Method for preparing organic compound single-crystal nano structure

An organic compound, single crystal nanotechnology, applied in chemical instruments and methods, single crystal growth, single crystal growth, etc., to achieve the effects of low sublimation temperature, good reproducibility, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

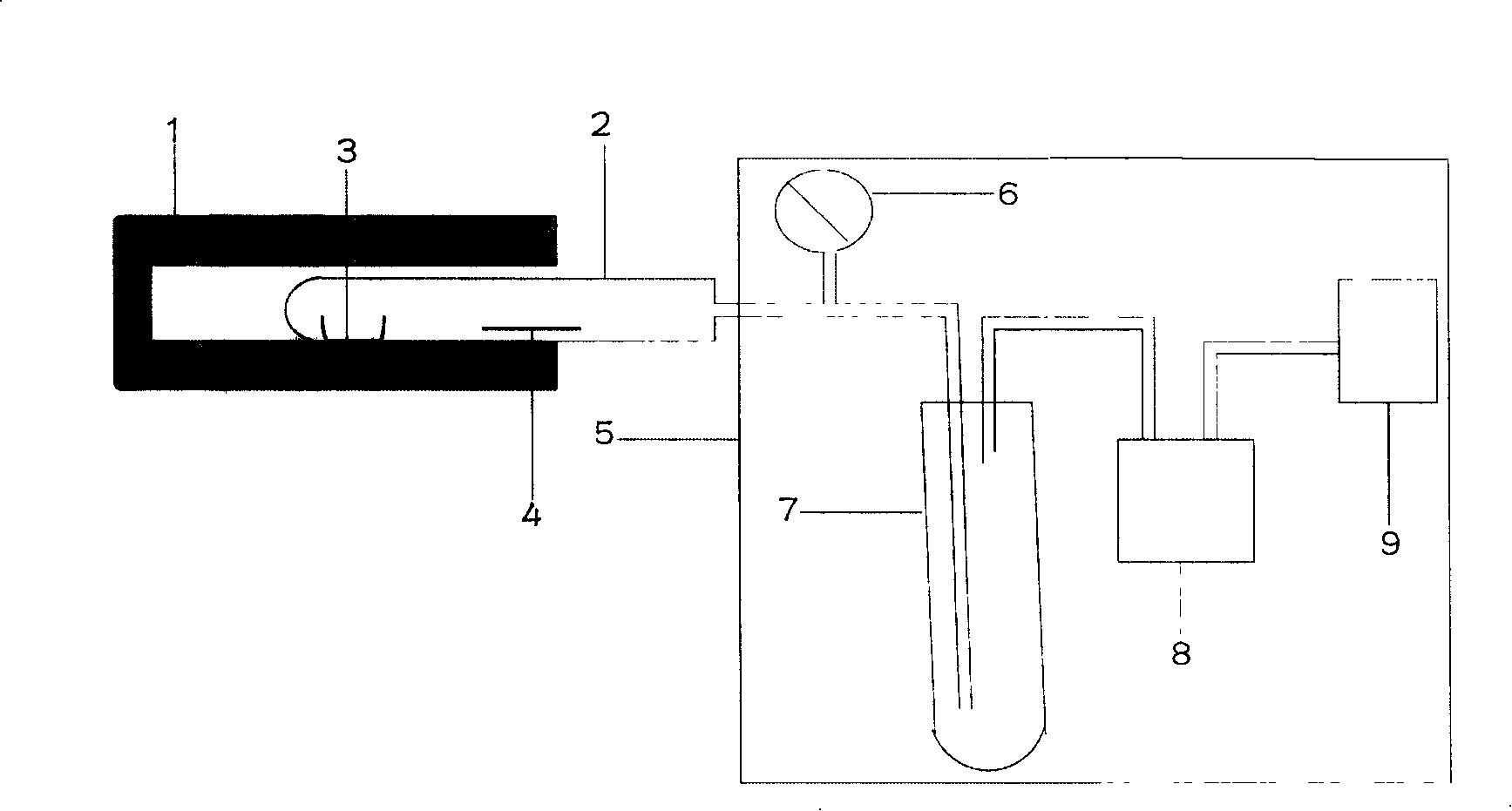

[0025] Example 1: Preparation of chlorocopper phthalocyanine single crystal nanostructure

[0026] Weigh an appropriate amount of chlorocopper phthalocyanine powder, put it into the quartz boat 3, put the quartz boat 3 on the bottom of the quartz tube 2; then put the quartz tube 2 into the central position of the horizontal tubular heating furnace 1, and put the quartz The open end of the tube 2 is connected to a vacuum system 5 . In the initial stage, first use the vacuum system to pump the pressure in the quartz tube 2 to 1 Pa, then use the horizontal tube heating furnace 1 to quickly heat the quartz boat 3 to 500-520 ° C, and keep it for 10 minutes to make the chlorine in the quartz boat 3 Sublimation of substituted copper phthalocyanine powder into chlorinated copper phthalocyanine vapor, and controlled sample growth substrate 4 (Si / SiO 2 The temperature of the sheet) is between 350-380 °C, and the vacuum pump is used to continuously work to cause the pressure difference ...

Embodiment 2

[0027] Example 2: Preparation of fluorinated copper phthalocyanine single crystal nanostructure

[0028] Weigh an appropriate amount of fluorinated copper phthalocyanine powder, put it into the quartz boat 3, put the quartz boat 3 on the bottom of the quartz tube 2; then put the quartz tube 2 into the central position of the horizontal tubular heating furnace 1, and put the quartz The open end of the tube 2 is connected to a vacuum system 5 . In the initial stage, first use the vacuum system to pump the pressure in the quartz tube 2 to 1 Pa, then use the horizontal tube heating furnace 1 to rapidly heat the quartz boat 3 to 450-470 ° C, and keep it for 5 minutes to make the fluorine in the quartz boat 3 Copper phthalocyanine powder is sublimated into fluorinated copper phthalocyanine vapor, and the temperature of the sample growth substrate 4 (silicon wafer) is controlled between 280-330°C, and vacuum pumps are used to continuously work to form fluorinated copper phthalocyanin...

Embodiment 3

[0030] Embodiment 3: Preparation of copper phthalocyanine single crystal nanostructure

[0031] Weigh an appropriate amount of copper phthalocyanine powder, put it into the quartz boat 3, put the quartz boat 3 on the bottom of the quartz tube 2; then put the quartz tube 2 into the central position of the horizontal tubular heating furnace 1, and place the quartz tube 2 The open end of is connected with vacuum system 5. At the initial stage, first use the vacuum system to pump the pressure in the quartz tube 2 to 1 Pa, then use the horizontal tube heating furnace 1 to rapidly heat the quartz boat 3 to 400-420 ° C, and keep it for 10 minutes to make the copper in the quartz boat 3 The phthalocyanine powder is sublimated into copper phthalocyanine vapor, and the temperature of the sample growth substrate 4 is controlled between 250-280°C, and the continuous operation of the vacuum pump is used to cause the pressure difference of the copper phthalocyanine vapor in different temper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com