Combined stove especially for ferrotitanium smelting

A technology of ferro-titanium and furnace barrel, which is applied in the field of combined furnaces for ferro-titanium smelting, which can solve the problems of high price of reducing agent aluminum, unsuitable for industrial production, and unprofessional fixed equipment, and achieve the effect of easy local maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

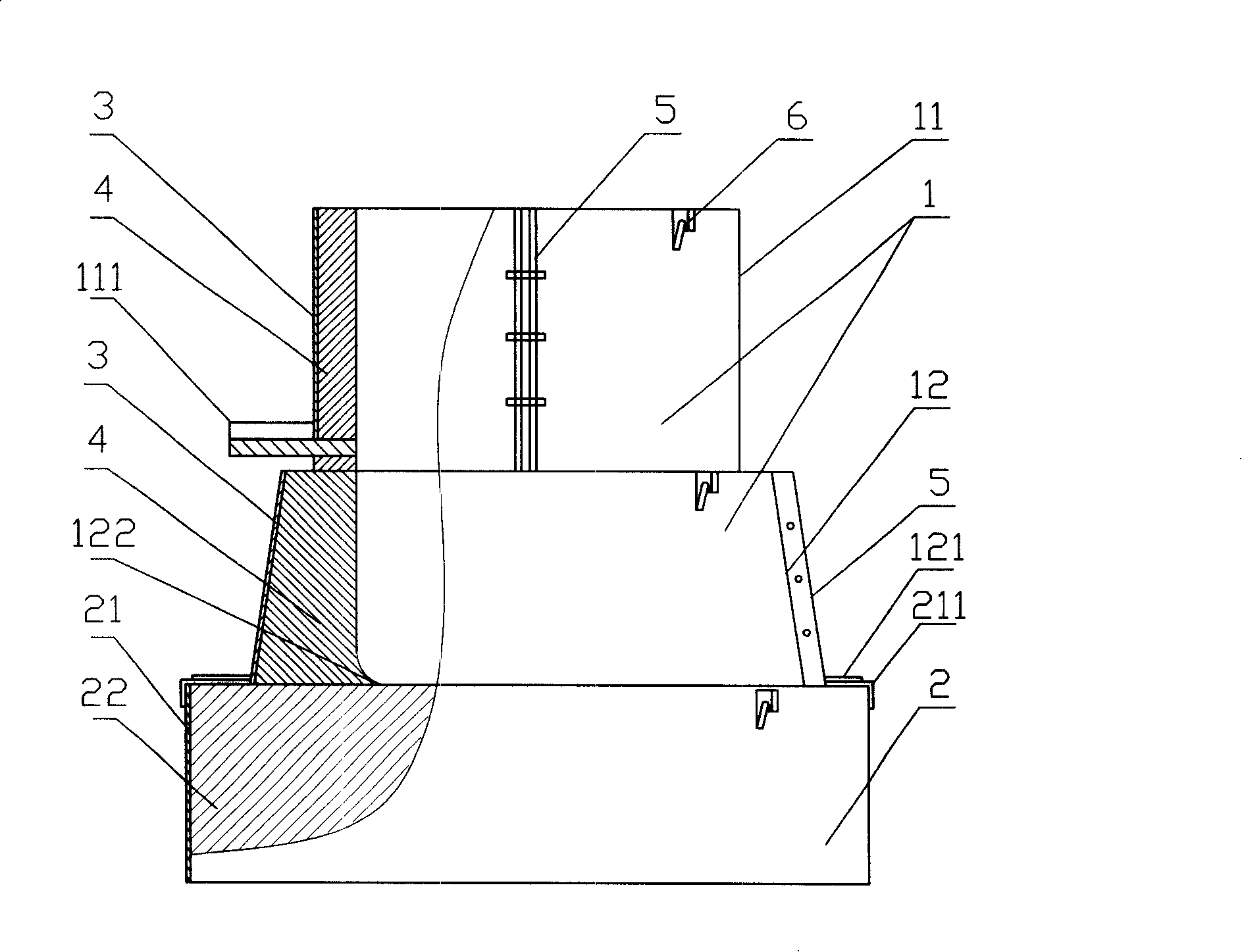

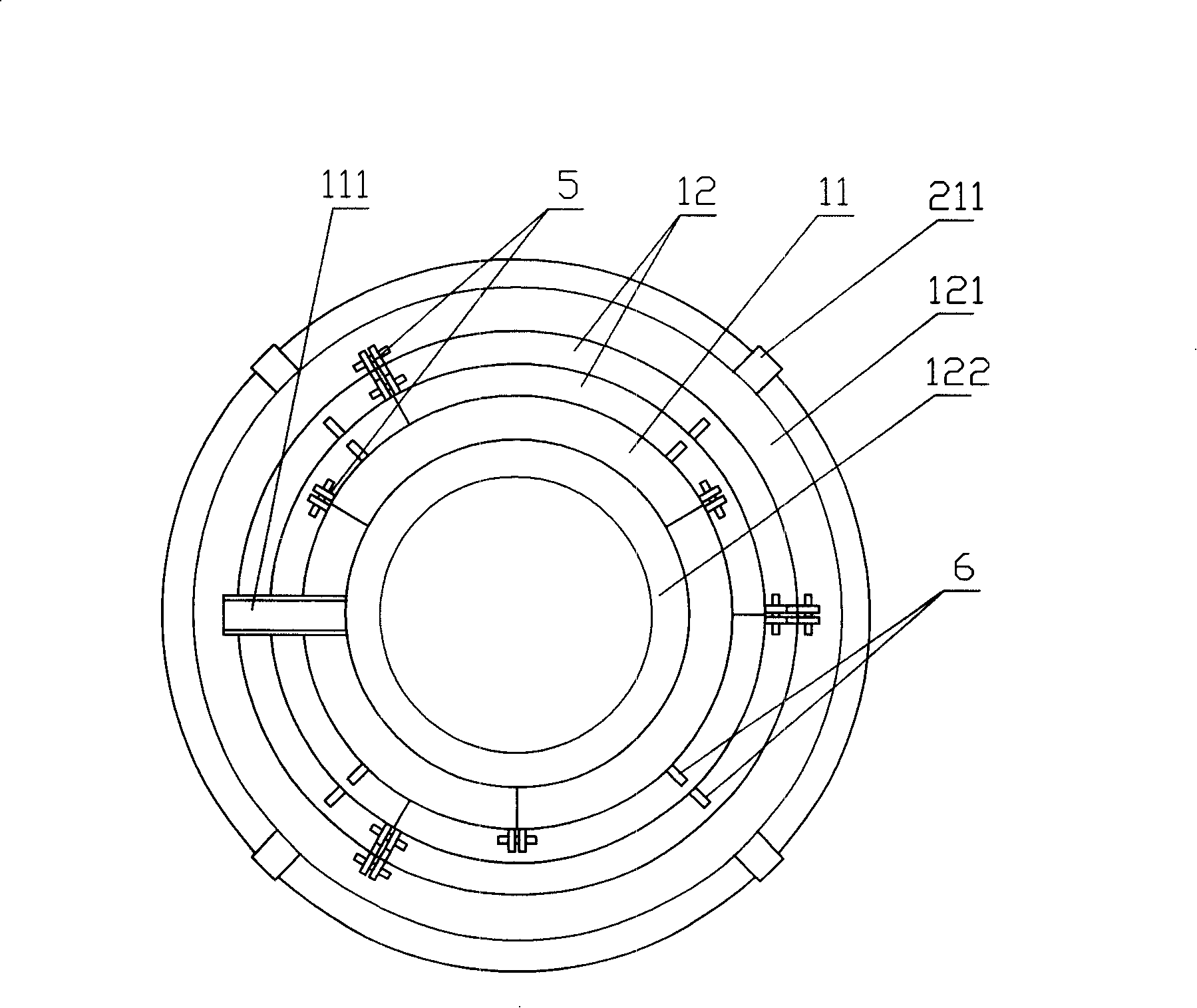

[0018] As shown in the attached figure: the combined furnace for ferro-titanium smelting is a combined detachable structure, which includes a furnace cylinder 1 and a furnace base 2 that can be easily disassembled and combined; the furnace cylinder 1 is composed of a furnace cylinder shell 3, a furnace lining block 4 and a combined hinge Composed of 5, the furnace shell 3 is a steel structure with a hook 6 on it, and the furnace lining block 4 is made of high temperature resistant materials such as magnesia, corundum or spinel, which is combined into a furnace lining through a combined hinge 5, and the shell 5 is located on the furnace lining. The outer periphery of the furnace lining can be disassembled from the combined hinge 5 into a single furnace lining block 4, and the number of furnace lining blocks 4 is not limited, and can be adjusted according to the size of the furnace body. The furnace drum 1 includes an upper furnace drum 11 and a lower furnace drum 12. There is an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| loss rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com