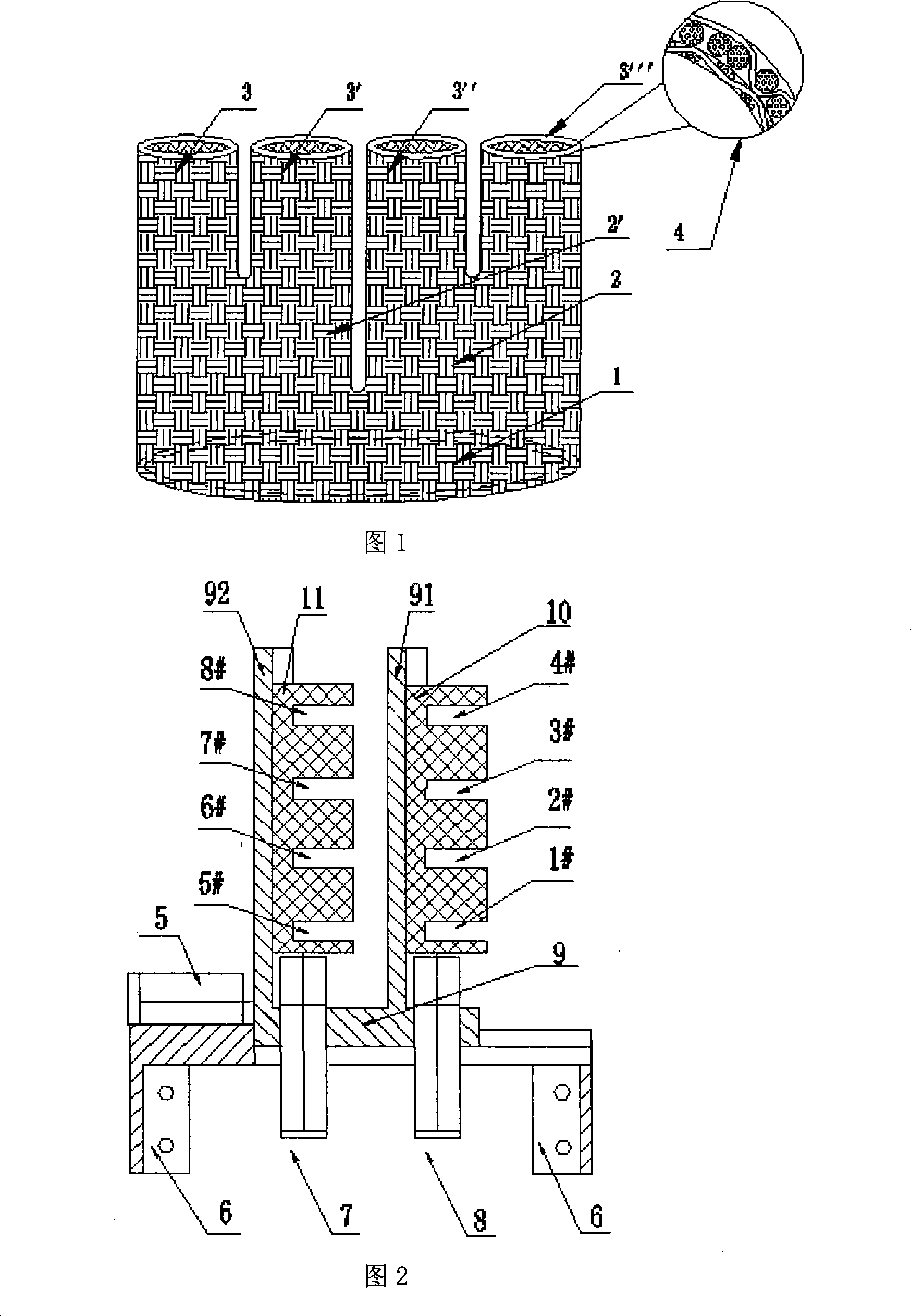

1*8 multiple shuttle box mechanism for rigid rapier weaving machine

A technology of rapier loom and shuttle box, applied in looms, textiles, textiles and papermaking, etc., can solve the problems of discontinuous weft and low precision.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

