Lifting type handcart

A lifting and trolley technology, applied in the directions of lifting frames, wheels, lifting devices, etc., can solve the problems of sliding, difficult, and inconvenient clamping of the trolley, so as to achieve convenient positioning and clamping of workpieces, and safe adjustment and disassembly. The effect of easy lifting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

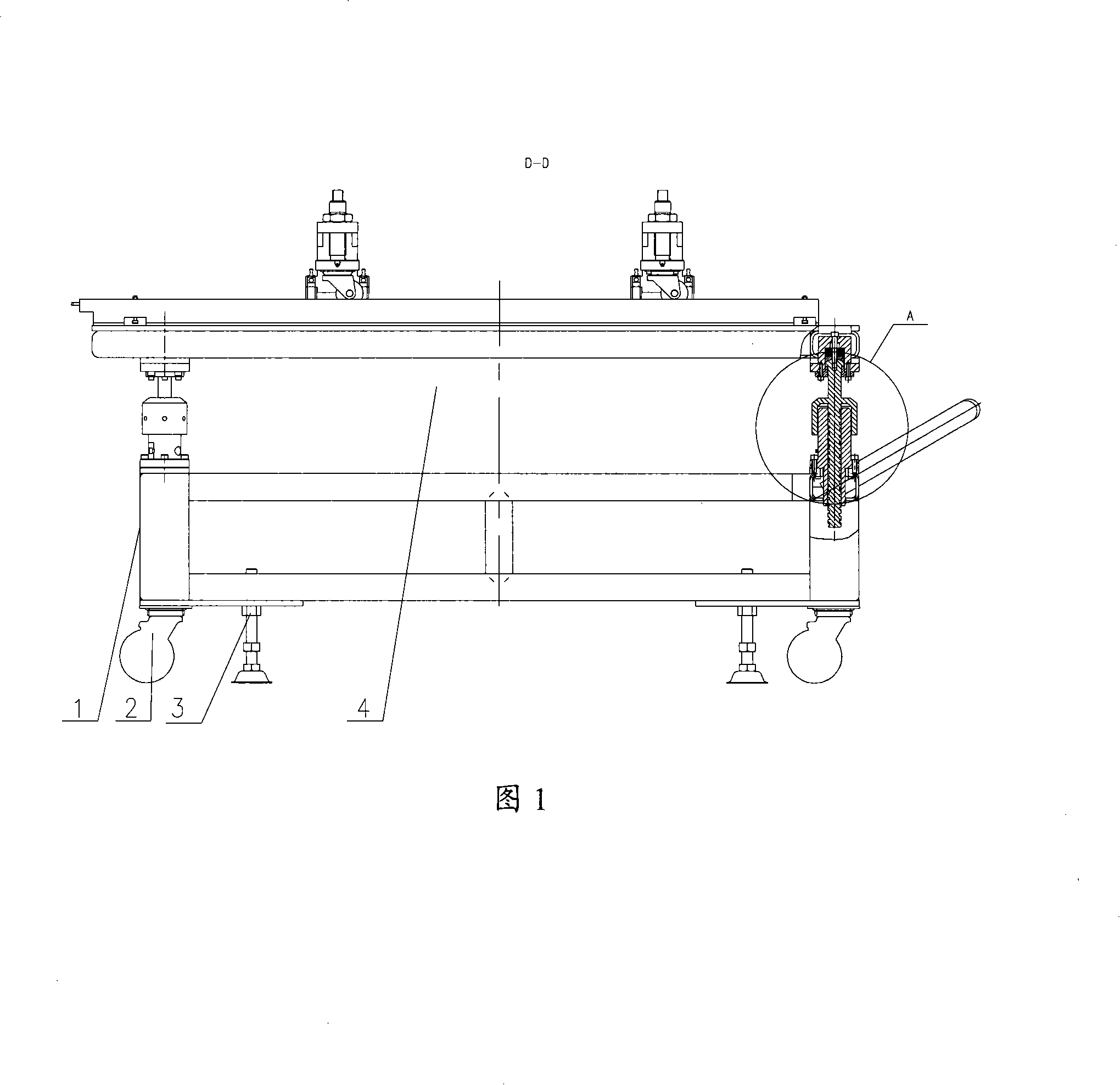

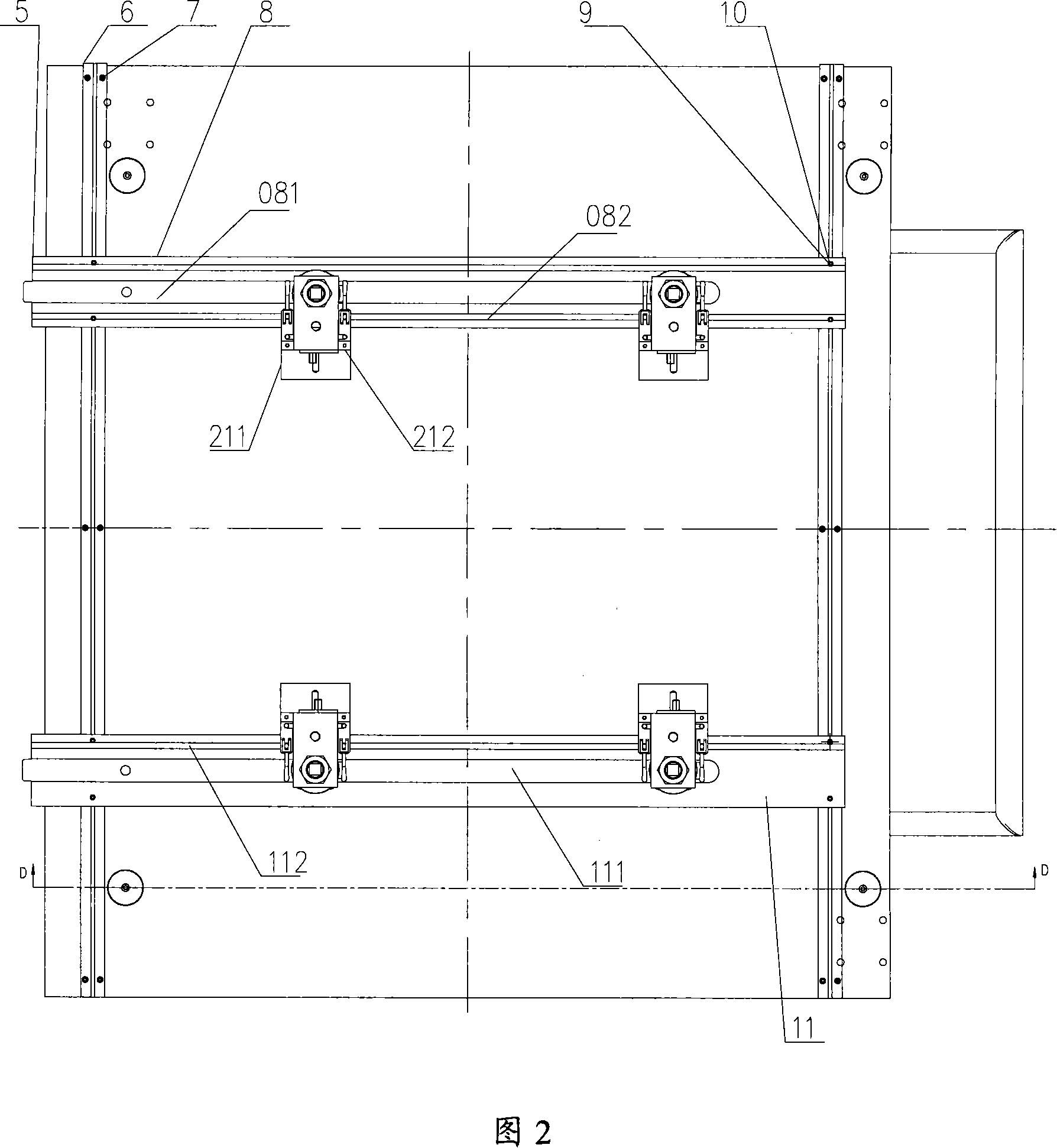

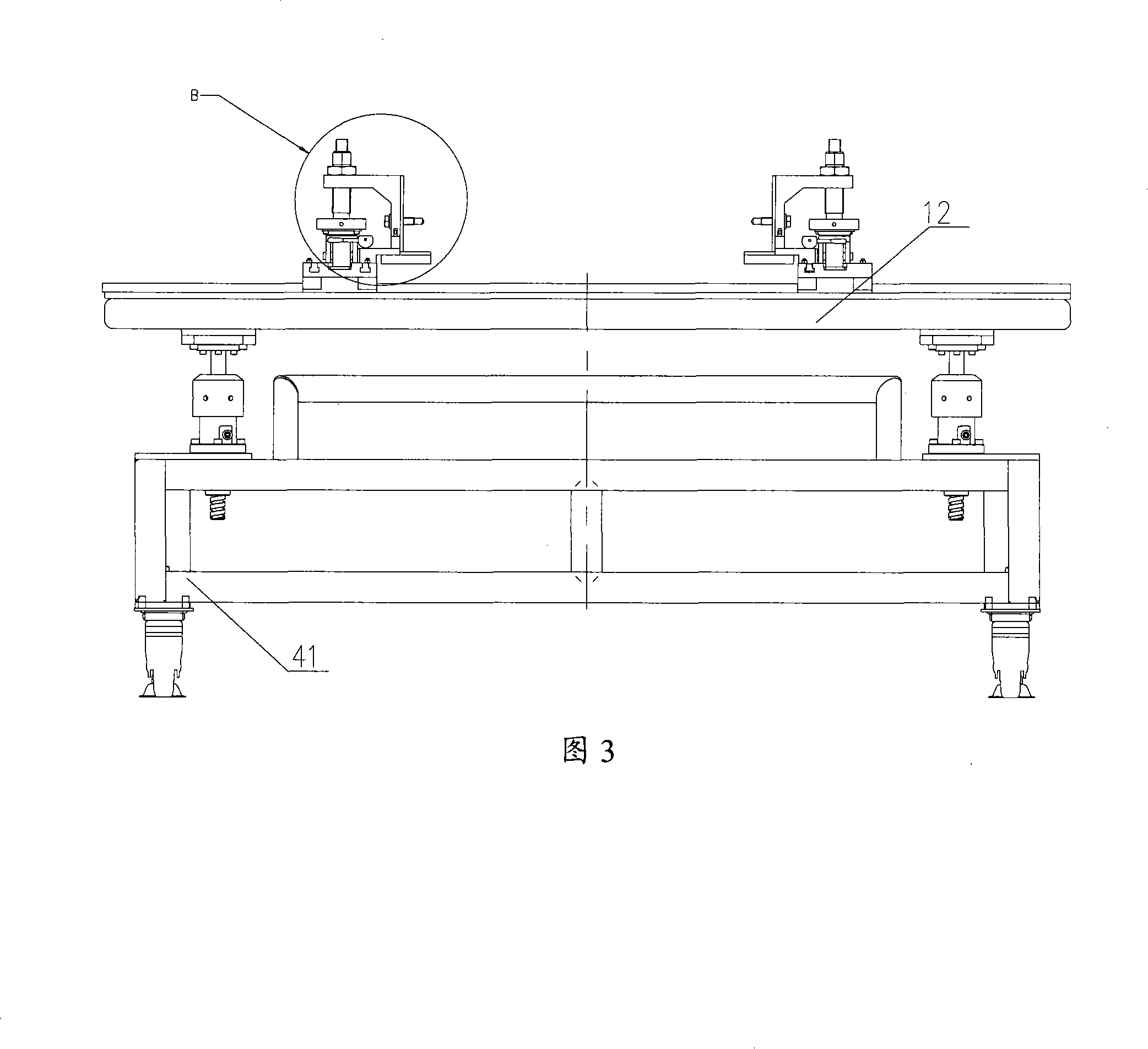

[0069] As shown in Figures 1 to 3, the present invention provides an elevating trolley, which includes a base mechanism and an upper bracket mechanism, and also includes several lifting and locking mechanisms connecting the base mechanism and the upper bracket mechanism, and is arranged on the Several workpiece lifting and locking positioning mechanisms on the upper bracket mechanism;

[0070] The base mechanism includes several casters 2 and several caster adjustment blocks 3;

[0071] The caster 2 is installed on the base 1 through a number of hexagon socket head cap screws 41, and the caster adjustment block 3 is installed on the base 1 through threads;

[0072] The upper bracket mechanism includes two guide rails 6 arranged in parallel, and also includes several sliding guide rails 5;

[0073] The guide rail 6 is fixed on the upper bracket 4 by several hexagonal cylinder head screws 7;

[0074] The sliding guide rail 5 is installed on the guide rail 6 through the trapezo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com