V type belt inducing hot pressure forming module

A technology for forming molds and molds, which is applied in belts, applications, household appliances, etc., can solve the problems of high heat loss, difficult control, and low dimensional accuracy of products, so as to reduce investment costs, improve comprehensive performance, and high dimensional accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

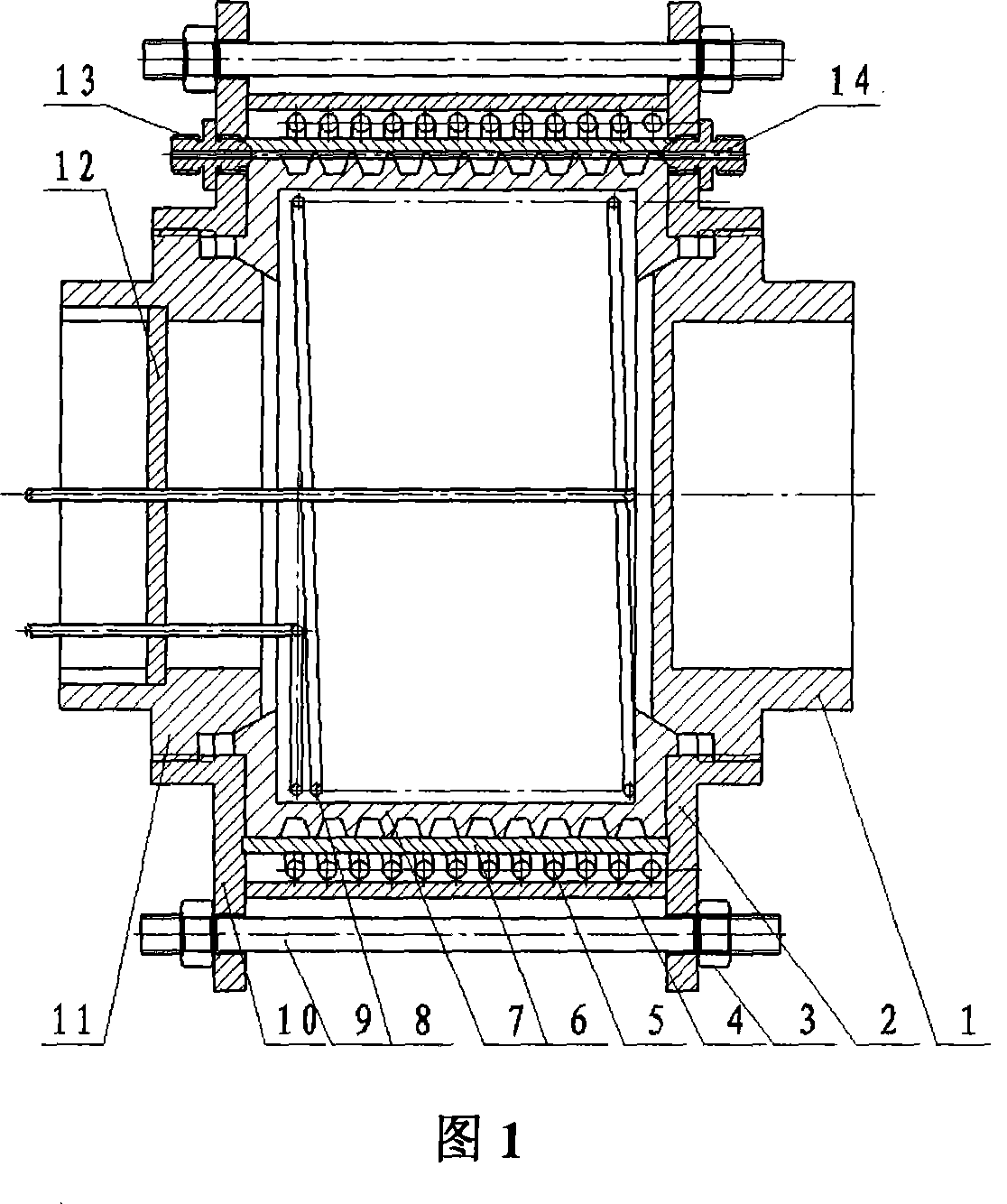

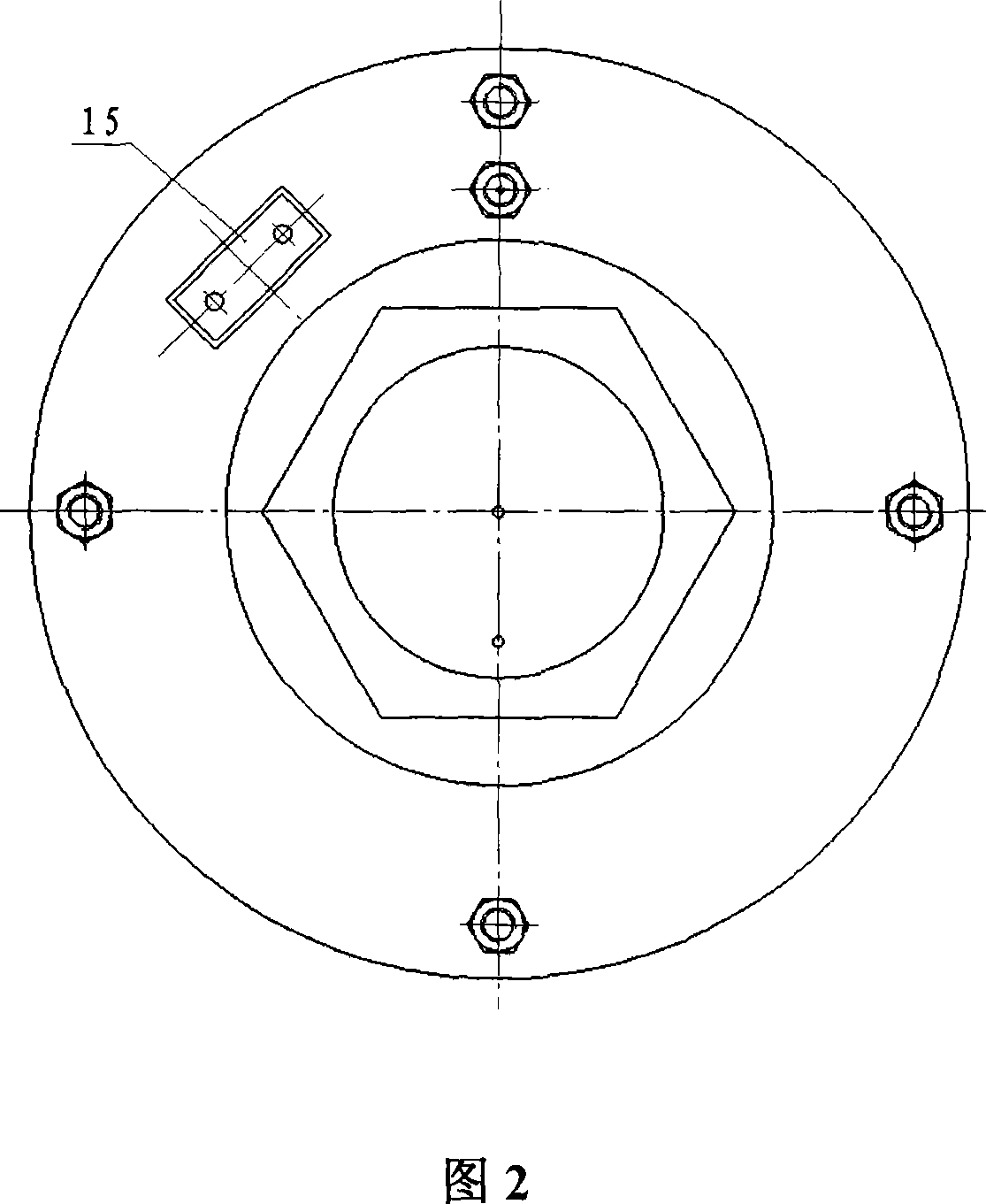

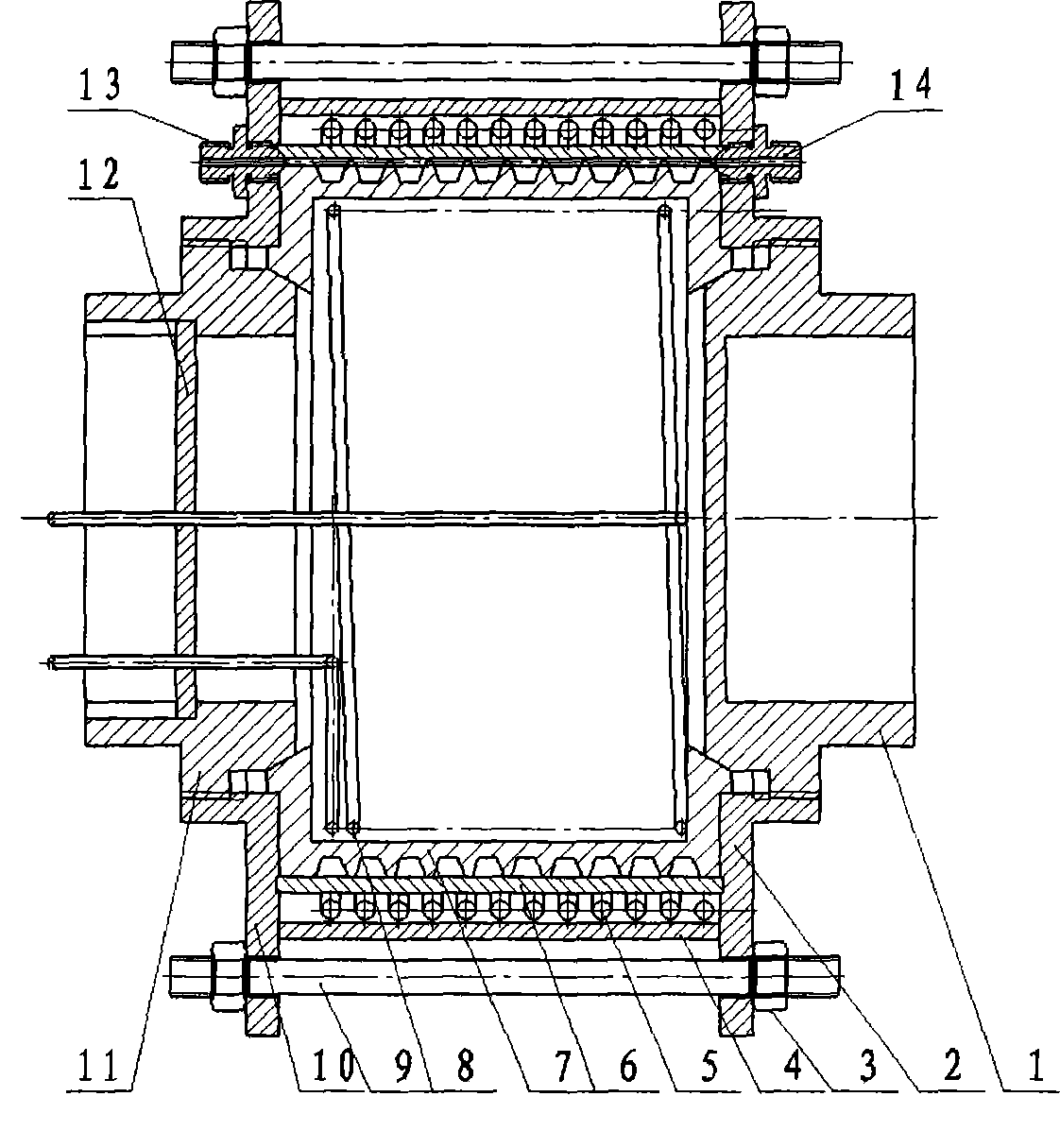

[0016] The technical solution of the V-shaped belt induction hot-pressing molding die involved in the present invention is: the device consists of a right end cover 1, a right head 2, a nut 3, an outer cover 4, an outer induction coil 5, an upper heating plate 6, and a combined film cavity 7. Inner induction coil 8, screw rod 9, left head 10, left end cover 11, cover plate 12, injection joint 13, exhaust joint 14, coil fixing plate 15 and other parts. The inner induction coil 8 is installed in the composite membrane chamber 7, and the composite membrane chamber 7 is positioned by the inner holes of the left end cap 11 and the right end cap 1, and the conical surfaces of the left end cap 10 and the right end cap 2 ensure an ideal shape. The outer induction coil 5 is installed between the upper hot plate 6 and the outer cover 4 . The device is tightened by four screw rods 9 through the left and right end caps. There is a clearance fit between the upper hot plate 6 and the combi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com