Method for purifying ultra-vast water and purifying device

A purification device and ultra-large-scale technology, applied in chemical instruments and methods, water aeration, water/sludge/sewage treatment, etc., can solve the problems of unrecorded air compressor data, poor water lifting effect, and inability to form air bombs, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

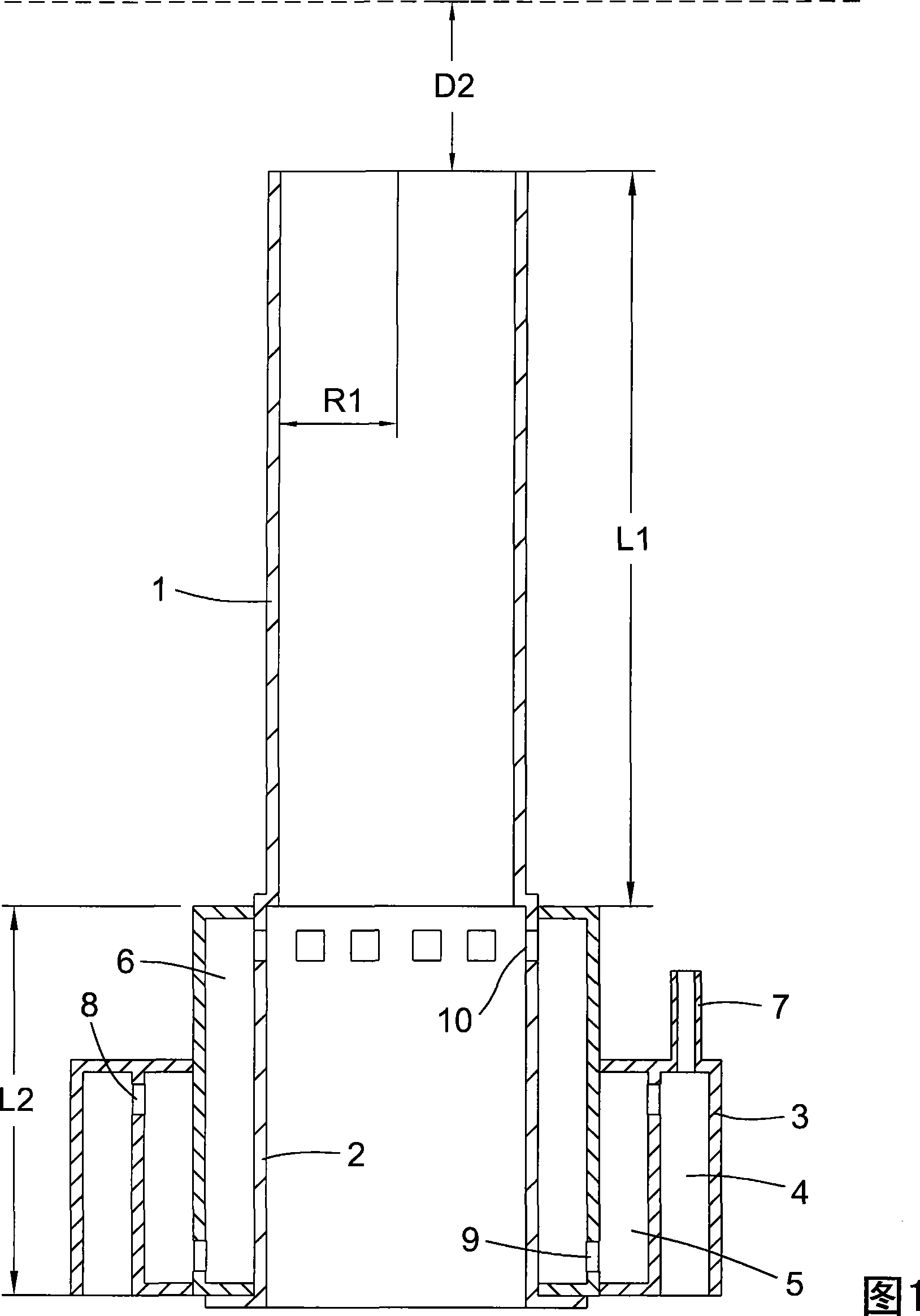

[0096] Embodiment 1, the present invention is a kind of purification method of super large amount of water, comprises the following steps:

[0097] Step 1. Select the target water area, which is a lake with a depth of 10 meters;

[0098] Step 2. Determine the reference water depth D1, which is 10 meters;

