Testing method and device for anisotropic permeability

A technology of anisotropy and testing methods, applied in the direction of measuring devices, flow characteristics, instruments, etc., can solve incorrect, difficult to accurately measure flow distribution, fail to give a method for calculating the main value of anisotropic permeability, etc. problems, to achieve the effect of improving the efficiency of experimental work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

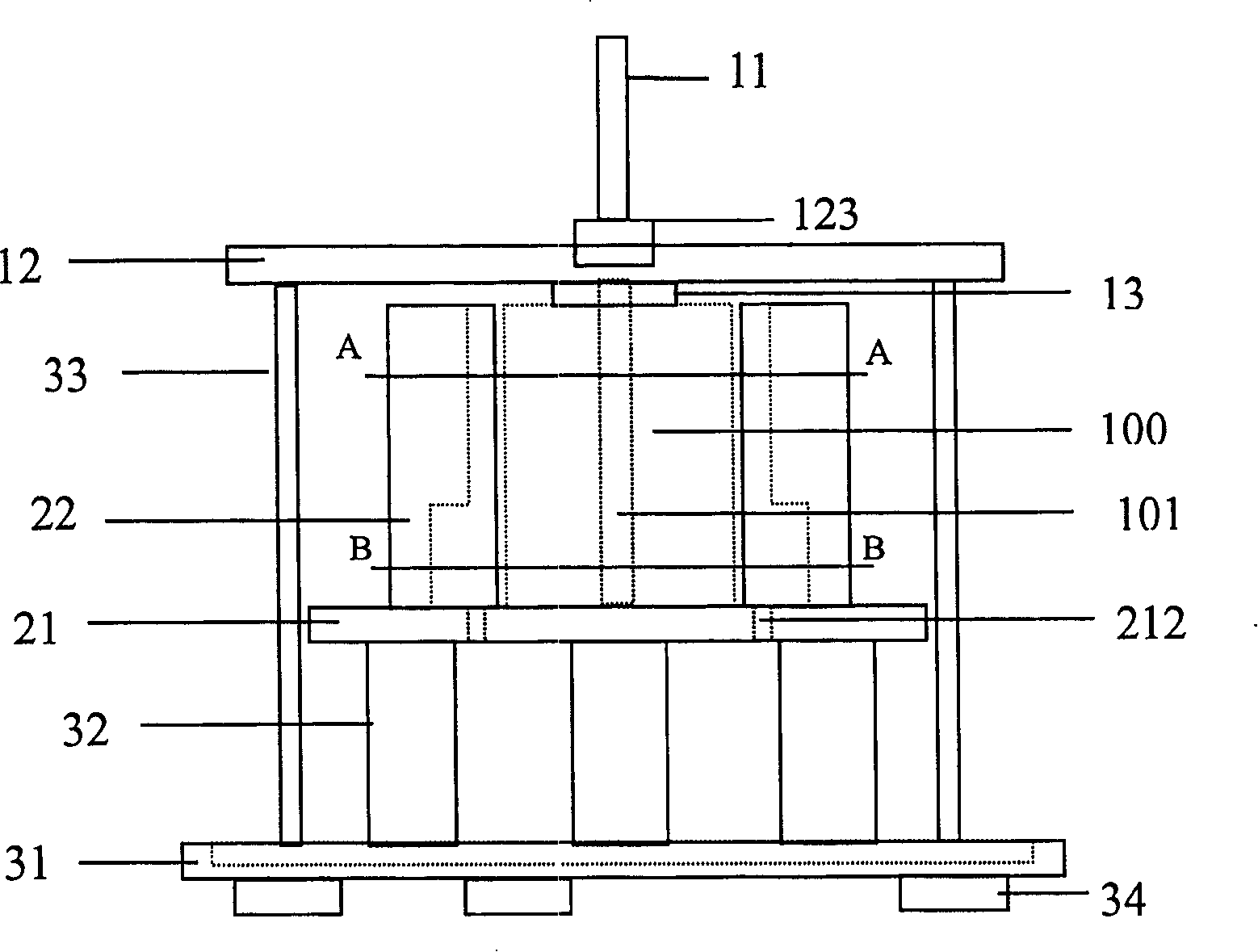

[0030] The specific implementation manner of the present invention will be further described in detail below in conjunction with the drawings and specific examples.

[0031] The present invention at first proposes a kind of test method of anisotropic permeability, comprises the following steps:

[0032] The step of forming the core hole is sealing the upper and lower end surfaces of the cylindrical full-diameter core, and then drilling along the central axis to form a circular hole, wherein the diameter of the center hole is small compared to the diameter of the core;

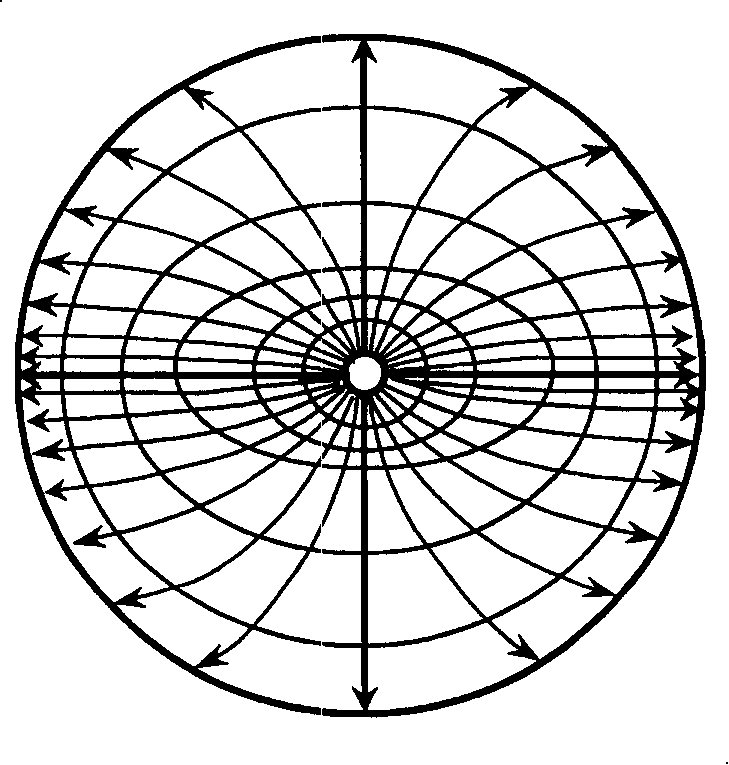

[0033] The test step is to place the core vertically, inject fluid into the center hole of the end face, the fluid enters the core body from the axis hole, forms a radial plane flow perpendicular to the axis of the core body in the core body, and then flows out from the side surface around the core;

[0034] The measurement step is to measure the flow or velocity in different directions on the outer surface of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com