Combing machine coiler bell mouth

A bell mouth and combing machine technology, which is applied in the direction of combing machines, textiles and papermaking, fiber processing, etc., can solve the problems of unsmooth broken sliver, scratches and scratches, etc., and achieve fully automatic sliver breaking, reliable and fully automatic The effect of breaking strips and improving the quality of strips

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

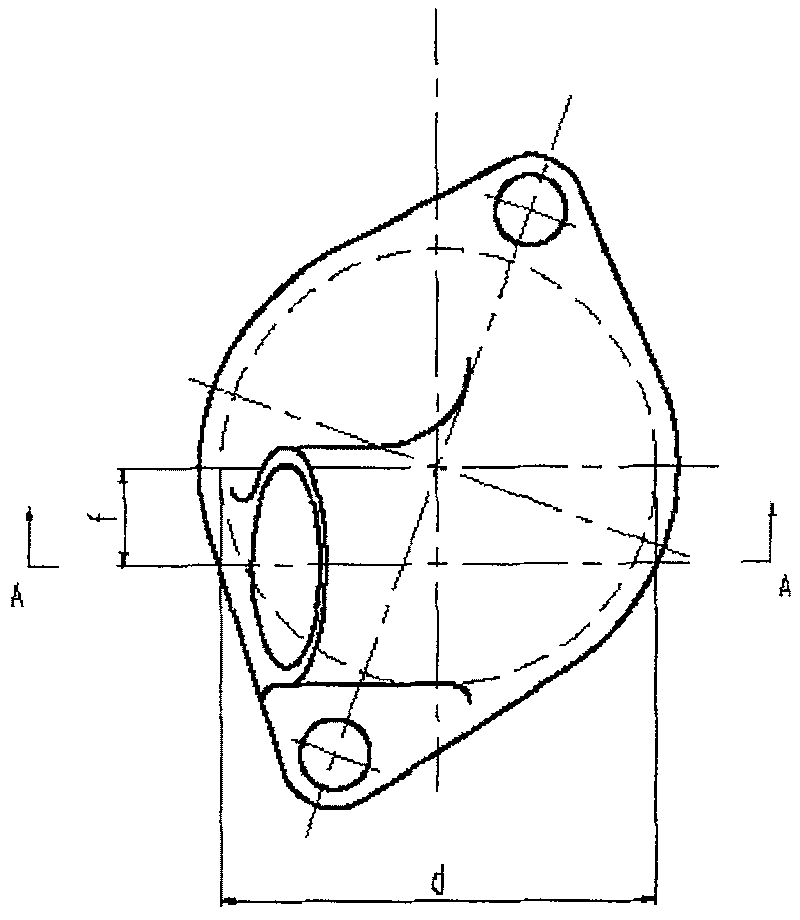

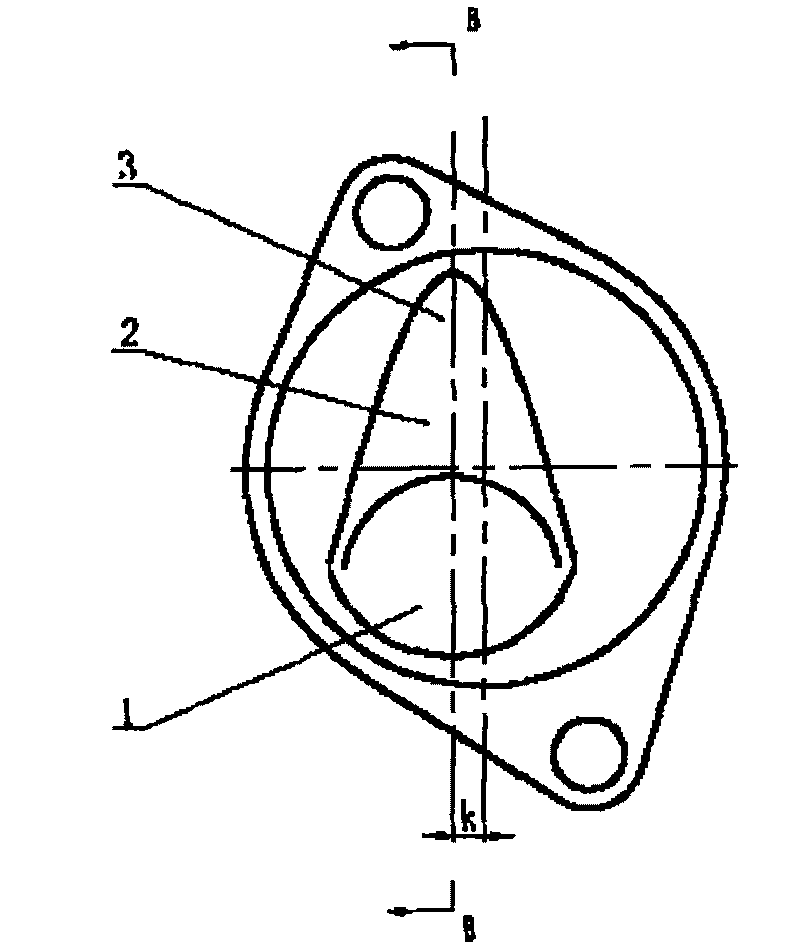

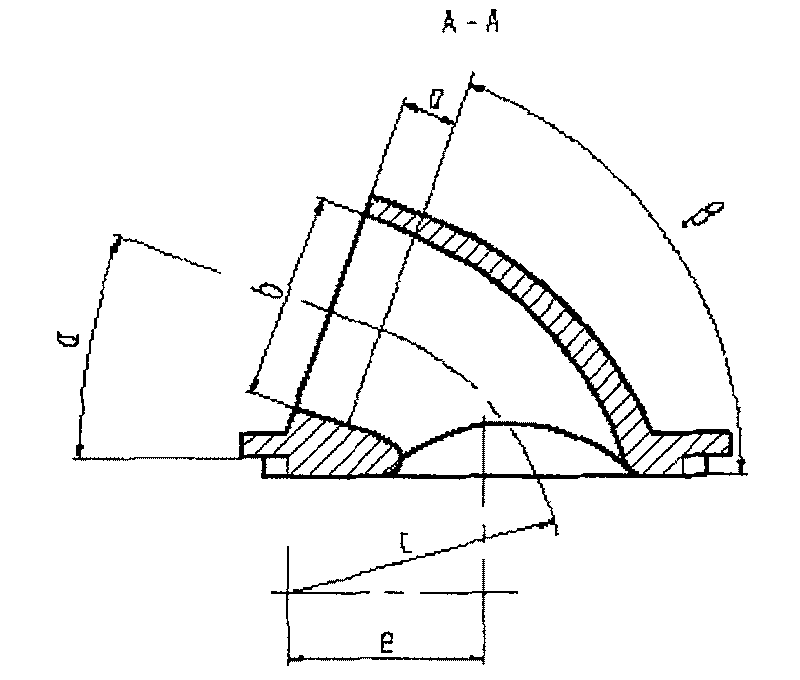

[0011] Implementation 1: A coiling bell mouth of a combing machine. On a diamond-shaped flange, a section of bent pipe is arranged. The offset distance between the center of the bent pipe and the center of the flange is f=18mm. The top of the bent pipe is a section of length a = 10mm, conical straight pipe with a taper of 1:20, the diameter of the large end of the conical straight pipe b = φ37mm, the inclination angle of this section of conical straight pipe α = 20°, and a section of conical straight pipe with a taper of 1:20 Elbow, the center line of the conical elbow is an arc with a radius of 49mm, and the center of the arc is offset from the center of the flange by e=34mm. The length of the conical elbow is based on the top surface of the flange. At the arc length of β=65°, there is a notch at the bottom of the elbow on the side of the center of the flange, and the notch transitions smoothly with the inner surface of the elbow, and the distance between its center and the ce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com