A surface mounted magnetic element

A magnetic component, surface-mounted technology, applied in electrical components, inductors with magnetic cores, inductors, etc., can solve problems such as complex manufacturability, and achieve good processing technology, reliable fixing method, and good clamping effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

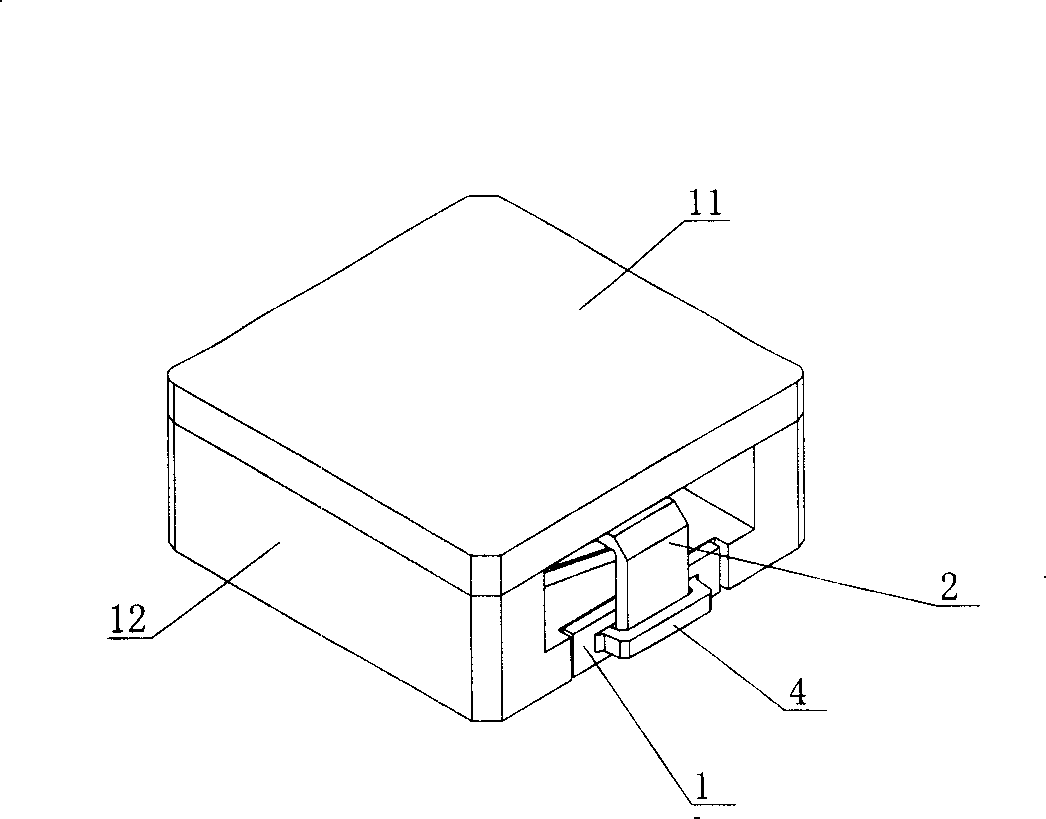

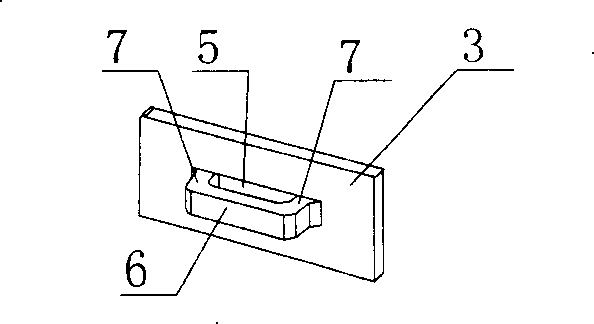

[0041] A surface-mounted magnetic component, including a coil, a magnetic core, and a metal terminal 1, wherein the metal terminal 1 is provided with a fixing part 9 for fixing with the magnetic core and a joint part for installing the coil end 2 , the joint is composed of a main body 3 of the joint, a clamp arm 4 connected to the main body 3 of the joint, and formed between the clamp arm 4 and the main body 3 of the joint for accommodating the coil end 2 The clamping space 5 constitutes.

[0042] Among them, the magnetic core is composed of a flat magnetic core 11 and an EPC magnetic core 12, the coil 11 is placed in the EPC magnetic core 12, the flat magnetic core 11 is covered on the EPC magnetic core 12, and two gaps 10 are arranged on the EPC magnetic core 12. , the two metal terminals 1 are respectively arranged on the two notches 10, and the two coil ends 2 are exposed. The joint body 3 and the arm 4 are punched and formed as a whole sheet material; the arm 4 includes ...

Embodiment 2

[0045] See Figure 10 , Figure 11 The difference between this embodiment and the first embodiment is that there are multiple clamping arms 4 on the metal terminal 1, which are arranged in parallel along the direction of the coil end 2, and the spacing between multiple clamping arms 4 is equal. Compared with the first embodiment, the fixing effect of this embodiment is better.

Embodiment 3

[0047] See Figure 12 , The difference between the present embodiment and the second embodiment is that the card arm 4 is arc-shaped. This embodiment can be used for clamping and fixing the circular or semicircular coil end 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com