Stereo grid shaped bone filler and manufacturing method thereof

A technology of bone filler and three-dimensional grid, which is applied in bone implants, prostheses, medical science, etc., can solve the problems of foreign body sensation, hindering the self-growth and repair of soft tissue or bone tissue, and difficult to become a qualified bone scaffold structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

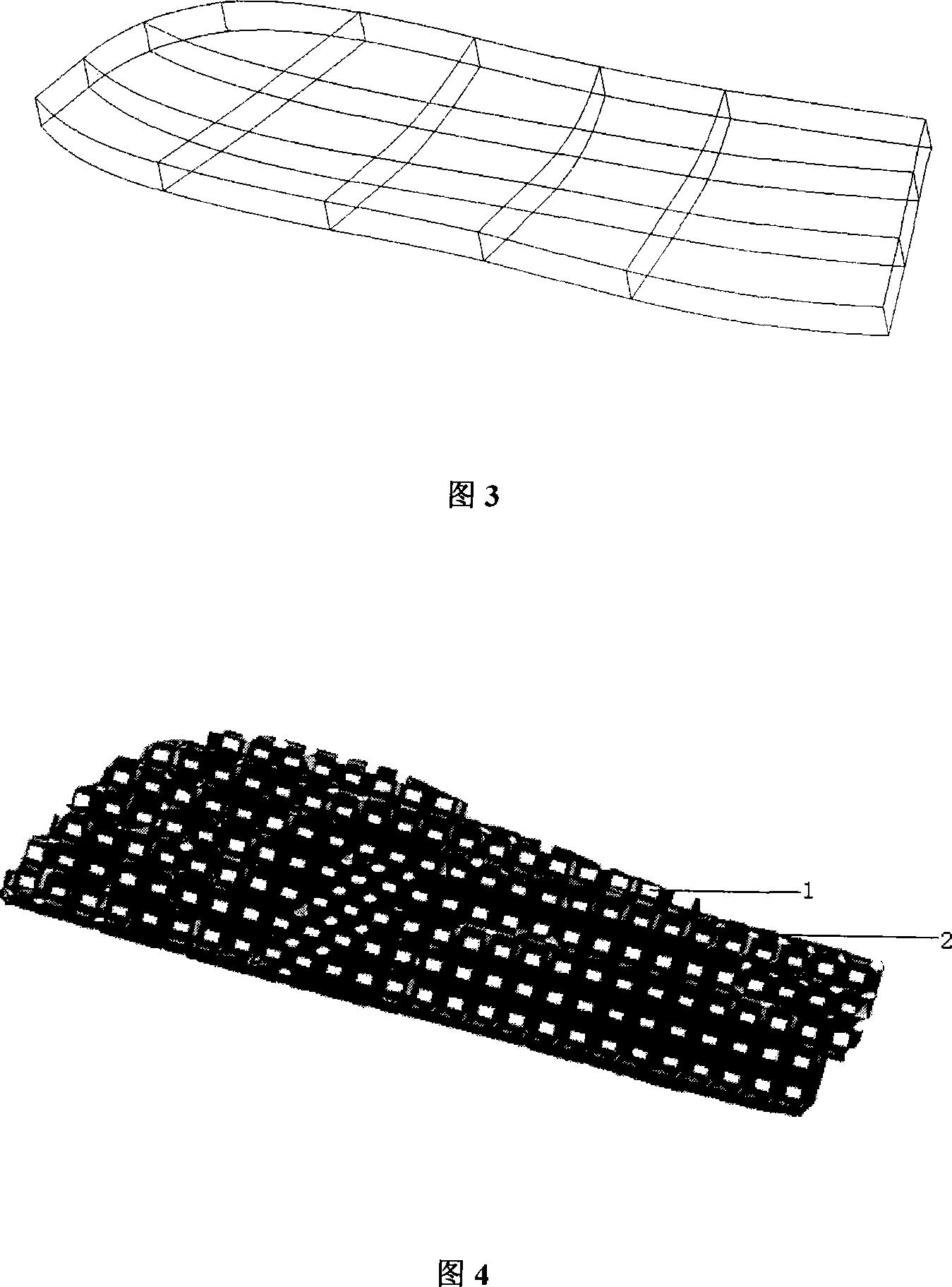

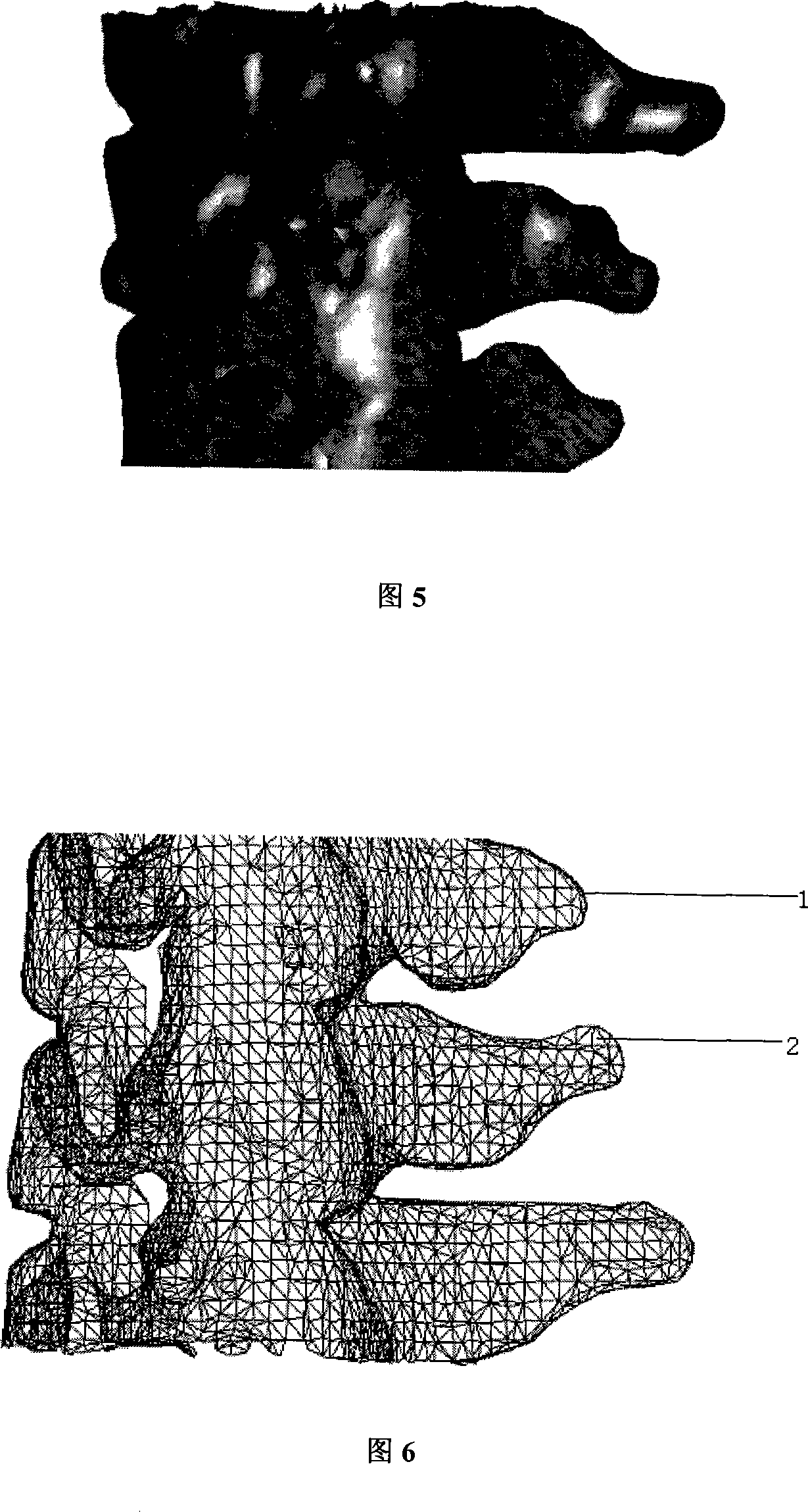

[0037] The present invention will be further described in detail below in conjunction with the accompanying drawings (FIG. 1-FIG. 6).

