Weaving method of flared socks and anti-edema socks

A flared and sock-like technology, which is applied in textiles, papermaking, socks, knitting, etc., can solve the problems of inability to accurately grasp the essentials of the manufacturing method of flared loose grommets, difficulty in manufacturing, and impact on comfort, and prevent blood circulation. The effect of unsmooth, uniform holding force and flexible design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

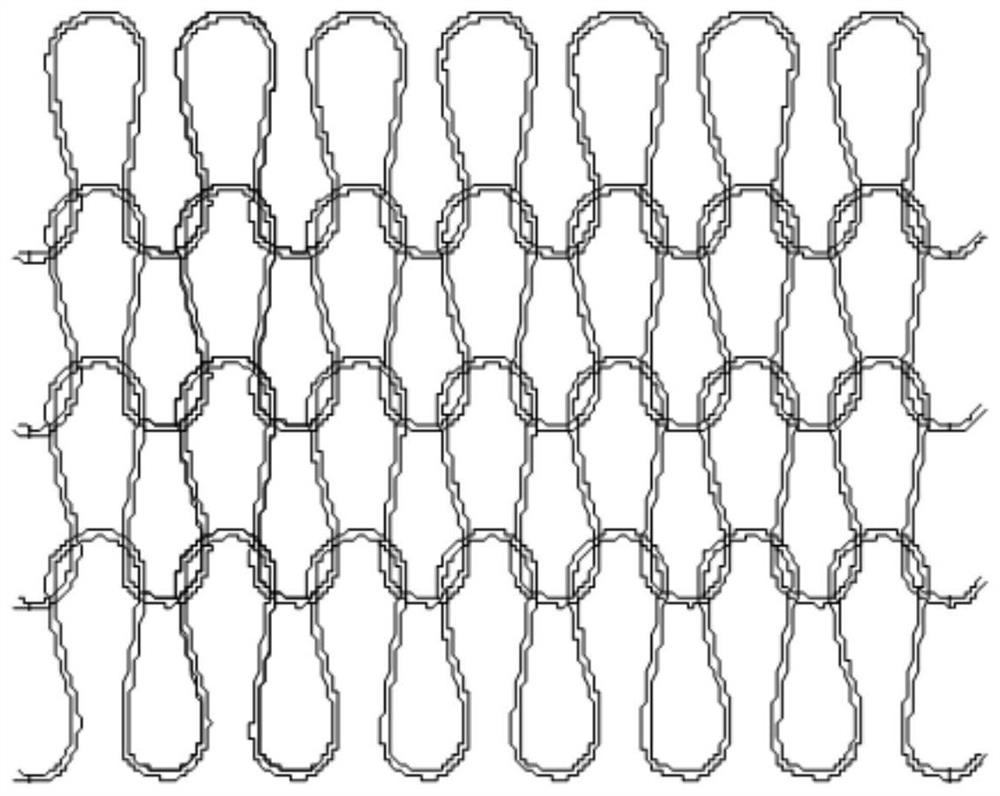

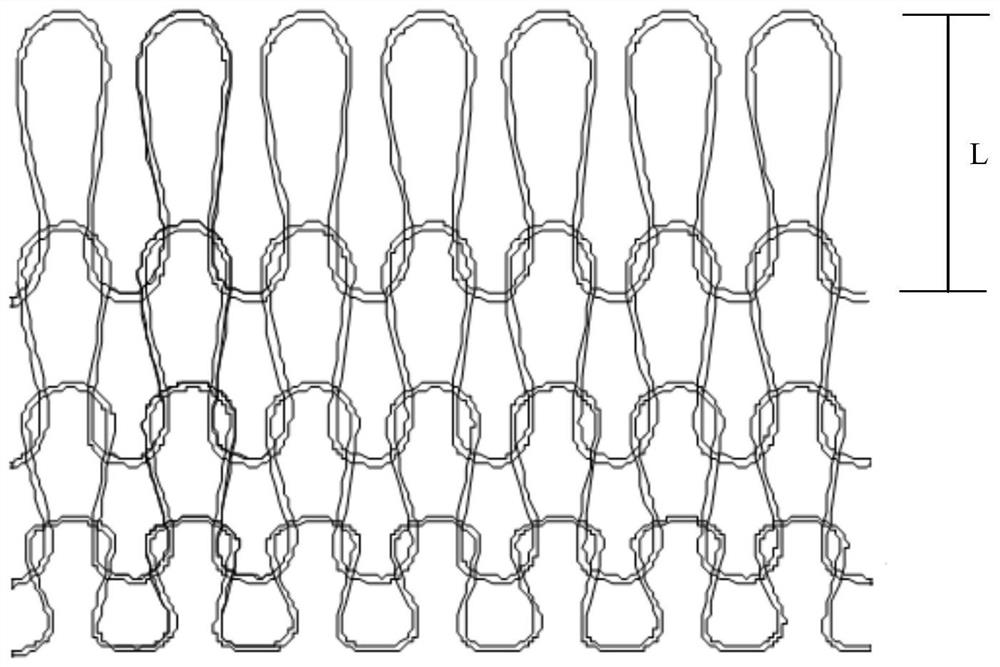

Method used

Image

Examples

Embodiment Construction

[0034] In order to further illustrate the present invention, the following series of specific examples are provided, but the present invention is not limited by these specific examples, and any modification to the present invention