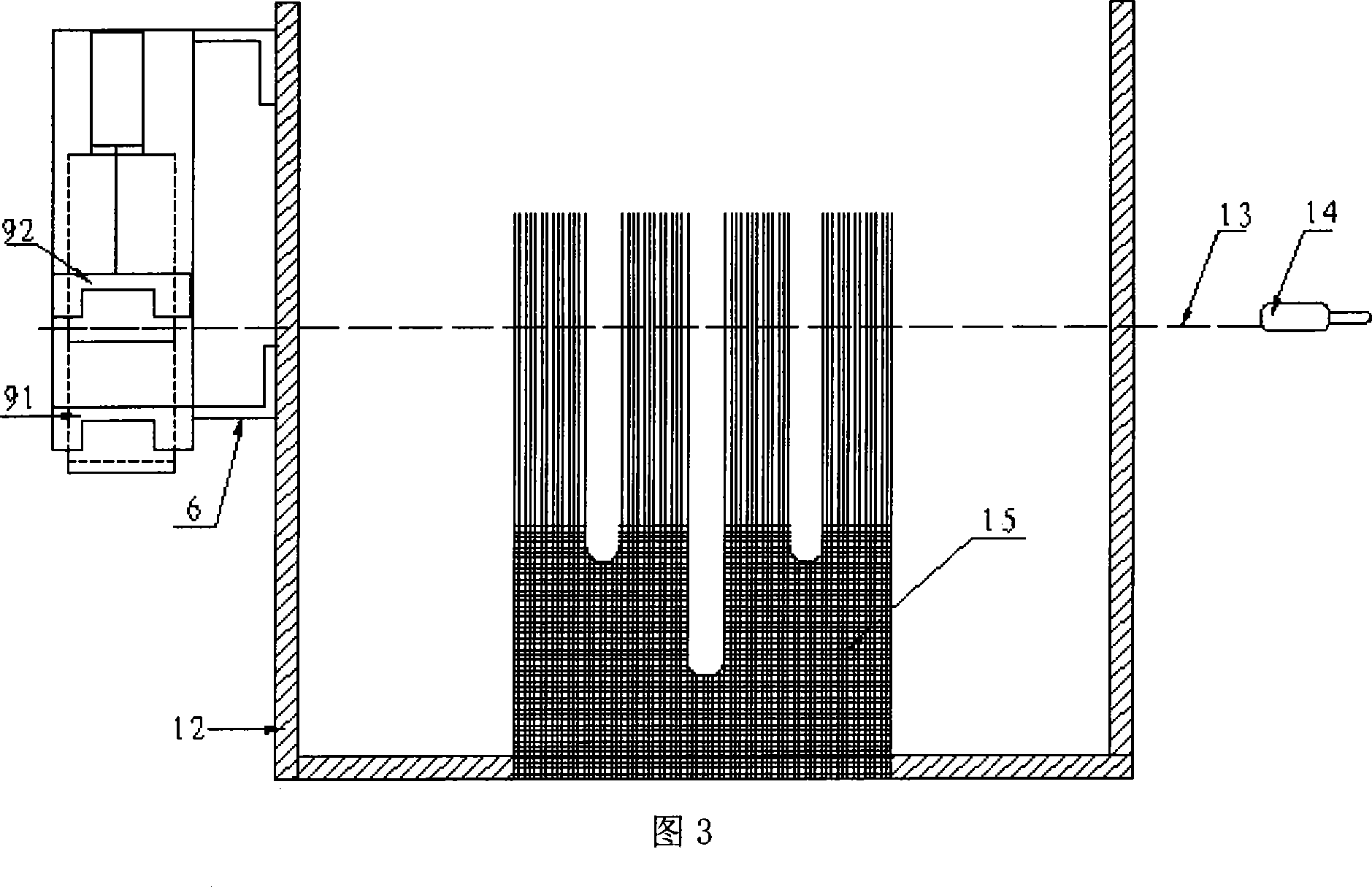

Embodiment 1

[0015] A rigid rapier loom 1×8 multi-shuttle box mechanism, the bracket 6 is fixed on the left baffle plate of the loom 12, and the material is angle steel (G18 / T9787-588); the movable slide table 9 is installed on the bracket 6, and It forms a front and rear sliding cooperation relationship with the bracket 6, and the material is aluminum alloy Z17LSI12 (G18 / T1173-595); the cylinder 5 is fixed on the bracket 6, and its piston rod is connected with the movable sliding table 9, using JB-80×80-G ordinary cylinder ; Four shuttle boxes 10 are contained on the front slide table 91 of movable slide table 9, and form sliding relationship up and down with front slide table 91, shuttle box 1 # ,2 # 、3 # 、4 # Spacing is 20mm, and material is hard plastic; # 、6 # 、7 # ,8 # The spacing is 20mm, and the material is also hard plastic; the cylinder 8 is fixed on the movable slide 9 and is located below the four-shuttle box 10, and its piston rod is connected with the four-shuttle box 1...

Embodiment 2

[0017] A rigid rapier loom 1×8 multi-shuttle box mechanism, the bracket 6 is fixed on the left baffle plate of the loom 12, and the material is aluminum alloy plate Z17LSI12 (G18 / T1173-595); the movable sliding table 9 is installed on the bracket 6 and forms a sliding fit relationship with the bracket 6, the material is aluminum alloy Z17LSI12 (G18 / T1173-595); the cylinder 5 is fixed on the frame 6, and its piston rod is connected with the movable sliding table 9, using an IC32B80-SF1FAY ordinary cylinder; Four shuttle box 10 is contained on the front slide table 91 of movable slide table 9, can slide up and down along front slide table 91, shuttle box 1 # ,2 # 、3 # 、4 # Spacing is 20mm, and material is hard plastics; Four shuttle boxes 11 are contained on the back slide table 92 of movable slide table 9, can slide up and down along front slide table 92, shuttle box 5 # 、6 # 、7 # ,8 # The spacing is 20mm, and the material is also hard plastic; the cylinder 8 is made of t...

Embodiment 3

[0019] A 1×8 multi-shuttle box mechanism for a rigid rapier loom, the bracket 6 is fixed on the left baffle plate of the loom 12, and the material is aluminum alloy plate Z17LSI12 (G18 / T1173-595); the movable sliding table 9 is installed on the bracket 6 And form a sliding fit relationship with the bracket 6, the material is aluminum alloy Z17LSI12 (G18 / T1173-595); the cylinder 5 is fixed on the frame 6, and its piston rod is connected with the movable sliding table 9, using JB-80×100-G Common cylinder; Four shuttle boxes 10 are contained on the front slide table 91 of movable slide table 9, can slide up and down along front slide table 91, shuttle box 1 # ,2 # 、3 # 、4 # Pitch is 25mm, and material is hard plastics; Four shuttle boxes 11 are contained on the rear slide table 92 of movable slide table 9, can slide up and down along front slide table 92, shuttle box 5 # 、6 # 、7 # ,8 # The spacing is 25mm, and the material is also hard plastic; the cylinder 8 is made of two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com