Sheets for drilling

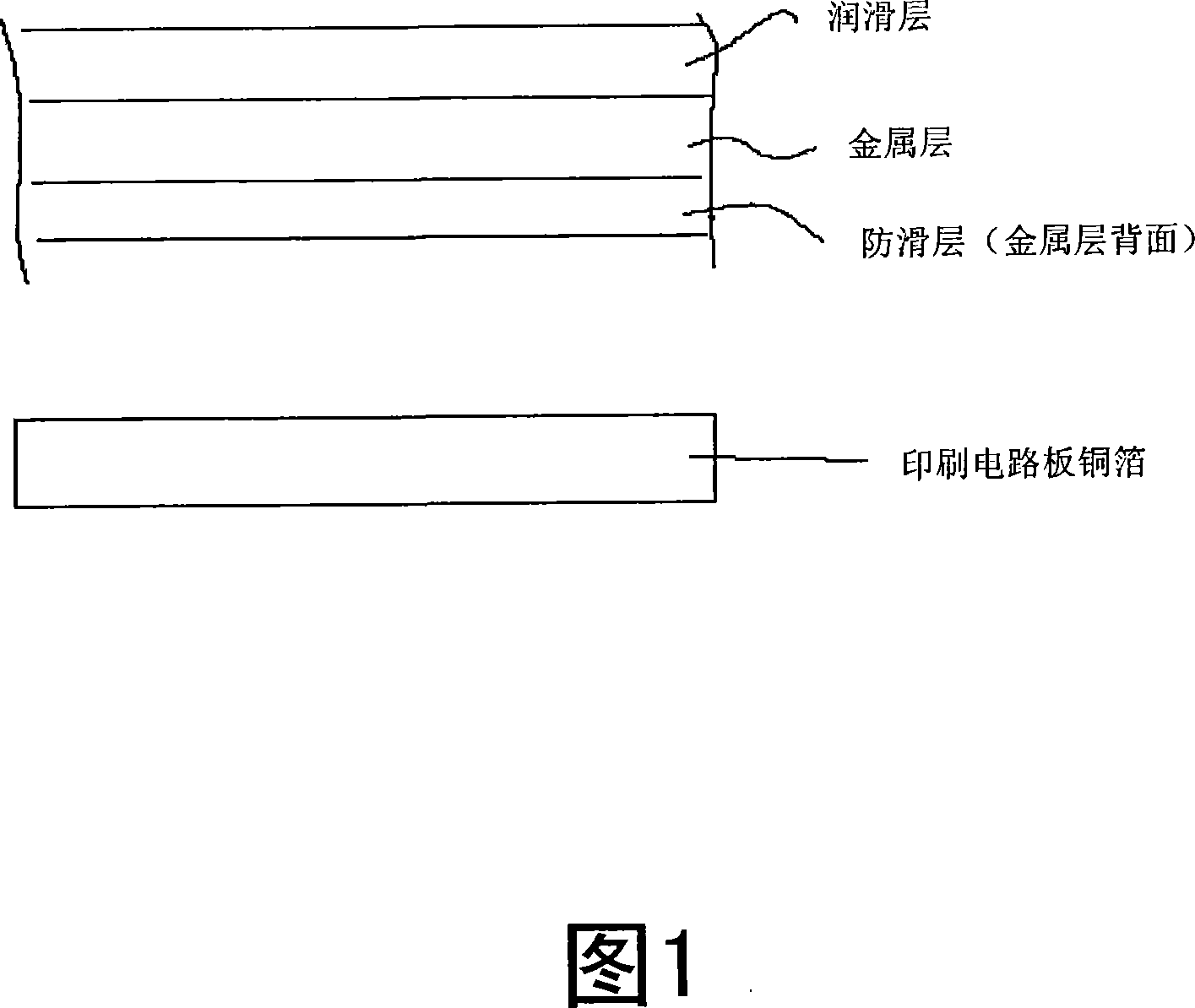

A processing procedure and sheet material technology, which is applied in the field of sheet materials used in the drilling process, can solve problems such as incorrect operation of the drilling machine, inability to perform hole processing operations, and weakened close contact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example 1

[0047] Manufacturing example 1: Manufacturing of anti-slip layer

[0048] Using Hanwha LLDPE grade 3120 and Samsung comprehensive product EVA120A, a film of 30 μm was extruded at a temperature of 170°C with a blown film machine (Blown Film Extruder).

manufacture example 2

[0049] Manufacturing example 2: Manufacturing of anti-slip layer

[0050] A film with a thickness of 30 μm was extruded at a temperature of 150° C. using Dow Chemical’s AFFINITY grade PL 1840 by a blown film machine (Blown Film Extruder).

manufacture example 3

[0051] Production example 3: Surface treatment of Al foil to achieve anti-slip function

[0052] When Al rolling is performed on one or both sides of an aluminum plate with a thickness of 130 μm and a purity of more than 99%, the surface roughness is improved by embossing the WORK ROLL, and the surface roughness is greater than 0.30. μm aluminum foil.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com