Low floor passenger-carrying chassis

A bus chassis and low-floor technology, which is applied to the upper structure of the bus, vehicle parts, upper structure, etc., can solve the problem of the height of the bus chassis, and achieve the effects of low center of gravity, good handling performance and convenient disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

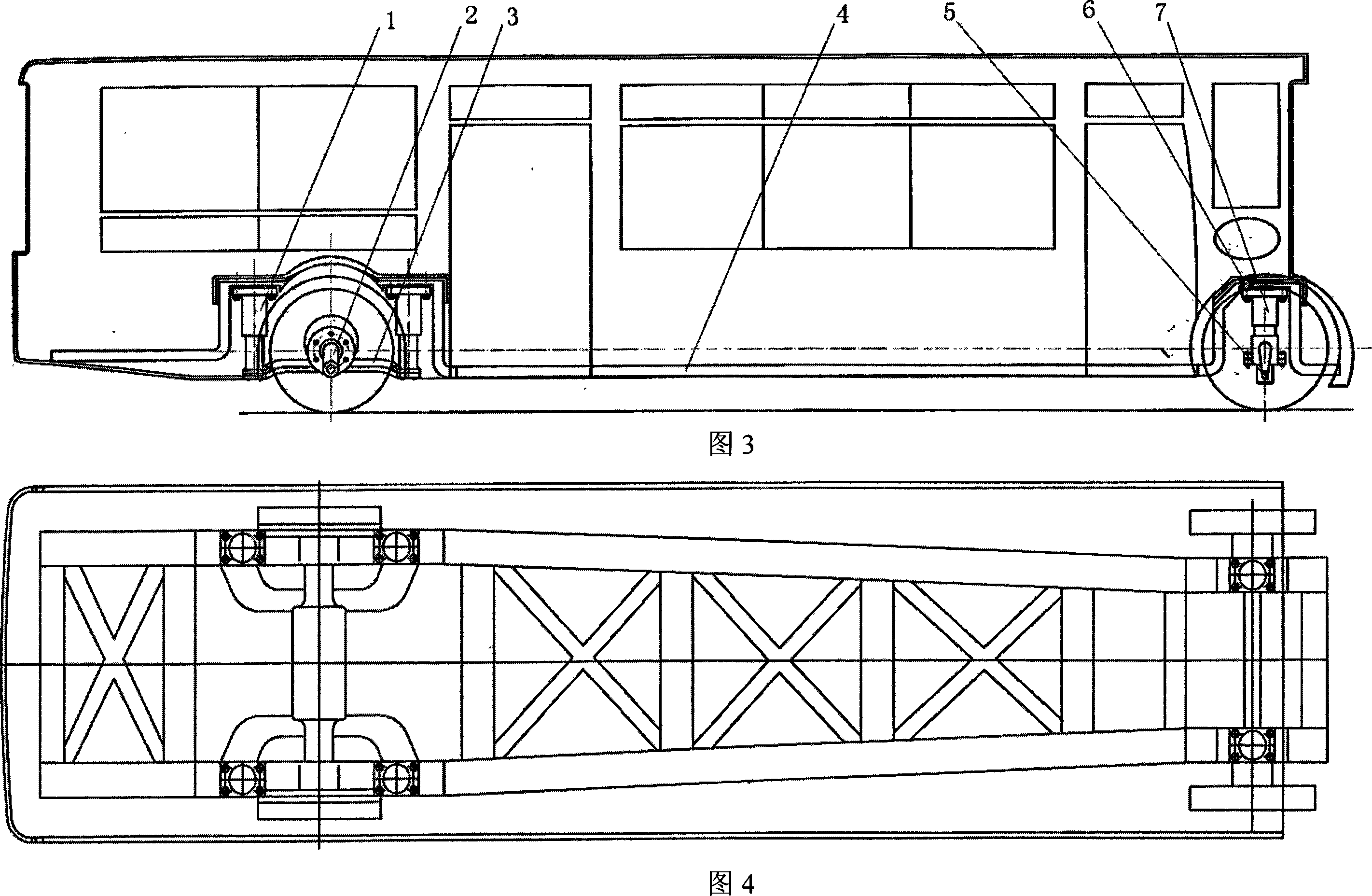

[0014] Hereinafter, specific implementations of the present invention are given with reference to FIGS. 3-4 to further illustrate the structure of the present invention.

[0015] The low-floor passenger car chassis of this embodiment includes longitudinal beams and transverse beams constituting the chassis frame 4, the transverse beams and the longitudinal beams are fixedly connected together to form a closed frame structure, and the transverse beams of the chassis frame 4 span the rear axle to absorb shock Suspension system 1. Above the front axle damping suspension system 7, is a full-bearing chassis frame. The lower end of the rear axle damping suspension system 1 is connected to the damping suspension system trailer 3, and the upper end is fixed with the cross beam of the chassis frame 4; The upper end of the bridge damping suspension system 7 is fixed to the cross beam of the chassis frame 4, and the lower end is connected to the front axle; the rear end of the front axle is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com