Device and method for testing and standardizing performance of macrotype over-loading operation equipment

A forging manipulator and calibration device technology, applied in the field of machinery, can solve the problems of no large-scale heavy-duty operating equipment performance test device and method, late start, etc., to achieve rapid performance test and detection, easy control, and fast response Effect

Inactive Publication Date: 2010-11-24

SHANGHAI JIAOTONG UNIV

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Domestic research on large-scale forging manipulators and other heavy-duty operating equipment started relatively late, so through searching, no relevant devices and methods for performance testing and calibration of large-scale heavy-duty operating equipment were found

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

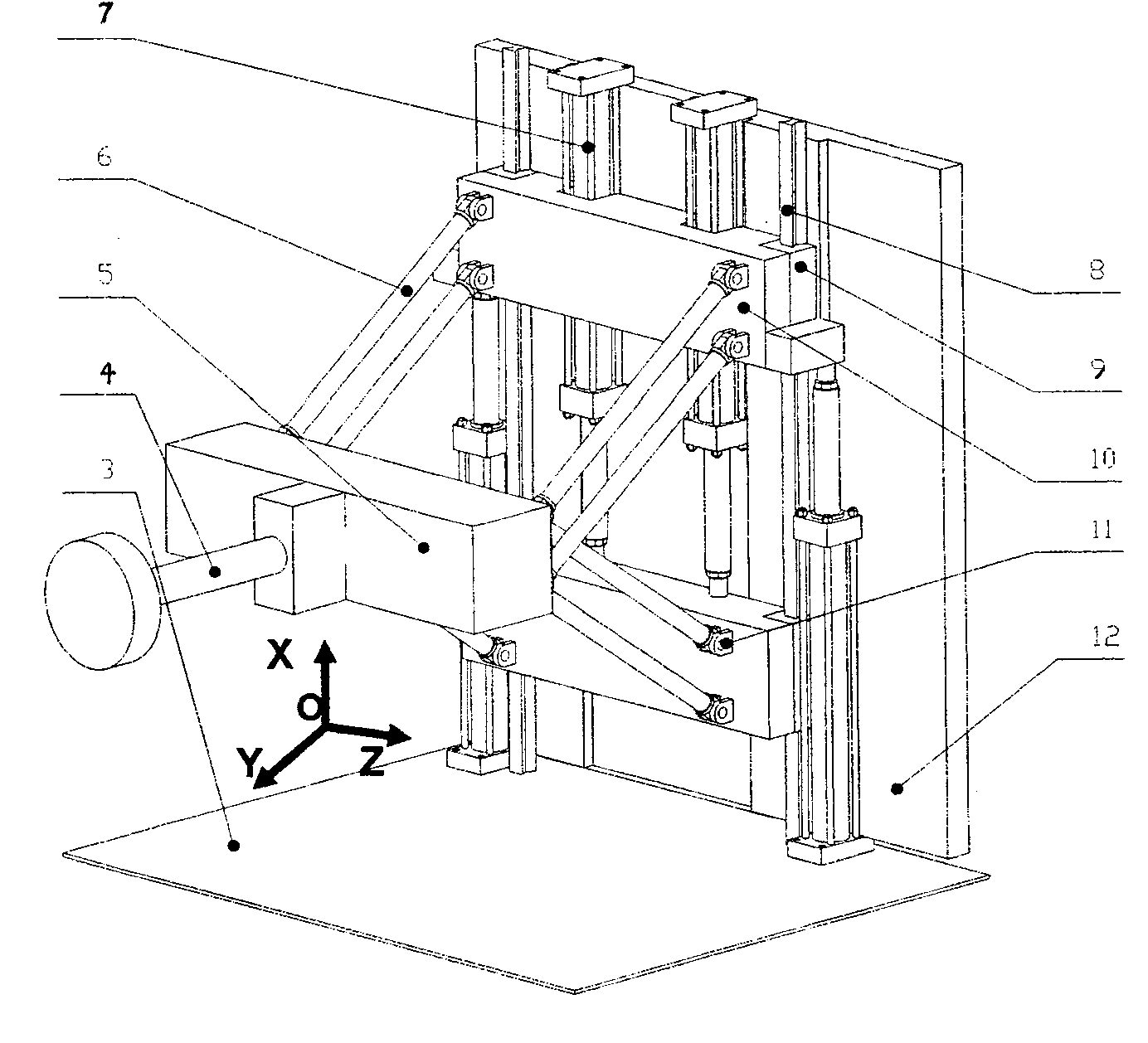

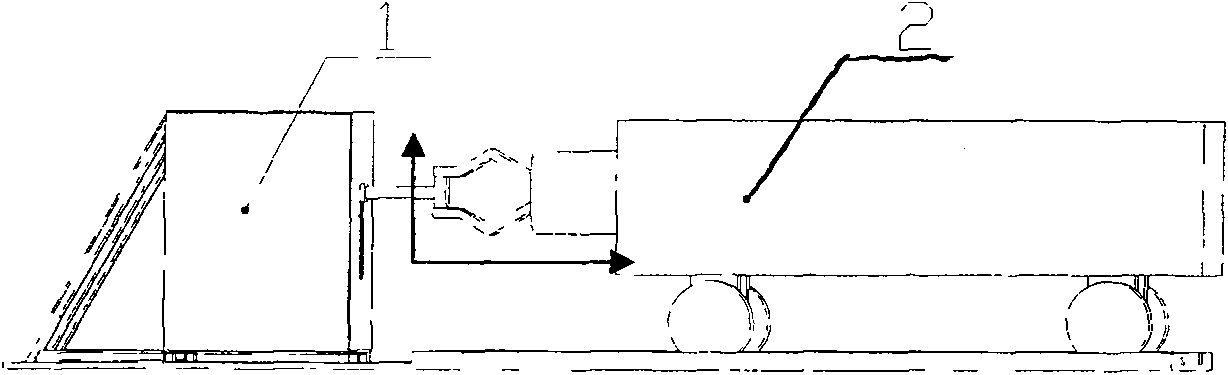

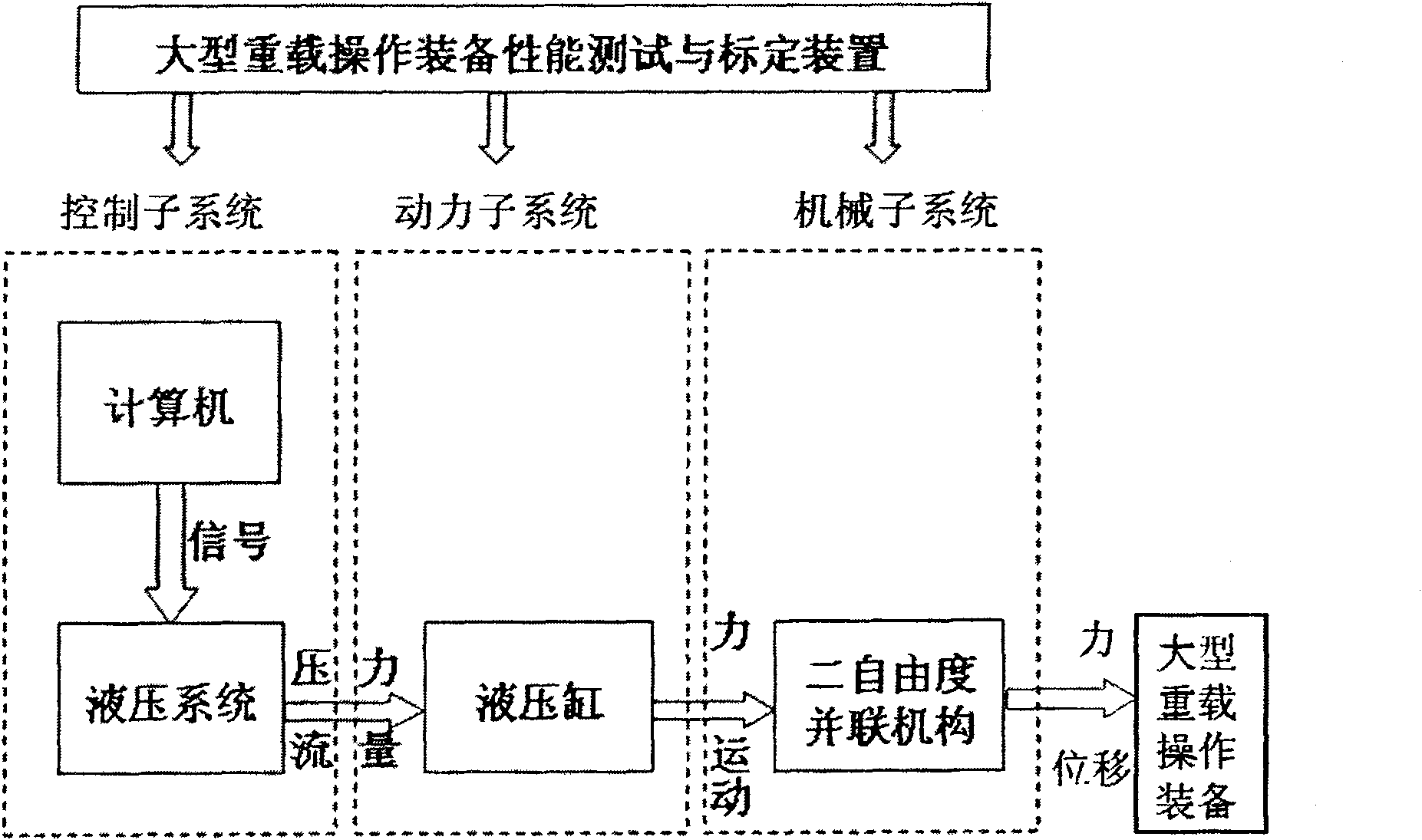

