Wire lead solder device for screw energy conserving lamp assembling production

An energy-saving lamp and soldering technology, which is applied to tin feeding devices, auxiliary devices, welding equipment, etc., can solve the problems of low work efficiency, time-consuming and laborious, and achieve the effect of improving work efficiency, simple device structure, and reducing operators.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

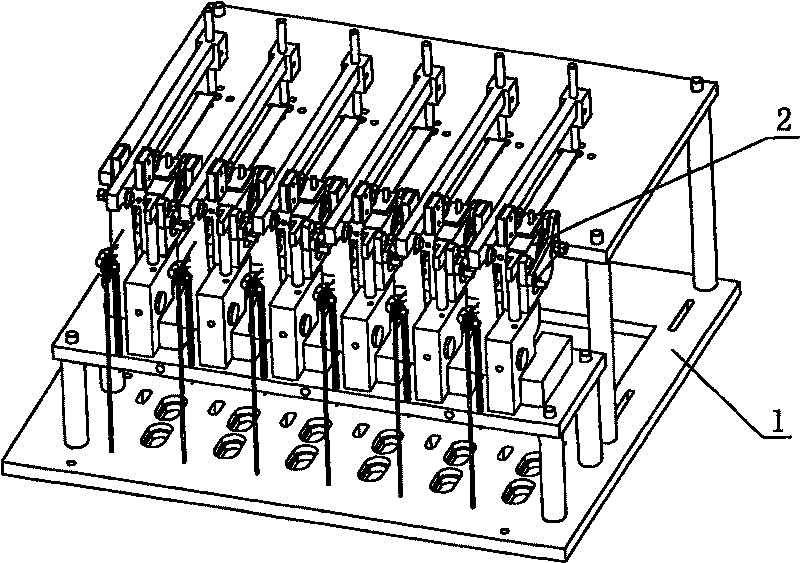

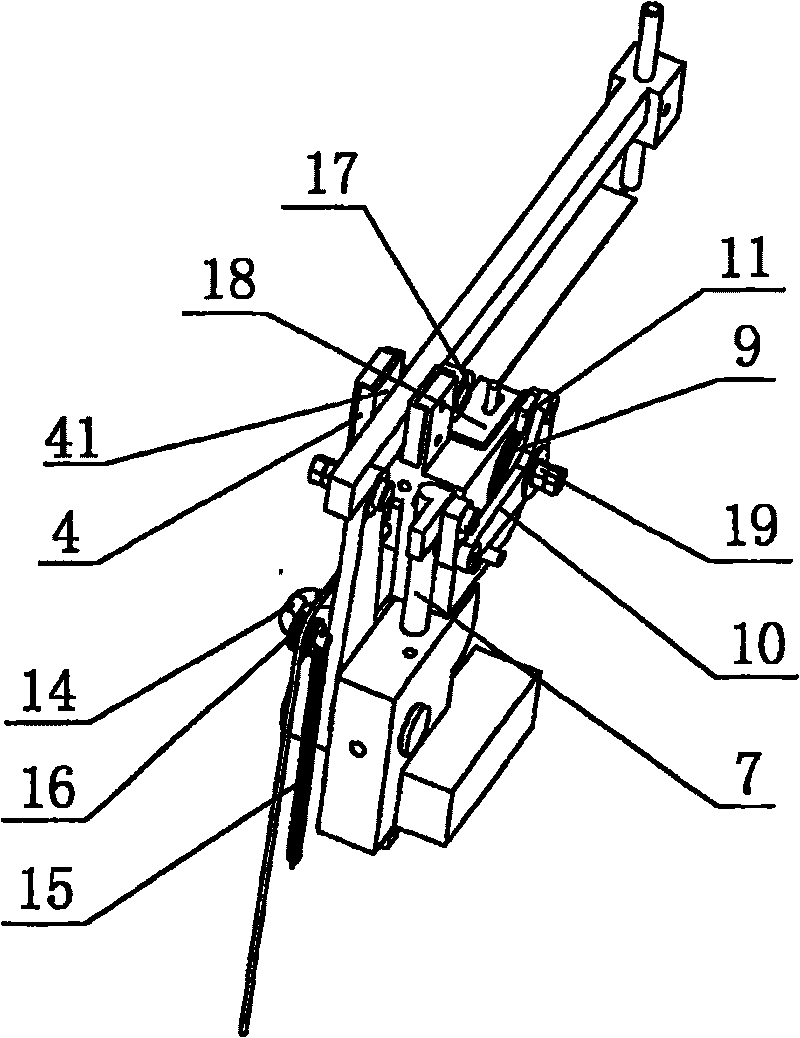

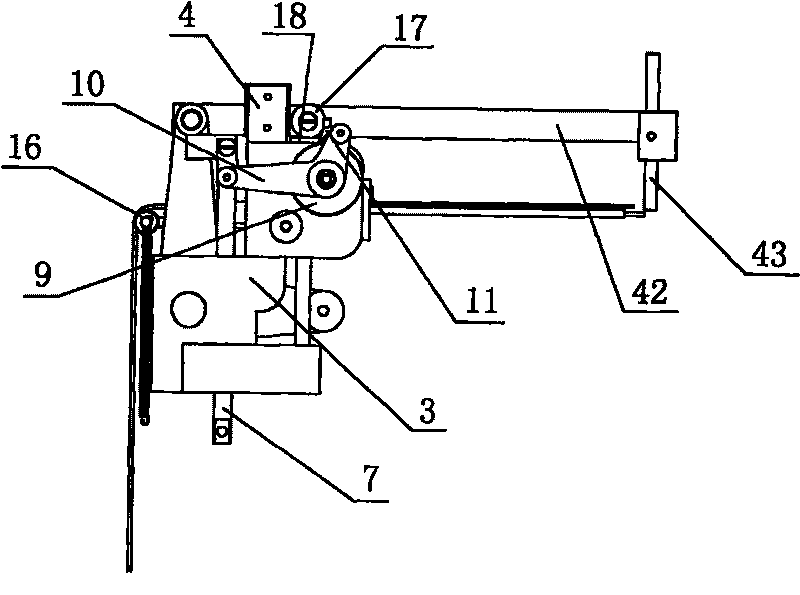

[0016] As shown in the figure, a lead wire soldering device for the assembly and production of screw energy-saving lamps includes six soldering mechanisms 2 arranged on a work station 1, and the soldering mechanisms 2 include a base 3 and a first cylinder push rod 5 , the base 3 is pivotally connected with a large rocker arm 8, one end of the large rocker arm 8 is pivotally connected with the second cylinder ejector rod 6, the other end of the large rocker arm 8 is pivotally connected with a cantilever 42, and the base 3 is integrally provided with a guide Block 4, the guide block 4 is provided with a chute 41, the cantilever 42 passes through the chute 41 and is vertically provided with an iron rod 43 at the end, the cantilever 42 is axially connected with the second roller 17, and the base 3 is provided with a pad 18. The spacer 18 is arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com