High electric current density electron emitter material containing zirconium tungsten base and production method thereof

An electron emitter, high current density technology, applied in the discharge tube solid thermionic cathode, electrode system manufacturing, discharge tube main electrode, etc. The effect of improved density and emission uniformity, uniform pore distribution, and narrow pore size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] 1) Use tungsten powder with an average particle size of 3.39 μm, anneal in a hydrogen furnace at 1200 ° C, and pass through a 80-mesh sieve after crushing;

[0018] 2) Weigh 96g of tungsten powder and 4g of zirconia with an average particle size of 200nm and grind together for 24h;

[0019] 3) Take 2g of the mixed powder and place it in a Φ7.5mm high-precision mold for pre-molding with a pressure of 70MPa. The preformed green body is isostatically pressed, the forming pressure is 350MPa, the holding time is 30s, and the pressed cathode green body is formed;

[0020] 4) Sinter in a hydrogen furnace at 1700°C for 3 hours; take it out and process it into a porous zirconium-tungsten matrix of Φ3×1.5mm;

[0021] 5) Place in aluminate powder, immerse in a hydrogen atmosphere at 1650°C for 5 minutes, remove the floating salt after immersion, and obtain an electron emitter;

[0022] 6) Heater is installed to make cathode;

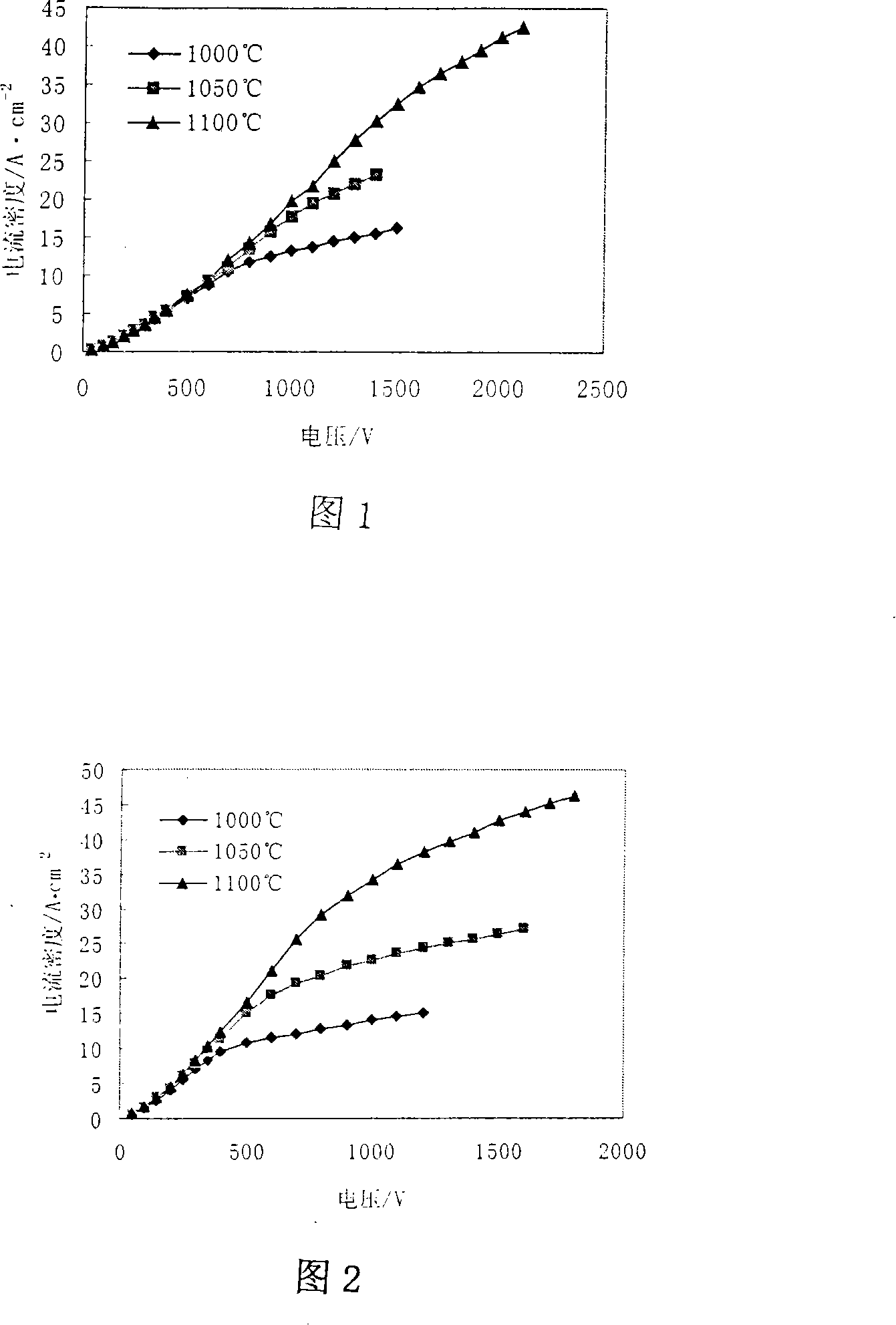

[0023] 7) Test the emission performance of the cath...

Embodiment 2

[0025] 1. Use tungsten powder with an average particle size of 3.39 μm to anneal in a hydrogen furnace at 1700 ° C, and pass through an 80-mesh sieve after crushing;

[0026] 2. Weigh 98g of tungsten powder and 2g of zirconia with an average particle size of 400nm and grind together for 24h;

[0027] 3. Take 2g of the mixed powder and place it in a Φ7.5mm high-precision mold for pre-molding with a pressure of 70MPa. The preformed green body is isostatically pressed, the forming pressure is 300MPa, the holding time is 30s, and the pressed cathode green body is formed;

[0028] 4. Sinter in a hydrogen furnace at 1950°C for 1 hour; take it out and process it into a porous zirconium-tungsten matrix of Φ3×1.5mm;

[0029] 5. Put it in aluminate powder, soak it in a hydrogen atmosphere at 1750°C for 1 minute, remove the floating salt after soaking, and make an electron emitter.

[0030] 6. Install the heater and make the cathode.

[0031] 7. Test the emission performance of the ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com