Heat exchanger for cold rolling mill sulfuric acid refining on-line

A cold rolling mill acid and heat exchanger technology, applied in the direction of heat exchanger types, direct contact heat exchangers, chemical instruments and methods, etc., can solve problems such as Venturi tube and circulation pipeline blockage, and avoid circulation The effect of pump damage, simple structure and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

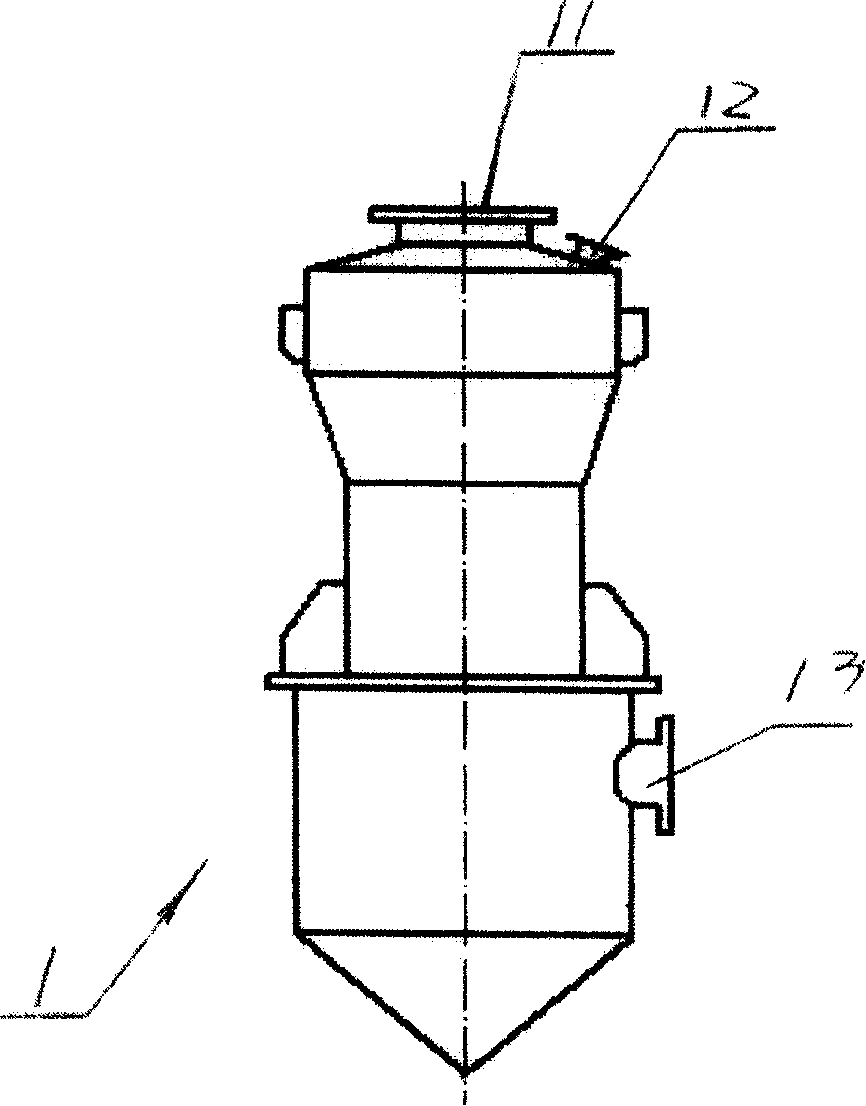

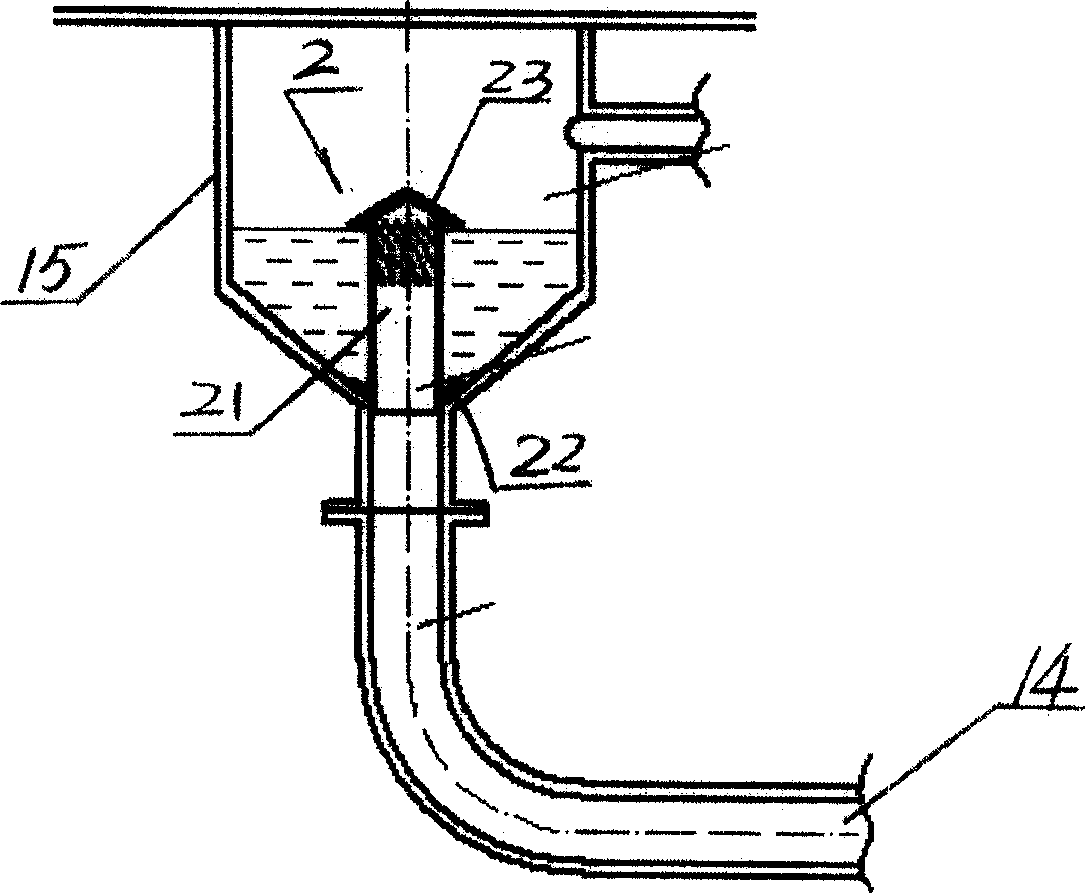

[0011] see figure 1 and figure 2 , these two drawings show the overall structure of the appearance of an embodiment of the heat exchanger used in the pickling line of the cold rolling mill proposed by the present invention. As can be seen from the figure, the heat exchanger comprises two parts, a Venturi device 1 and an acid-resistant filter device 2, wherein a Venturi tube 15 (attached) is arranged in the Venturi device 1 figure 2 Only the structure of the bottom area of the Venturi tube 15 is given in the figure), a high-temperature furnace gas inlet 11 and a waste acid inlet 12 are provided at its upper end, and a high-temperature furnace gas outlet 13 is provided at its lower area, and at the bottom of the Venturi tube 15 A waste acid output pipeline 14 is installed at the bottom. The filter device 2 is installed between the waste acid output pipeline 14 and the bottom of the venturi tube 15 . The filter device 2 includes a filter element 21, which is basically a lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com