Outer cashmere composite yarn and manufacturing method thereof

A technology for wrapping cashmere and yarn, which is applied in the field of spinning, and can solve the problems of short length, poor hand feeling, easy pilling and hair loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

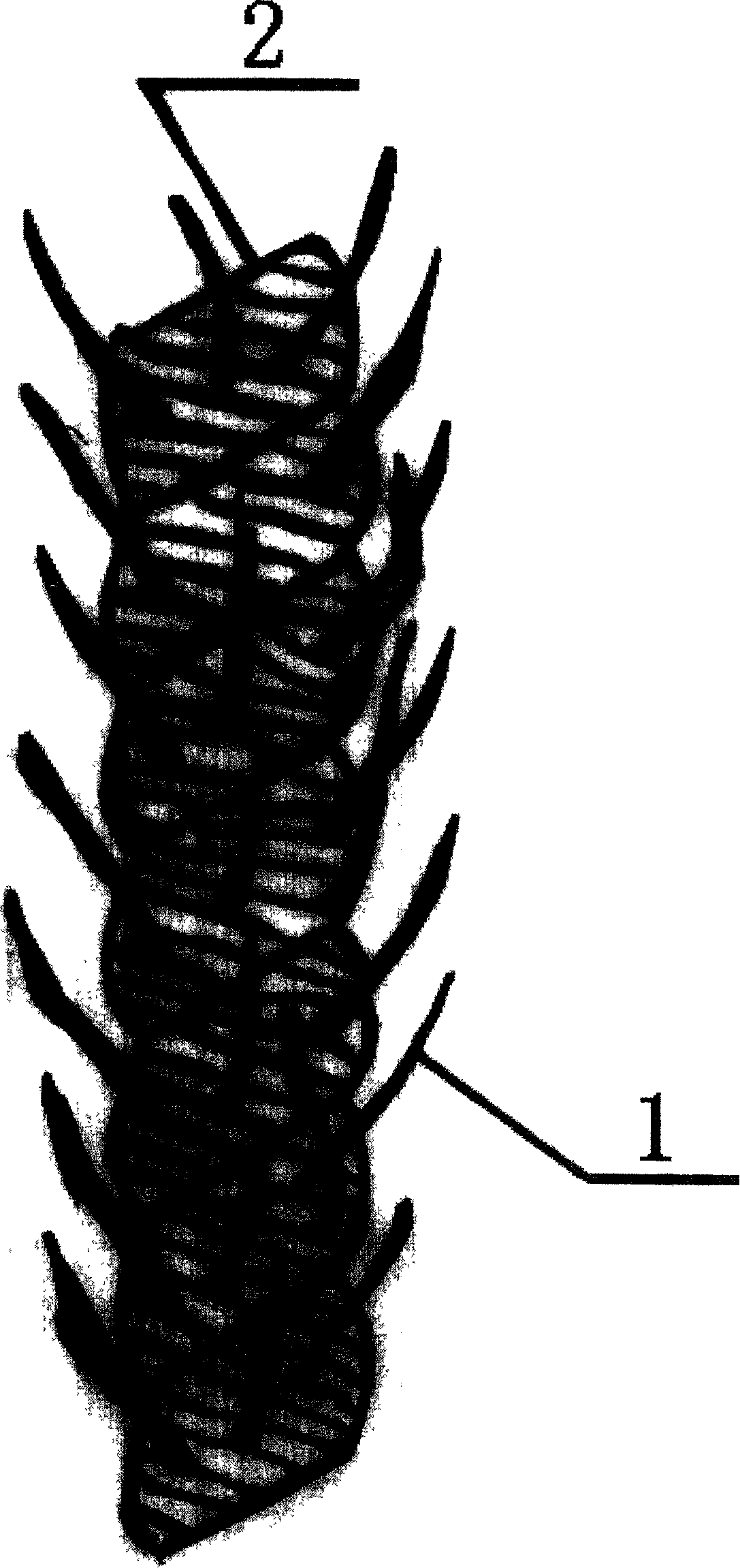

[0014] The yarn of the present invention is a kind of blank product in textiles, which is composed of cashmere and more than one kind of fiber. The combination method is that the cashmere fiber 1 is evenly distributed and wrapped on the surface of the core fiber 2 , one end of which is combined with the core fiber 2, crossed and twisted together to form a trunk line, and is tightly held by the combined trunk yarn, so that the cashmere fiber 1 does not slide relative to the core fiber 2 on the yarn, And then ensure that the cashmere on the clothing products does not produce or less pilling, hair loss, and felting.

[0015] The mechanism of action is that all the fibers that make up the yarn are superimposed into a large strength state after being slivered and twisted, but most of the cashmere fibers do not participate in the superimposed resultant force, so Although different fibers have different quality and different shrinkage rates that restrict the overall strength of the y...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com