by those skilled in the art will be able to achieve similar results, and these modifications also include In the present invention.

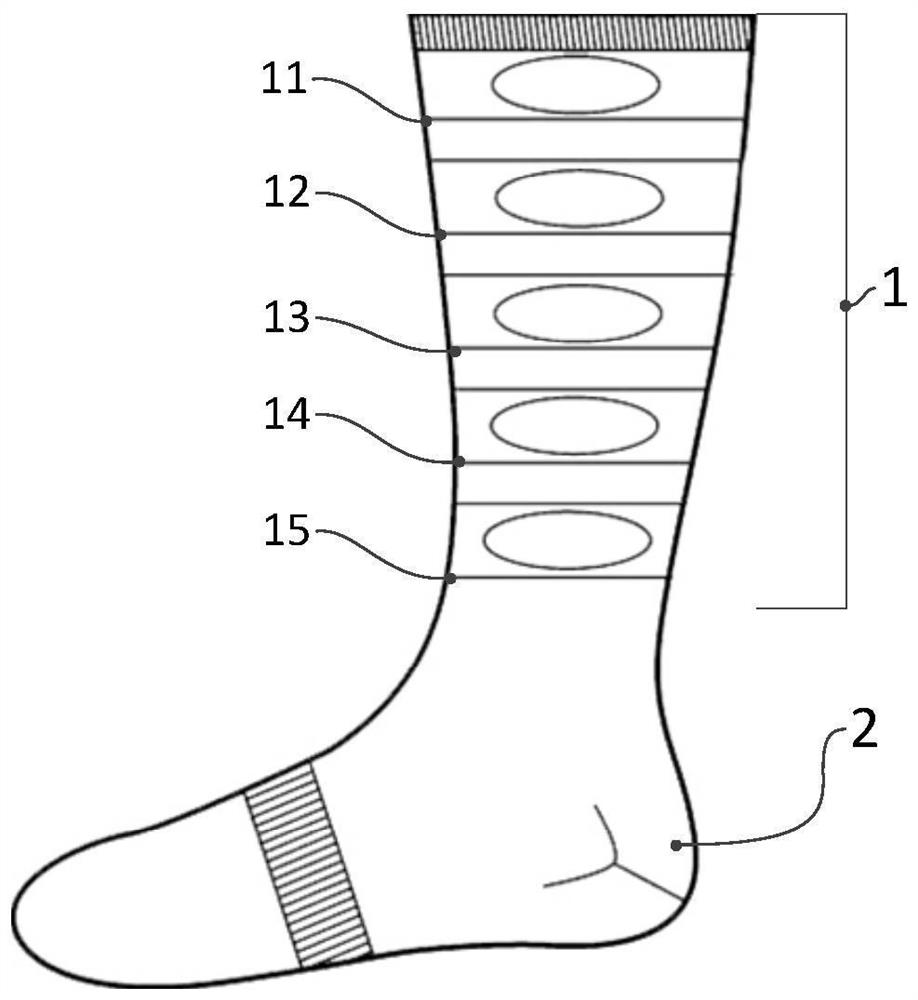

[0035] figure 2 Shown is an anti-edema sock according to a preferred embodiment of the present invention, which includes a sock shaft 1 and a sock body 2 . Its production process is as follows:

[0036] 1. Material selection

[0037] Select spandex yarn and other yarns for mixed weaving; among them, at least one spandex yarn has strong stretchability, which plays a role in generating elasticity; other yarns can be cotton yarn, which can make Socks better reflect sweat-absorbing and warm-keeping properties; other yarns can also be bamboo fiber yarns, which can make socks more breathable, soft and comfortable. Duri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com