Method for preparing dehydrolinalyl acetate from dehydrolinalool

A technology for dehydrolinalool and linalyl ester, applied in the field of preparation of dehydrolinalyl acetate, can solve the problems of lack of industrial application value, complicated separation process, low catalyst activity, etc. The effect of ideal selectivity, short reaction time and high reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

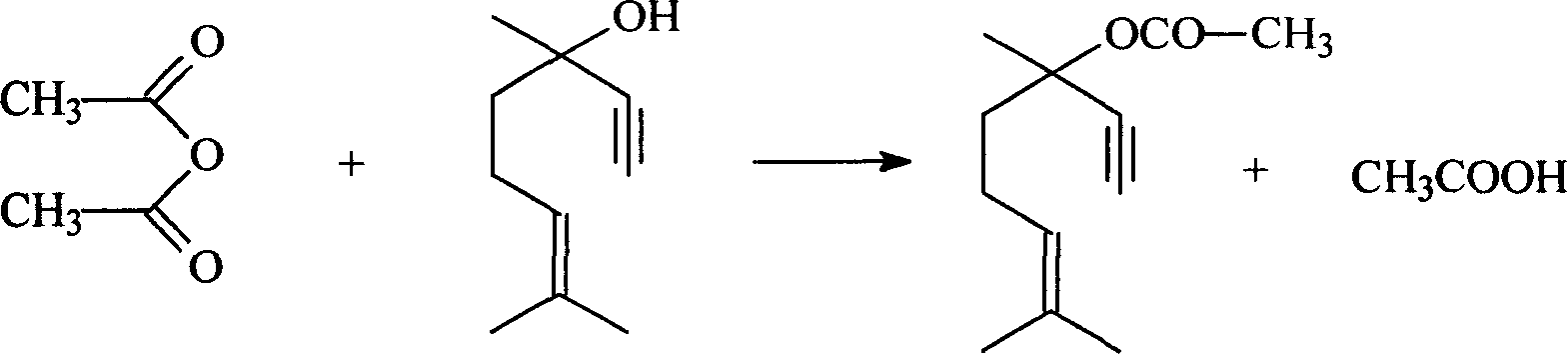

Image

Examples

Embodiment 1~11

[0018] A 500ml three-necked flask with a stirring device is placed in a water bath, 152g of dehydrolinalool is added, nitrogen is purged for 20min, the temperature is raised to the reaction temperature with stirring, and acetic anhydride is dropped in according to the required molar ratio, and the The required amount of catalyst sulfosalicylic acid starts the reaction and is maintained for the required reaction time to complete the reaction. The product is cooled, washed with water, and statically layered to separate the oil and water phases until the oil phase material is neutral, and the oil phase material is taken to obtain the dehydrolinalyl acetate product.

[0019] The specific reaction conditions of each embodiment are shown in Table 1, and the reaction results are shown in Table 2.

[0020] Table 1.

[0021] temperature reflex

(℃)

Reaction time

(min)

The amount of catalyst

(wt%)

Raw material molar ratio

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com