The invention relates to a performance test and calibration device and method for large-scale heavy-load operating equipment in the mechanical technology field. The device comprises a control subsystem, a power subsystem, and a mechanical subsystem, wherein the mechanical subsystem is a two-freedom-degree motion parallel mechanism, the control subsystem consists of a computer and a hydraulic system, and the power subsystem consists of four hydraulic cylinders. The invention simulates the operating condition of large-scale heavy-load operating equipment through the performance test and calibration device of large-scale heavy-load operating equipment and a computer simulation analysis method, and then butts with the large-scale heavy-load operating equipment or the model of the large-scale heavy-load operating equipment, thereby testing the performance of the equipment, calibrating the parameters of the equipment and testing the capacity of the equipment. The invention realizes the semi-physical simulation and performance test and calibration of large-scale forging operating equipment in a way of combining virtual and real situations, thereby greatly boosting the developing process of large-scale heavy-load operating equipment.

Description

Forging Manipulator Performance Test and Calibration Device and Its Test and Realization Method technical field The invention relates to a device and method in the field of mechanical technology, in particular to a performance testing and calibration device for a forging manipulator and a testing method thereof, especially for large forging manipulators. Background technique With the continuous development of my country's manufacturing industry, the importance of large-scale equipment, especially large-scale heavy-duty operating equipment, has become more and more obvious. For example, large-scale forging manipulators have obvious effects in improving the production efficiency of the iron and steel industry, but my country has not yet The core technology of large-scale heavy-duty operating equipment with independent intellectual property rights, so the development of large-scale heavy-duty operating equipment with superior performance has become an important topic. However, ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): G01M19/00G01M99/00

Inventor 杜正春林忠钦高峰姚振强张普

Owner SHANGHAI JIAOTONG UNIV

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com