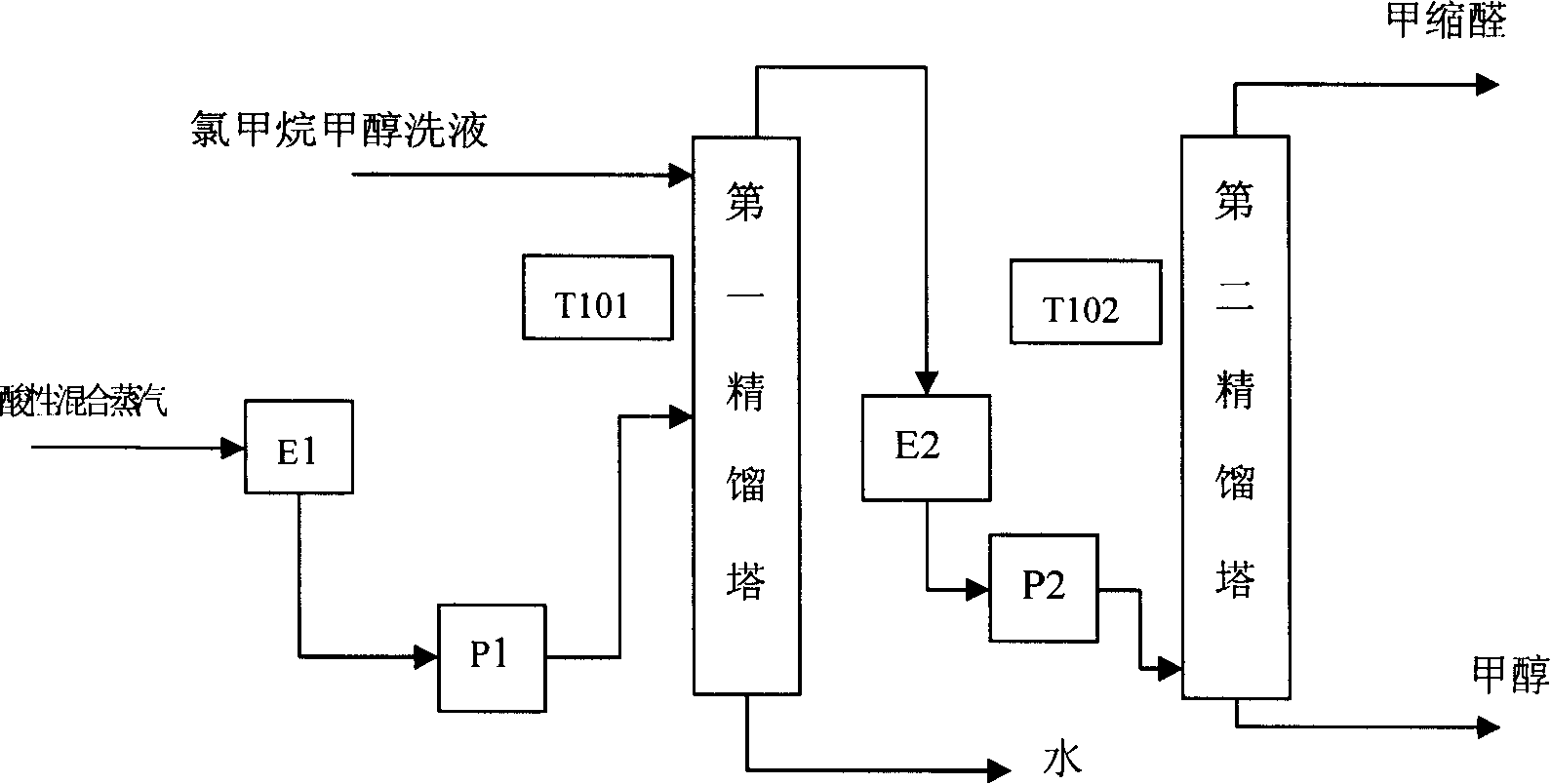

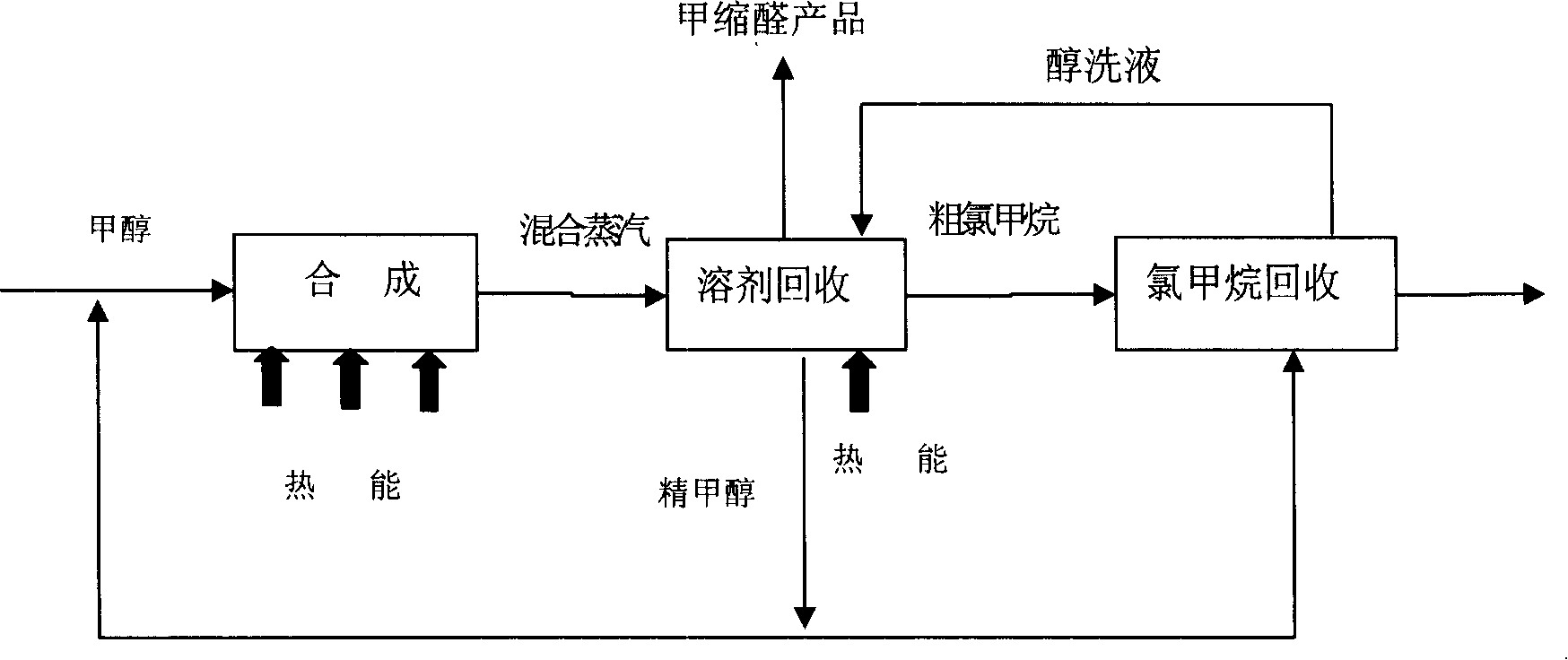

[0040]The mixed steam produced in the hydrolysis process is preheated to 103°C and then pressurized to 0.025MPa by the air compressor, and enters the tower from the middle and lower part of the tower. Sodium hydroxide methanol solution is fed from the top of the tower as the reflux liquid, the reflux ratio is controlled at 1:3, countercurrent contact, neutralization, the pH of the overhead distillate is adjusted at 6.5 to 7.0, and the pH of the tower still water is at 9 to 10. The overhead distillate is preheated and sent to the lower rectification tower to separate methylal and methanol, and the obtained methanol product content: ≥99%; methylal product content: ≥85%.

Embodiment 2

[0042] The mixed steam generated in the hydrolysis process is washed by the thermal insulation spray alkali washing tower, the gas from the top of the washing tower is preheated and pressurized by the air compressor into the dehydration tower, and the washing liquid enters the dehydration tower kettle, and the reflux ratio is controlled at 1:4 , The gas containing methylal and methanol is distilled from the top of the tower, and after preheating, it is sent to the lower rectification tower to separate methylal and methanol. The obtained methanol product content: ≥99%; the methylal product content: ≥85%.

Embodiment 3

[0044] The mixed steam produced in the hydrolysis process is preheated to 103°C and then pressurized to 0.025MPa by the air compressor, and enters the tower from the middle and lower part of the tower, and the methanol solution of sodium hydroxide is fed from the top of the tower, and the reflux ratio is controlled to 1 : 3, countercurrent contact, neutralization, adjust the pH of the overhead distillate at 6.5 to 7.0, the pH of the tower still water at 9 to 10, and the tower overhead is sent to the lower rectifying tower through preheating to separate formaldehyde Aldehyde and methanol, the obtained methanol product content: ≥99%; methylal product content: ≥85%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com