Method for preparing conductive single-layer graphite sheet modified by ionic liquid cation group

A single-layer graphite and ionic liquid technology, applied in the field of preparation of single-layer graphite sheets, can solve the problems of incompatibility of polymers and polymers, long time, environmental pollution, etc., and achieve good electrical conductivity, fast reaction speed, and environmental friendliness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

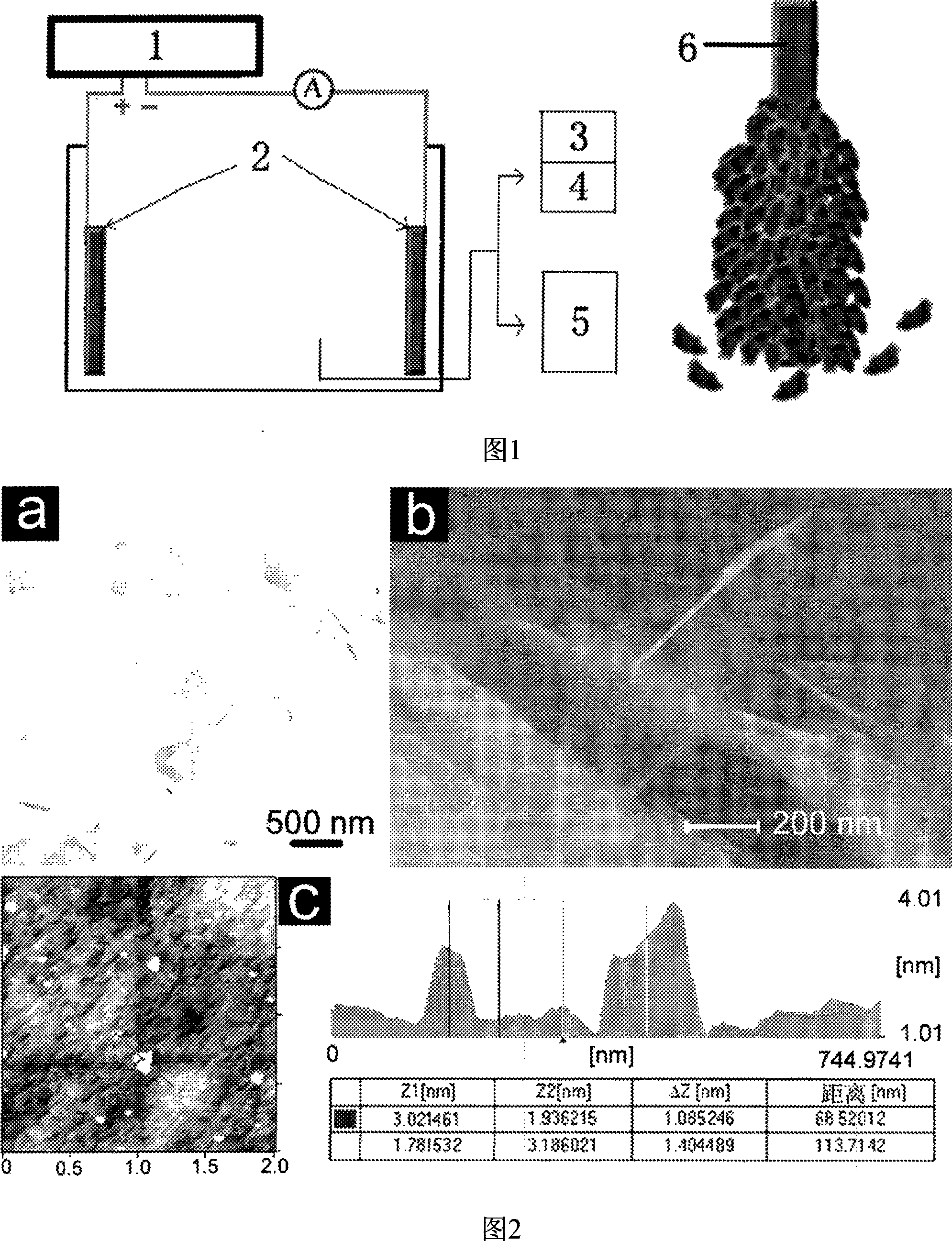

Method used

Image

Examples

Embodiment 1

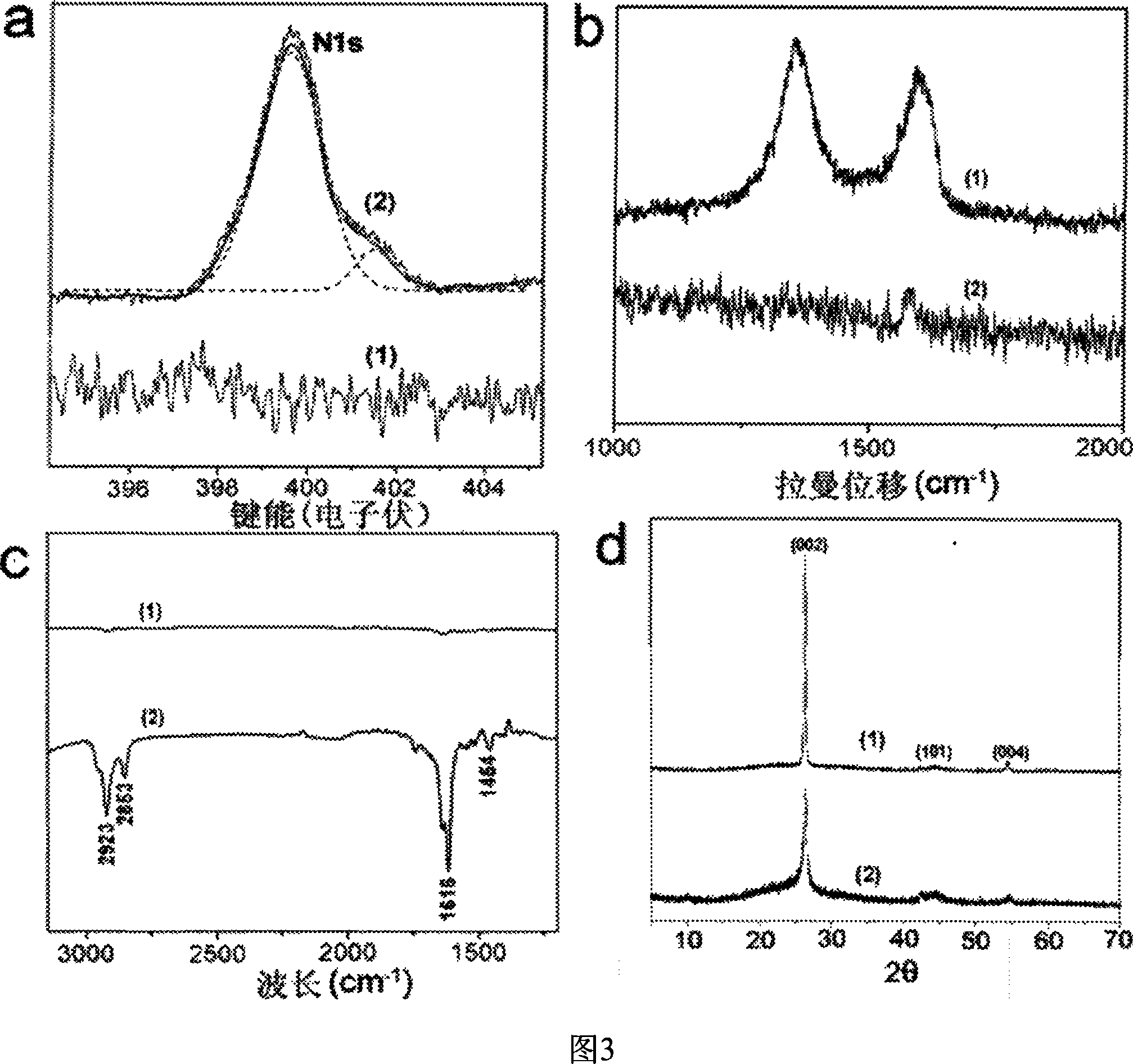

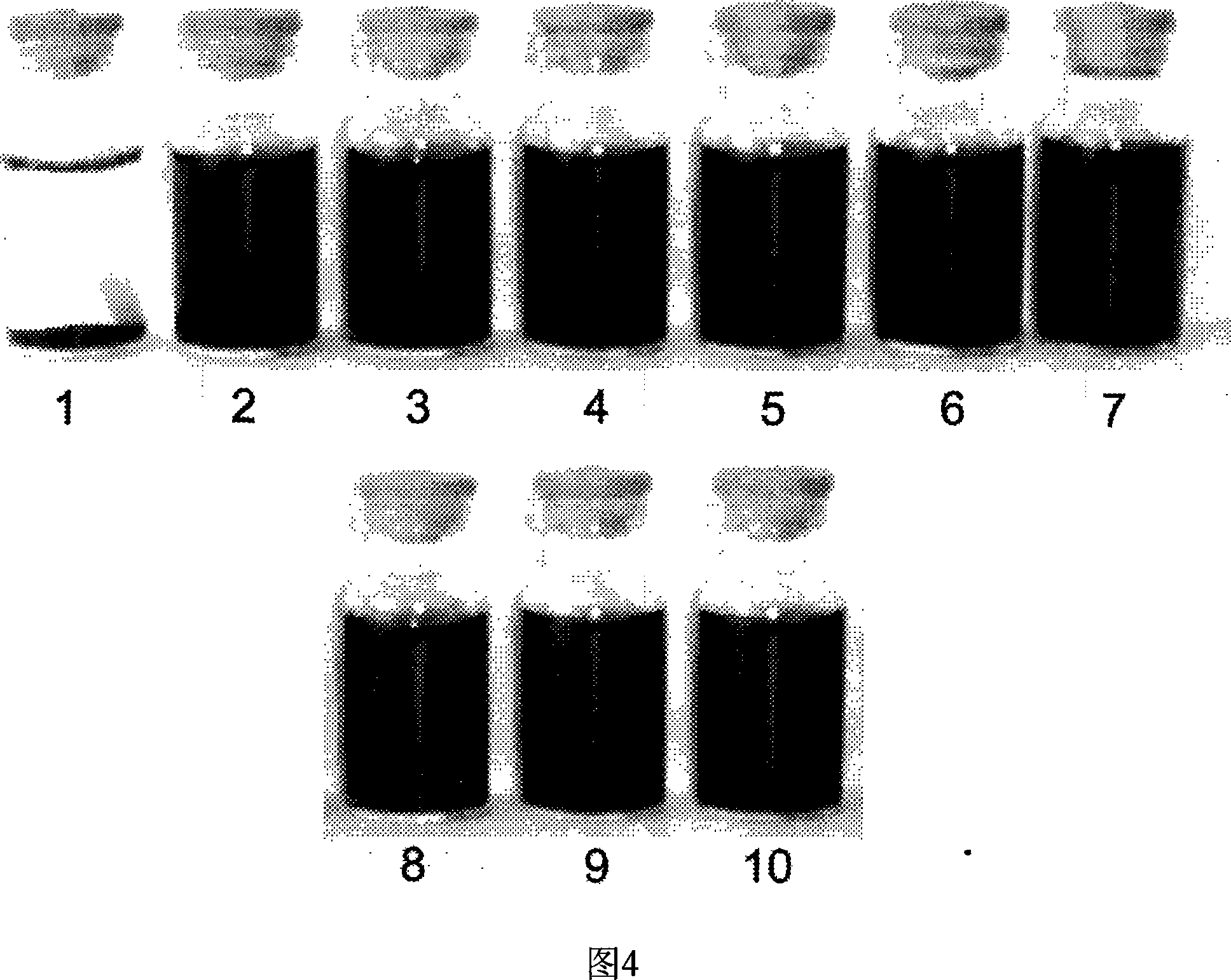