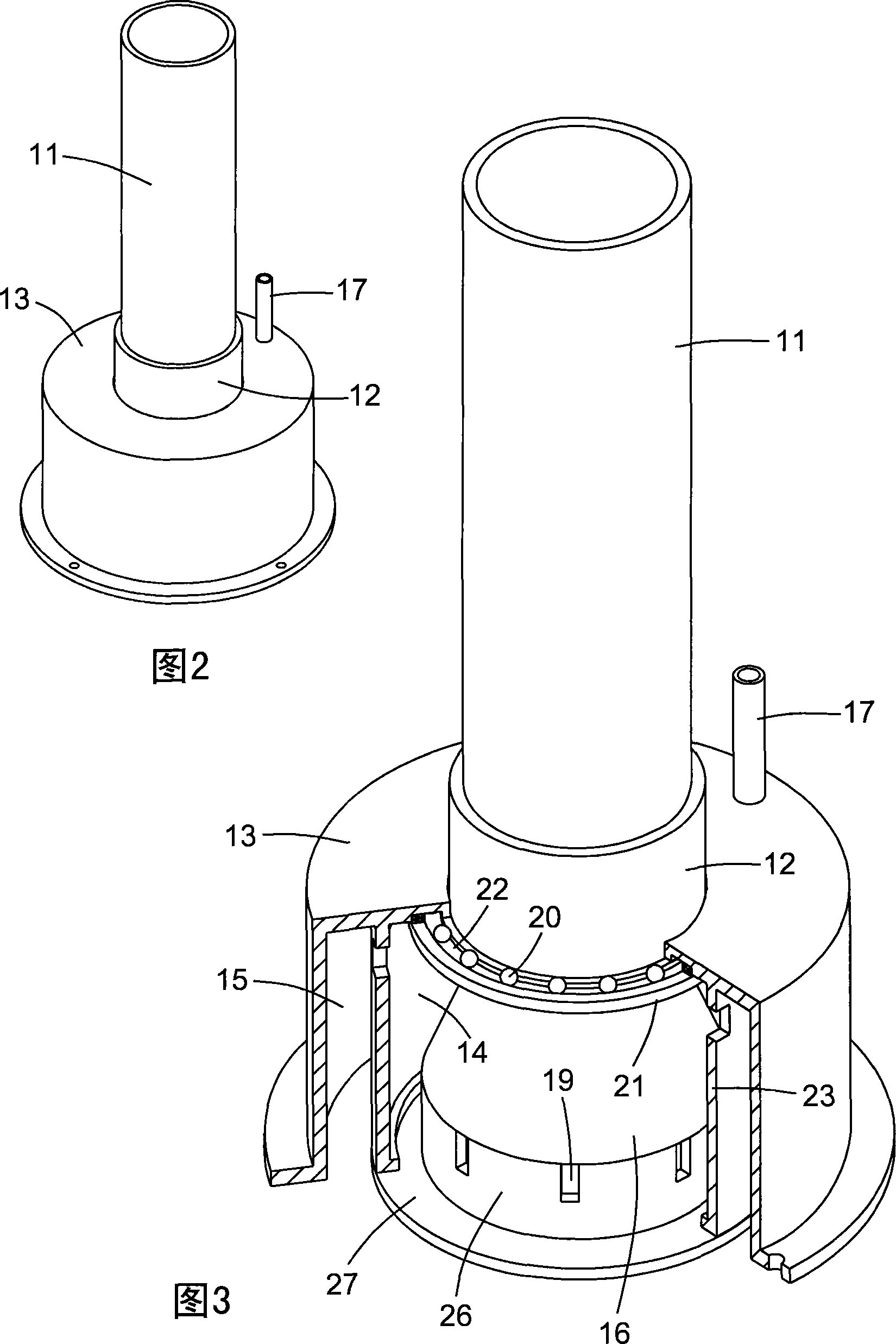

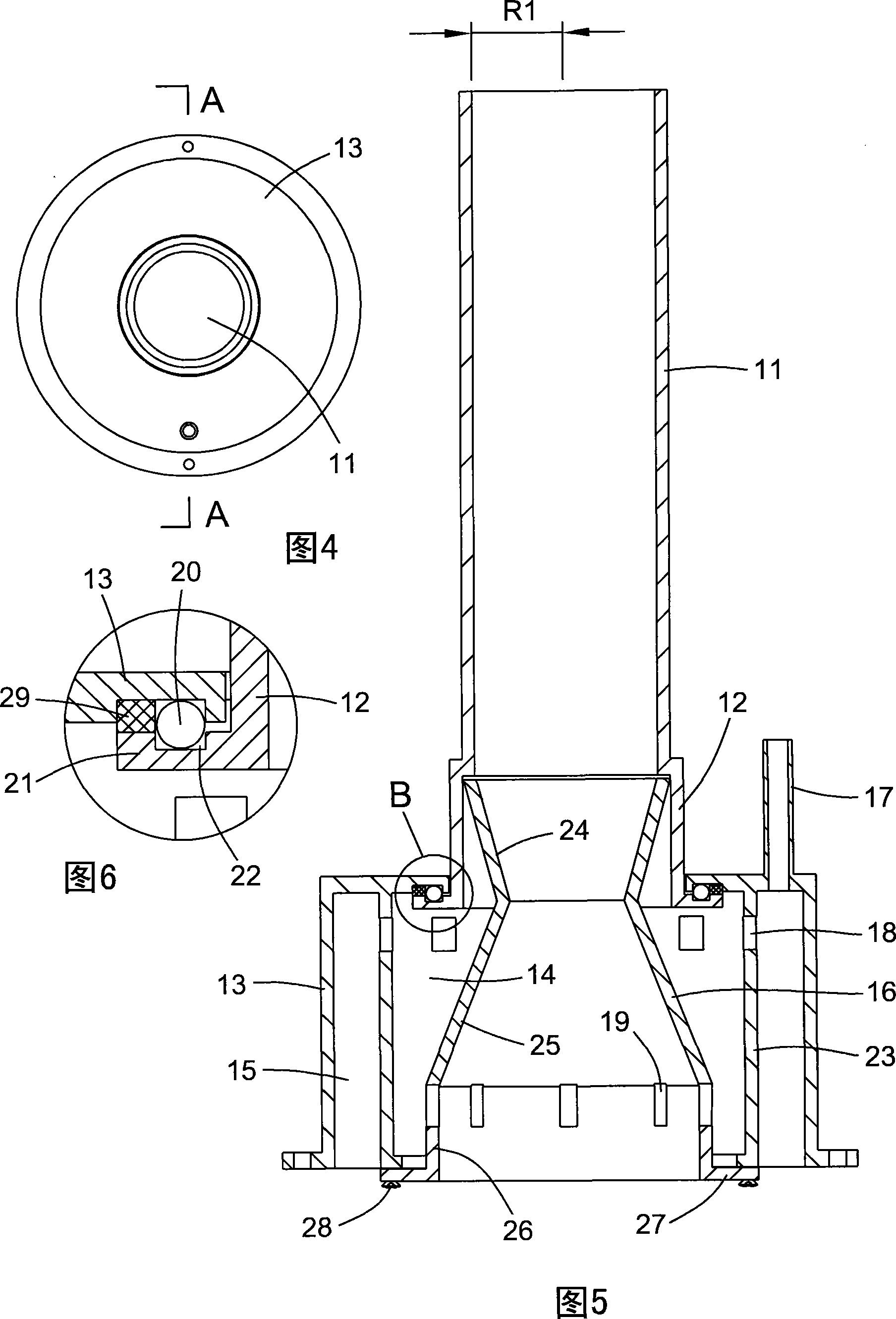

[0099] Step 3, arrange the purification device in the target water area, the purification device is an air pumping tube,

[0100] The cylinder body of the air pumping cylinder is composed of a straight pipe; the radius R1 of the cylinder body is 20cm;

[0101] The cylinder body length L1=50%D1=5 meters of the air pumping cylinder,

[0102] The cylinder mouth submersion depth D2=60%L1=3 meters of the air pumping cylinder,

[0103] Step 4, start the air compressor, input air into the inflatable chamber of the air pumping cylinder, the air pressure P1=150%P2 output by the air compressor, P2 is the water pressure in the inflatable chamber;

[0104] P2=ρgh, where ρ is liquid ...

Embodiment 2

[0106] Embodiment two, the present invention is a kind of super large amount of water purification method, comprises the following steps:

[0107] Step 1. Select the target water area, which is a lake with a depth of 12 meters;

[0108] Step 2. Determine the reference water depth D1, which is 12 meters;

[0109] Step 3, arrange the purification device in the target water area, the purification device is an air pumping tube,

[0110] The cylinder of the air pumping cylinder is composed of a straight pipe; the radius of the cylinder is R1=21cm;

[0111] The cylinder body length L1=49%D1=5.88 meters of the air pumping cylinder,