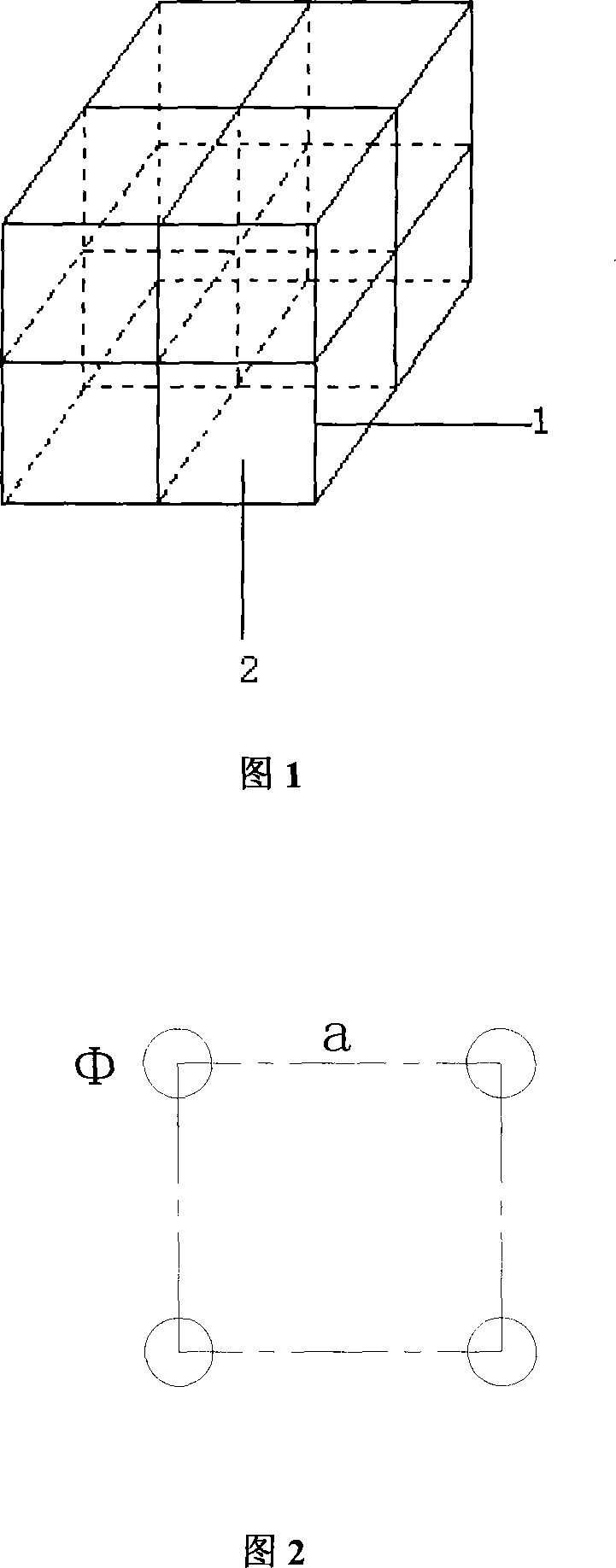

[0038] Fig. 1 is a schematic diagram of the structure of the three-dimensional mesh bone filler of the present invention. As shown in FIG. 1 , the three-dimensional mesh bone filler includes a three-dimensional structure, and honeycomb cavities are distributed along all surfaces of the three-dimensional structure. The honeycomb cavities are arranged in a regular grid. The regular grid 2 is a square array constructed by the cylindrical sides 1, obviously, it can also be a rectangular array, a triangular array, a rhombus array or a hexagonal array, or other irregular polygonal shapes. A regular grid can also be a circular array or an elliptical array.

[0039] The three-dimensional structure is a metal titanium product or a titanium alloy product. Of course, the three-dimensional structure can use other biological structural materials that me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com