Steel strand integral bundle extrusion anchor cable guy cable

A technology of anchor cables, cables and steel strands, which is applied in the field of cables, and can solve the problems of unreliable anchoring of steel strands, high production costs, and large anchor head volume, achieving high anchoring efficiency and elongation, and improving fatigue life , good anti-corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

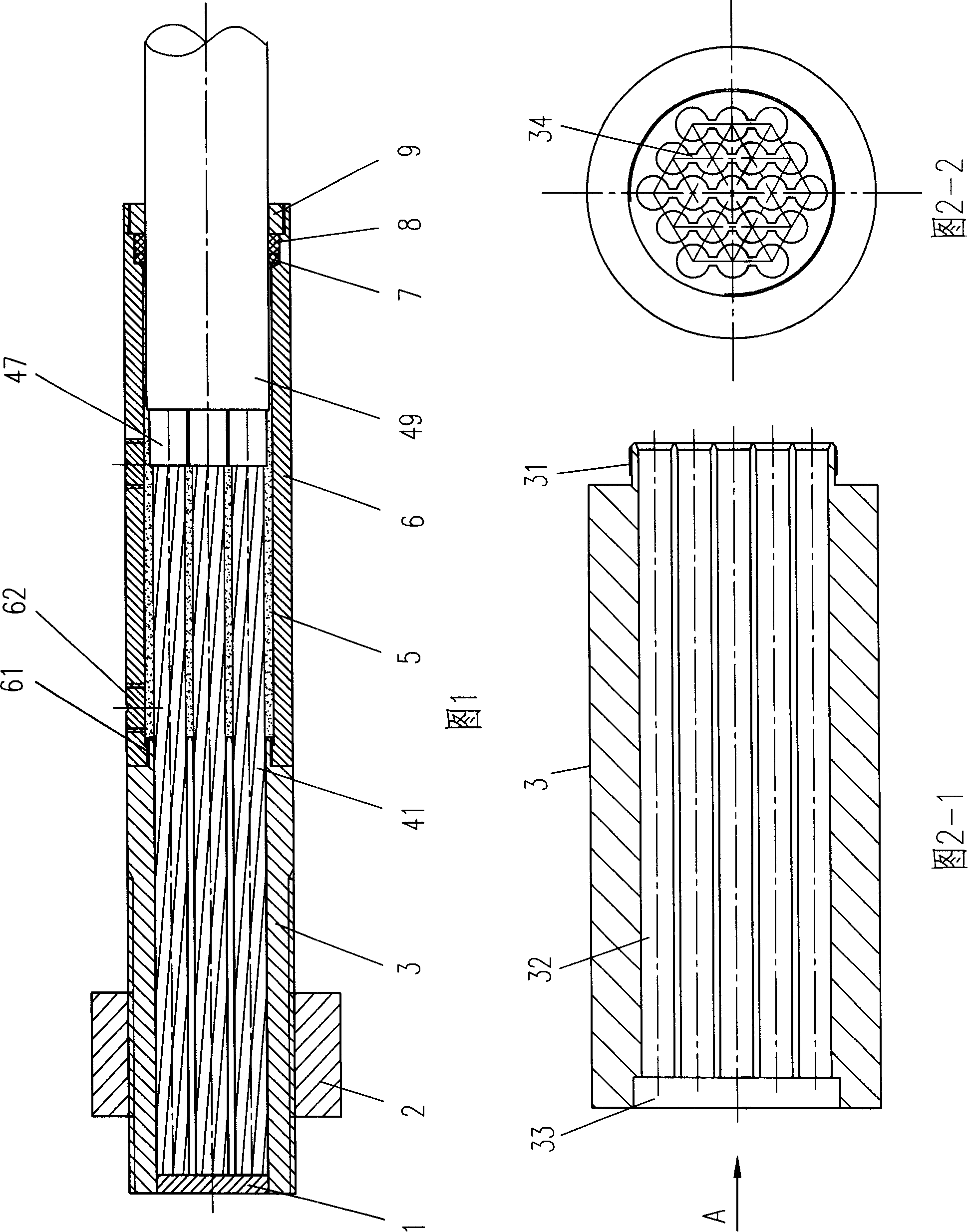

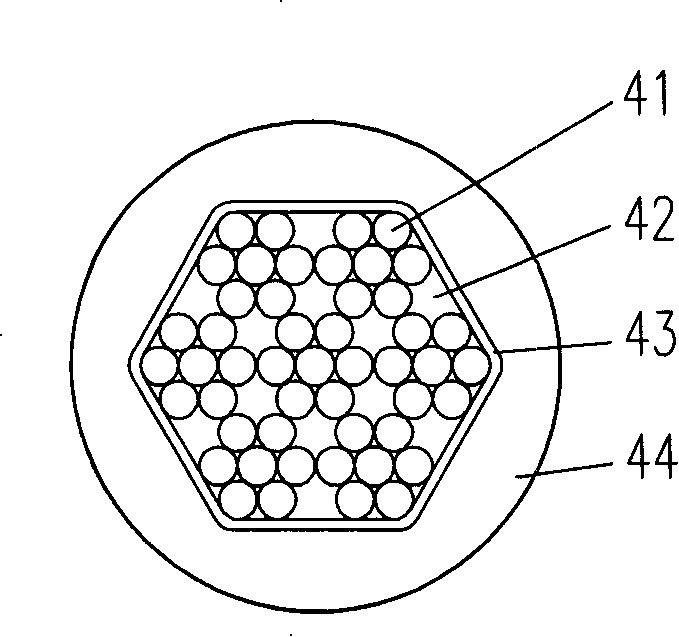

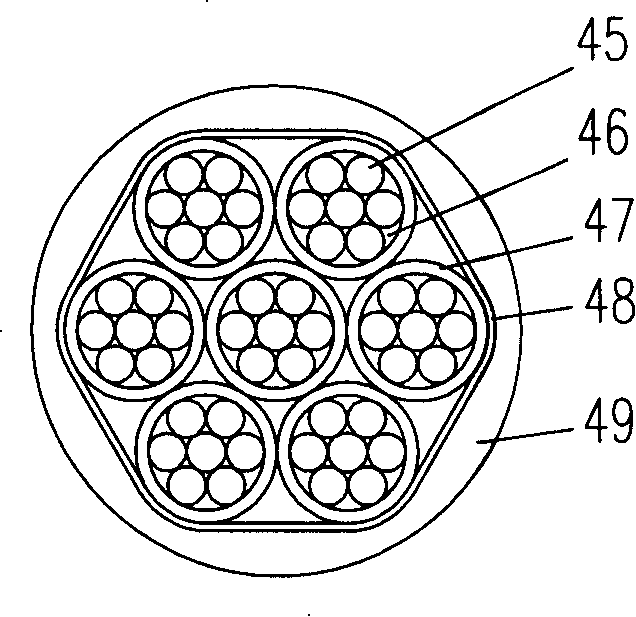

[0027] A whole bundle of steel strand extruded anchor cables stays. It consists of the finished steel strand cable body and the anchors at both ends. The anchor is divided into an anchor unit and a sealing unit. The anchor unit includes an extruded anchor sleeve 3, a nut 2, an end cover 1 and auxiliary anchor components. There is an end cover 1 at the bottom, and N (in this embodiment, N=19) steel strand embedding holes 32 equal to the number of extruded steel strands are drilled in the extruded anchor sleeve 3, and the steel strands 41 Placed in the steel strand embedding hole 32 of the extruded anchor sleeve 3 and extruded together with the extruded anchor sleeve (see Fig. 1, Fig. 2), so that each steel strand has enough extrusion Press the contact surface, after extrusion, each steel strand is evenly stressed and relatively independent; the sealing unit includes a sealing cylinder 6, a sealing ring 7, and an anti-corrosion material 5, and the extruded anchor sleeve 3 has an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com