[0014] Use 1-octyl-3 methylimidazolium hexafluorophosphate and water with a volume ratio of 1:1 as the electrolyte, graphite rods as electrodes, and a constant voltage and current power supply to provide a voltage of 15 volts for 10 hours of electrolysis. After the reaction is completed, the The exfoliated single-layer graphite flake obtained was washed with absolute ethanol, and dried in a drying oven at 55° C. for 6 hours to obtain a conductive single-layer graphite flake modified with 1-octyl-3 methylimidazole ;

Embodiment 2

[0016] Use 1-octyl-3-methylimidazolium tetrafluoroborate and water with a volume ratio of 1:1 as the electrolyte, graphite rods as electrodes, and a constant-voltage and stable-current power supply to provide 15 volts for 8 hours of electrolysis. After the reaction is complete Wash the exfoliated single-layer graphite sheets obtained with absolute ethanol, and dry them in a drying oven at 55° C. for 6 hours to obtain a conductive single-layer graphite modified with 1-octyl-3 methylimidazole piece;

Embodiment 3

[0018] Use 1-octyl-3 methylimidazole chloride and water with a volume ratio of 1:5 as the electrolyte, graphite rods as electrodes, and a constant voltage and current power supply to provide a voltage of 10 volts for 6 hours of electrolysis. After the reaction is completed, the obtained The exfoliated single-layer graphite sheet was washed with absolute ethanol, and dried in a drying oven at 55°C for 6 hours to obtain a conductive single-layer graphite sheet modified with 1-octyl-3 methylimidazole;

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com