[0112] The submerged depth of the cylinder mouth of the air pumping cylinder D2=57% L1=3.35 meters,

[0113] Step 4, start the air compressor, input air into the inflatable chamber of the air pumping cylinder, the air pressure P1=155%P2 output by the air compressor, P2 is the water pressure in the inflatable chamber;

[0114] P2=ρgh, where ρ is liqui...

Embodiment 3

[0116] Embodiment three, the present invention is a kind of super large amount of water purification method, comprises the following steps:

[0117] Step 1. Select the target water area, which is a lake with a depth of 15 meters;

[0118] Step 2. Determine the reference water depth D1, which is 15 meters;

[0119] Step 3, arrange the purification device in the target water area, the purification device is an air pumping tube,

[0120] The cylinder body of the air pumping cylinder is composed of a straight pipe; the radius R1 of the cylinder body is 22cm;

[0121] The cylinder body length L1=48%D1=7.2 meters of the air pumping cylinder;

[0122] The mouth submerged depth D2=55%L1=3.96 meters of the air pumping cylinder;

[0123] Step 4, start the air compressor, input air into the inflatable chamber of the air pumping cylinder, the air pressure P1=160%P2 output by the air compressor, P2 is the water pressure in the inflatable chamber;

[0124] P2=ρgh, where ρ is liquid dens...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com