Method for manufacturing stainless steel water tap

A production method and stainless steel technology, applied in the field of faucets, can solve the problems of affecting human health, high cost, affecting appearance, etc., and achieve the effects of beautiful appearance, long service life and easy implementation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

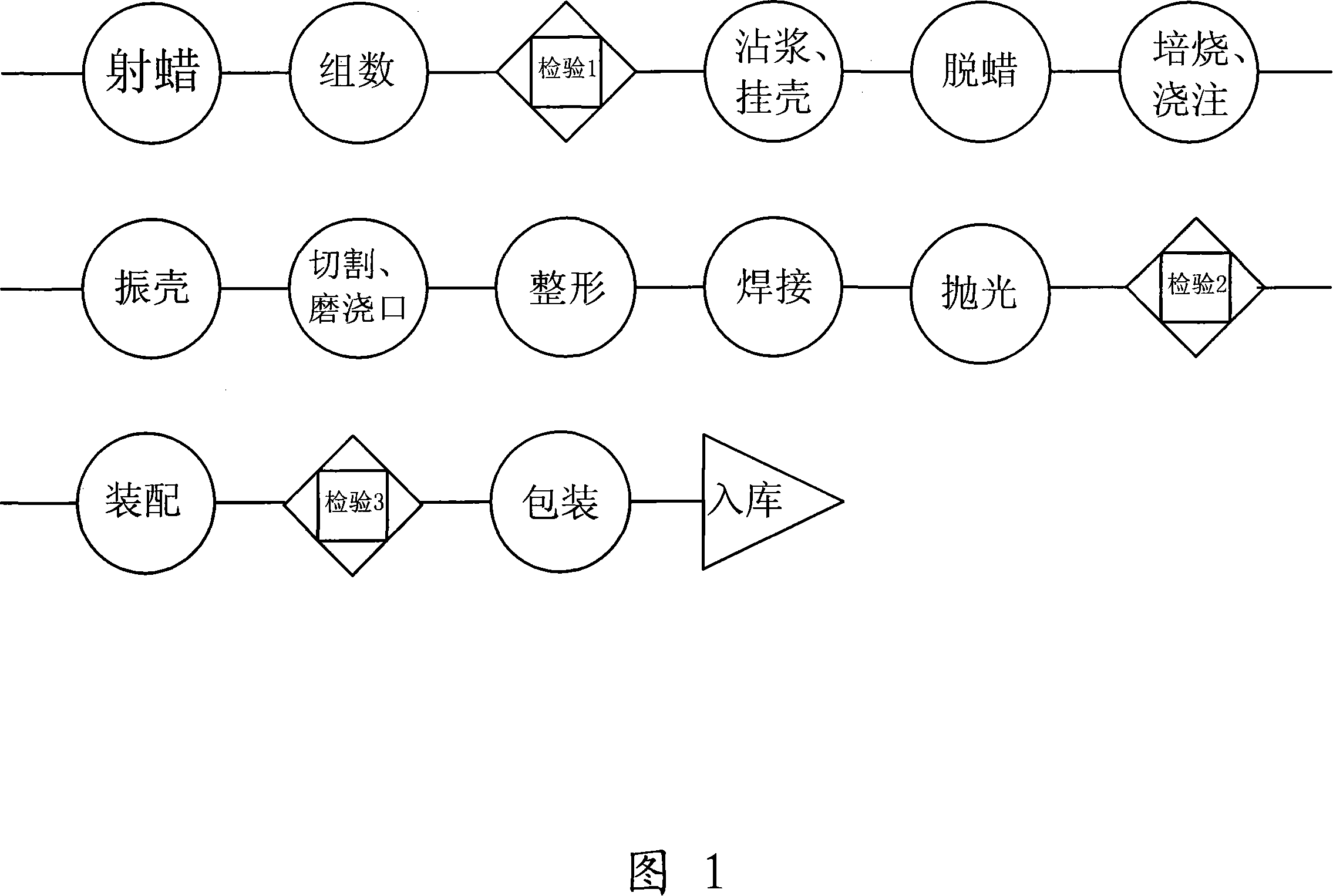

[0034] As shown in Figure 1, the manufacturing method of this stainless steel faucet is as follows:

[0035] A. Making the shell mold: inject the melted medium-temperature wax into the mold, wait for 10 seconds for the medium-temperature wax to solidify, and disassemble the mold to obtain a wax model that matches the faucet body.

[0036] In this embodiment, five wax models are produced, and a wax mold head of waxy material is also produced. The above five wax models are all bonded on the wax mold head, that is, the five wax models are grouped. . After the number of groups, the wax model is tested to check whether the size of the wax model is in place and whether there is any damage.

[0037] Then evenly dip the slurry on the outer surface of the wax model, and then stick the sand grains on the outer surface of the wax model evenly through the slurry, that is to say, carry out the shell hanging process on the outer surface of the wax model. In the present embodiment, the slur...

Embodiment 2

[0050] In this example, the solidification time of the wax model in step A is 15 seconds, and the drying time of the wax model after sticking the slurry is 5 hours and 20 minutes. The slurry is prepared by mixing silicon solution and zircon powder in a weight ratio of 1:3. . The shell mold is placed in a furnace at a temperature of 1000°C for 20 minutes of firing.

[0051] The solidification time of the stainless steel in step B is 9 minutes, and the shell mold is put into a vibration machine to vibrate, and the vibration frequency is 5 times / second, and the others are the same as in the first embodiment.

Embodiment 3

[0053] In this embodiment, the curing time of the wax model in step A is 30 seconds, and the drying time of the wax model after sticking the slurry is 6 hours. The slurry is prepared by mixing silicon solution and zircon powder in a weight ratio of 1:5. The shell mold is placed in a furnace at a temperature of 1400°C for 40 minutes of firing.

[0054] The solidification time of the stainless steel in step B is 8 minutes, and the shell mold is put into a vibrating machine to vibrate, and the vibration frequency is 4 times / second, and the others are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com