Flexural oscillation testing machine for metal flexible pipe

A metal hose, bending and swinging technology, applied in the direction of applying repeated force/pulsation force to test the strength of materials, can solve the problems of deviation, instability, and low test efficiency of the motion track, and achieve the satisfaction of the motion track, improve accuracy, Experiment with smooth effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

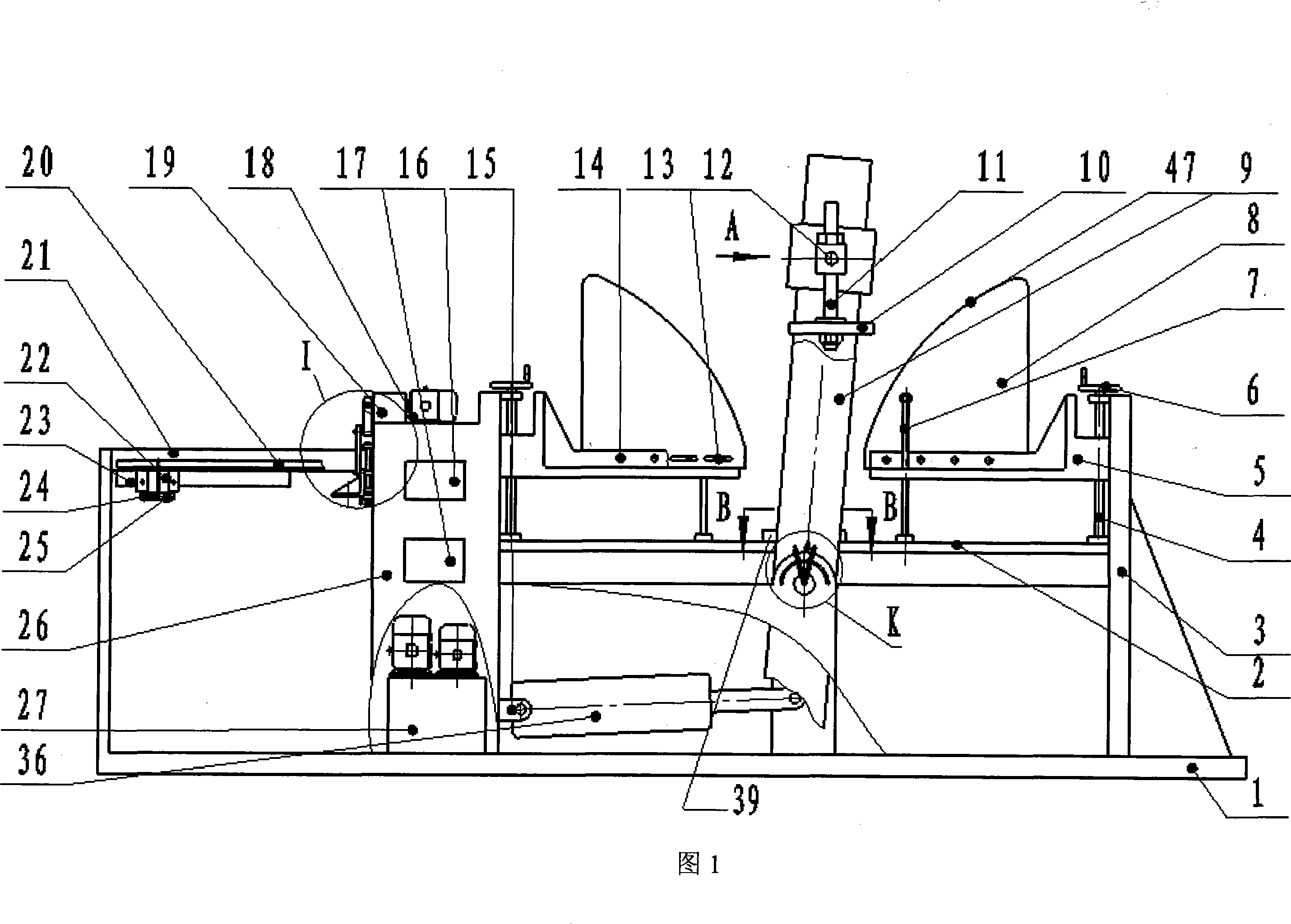

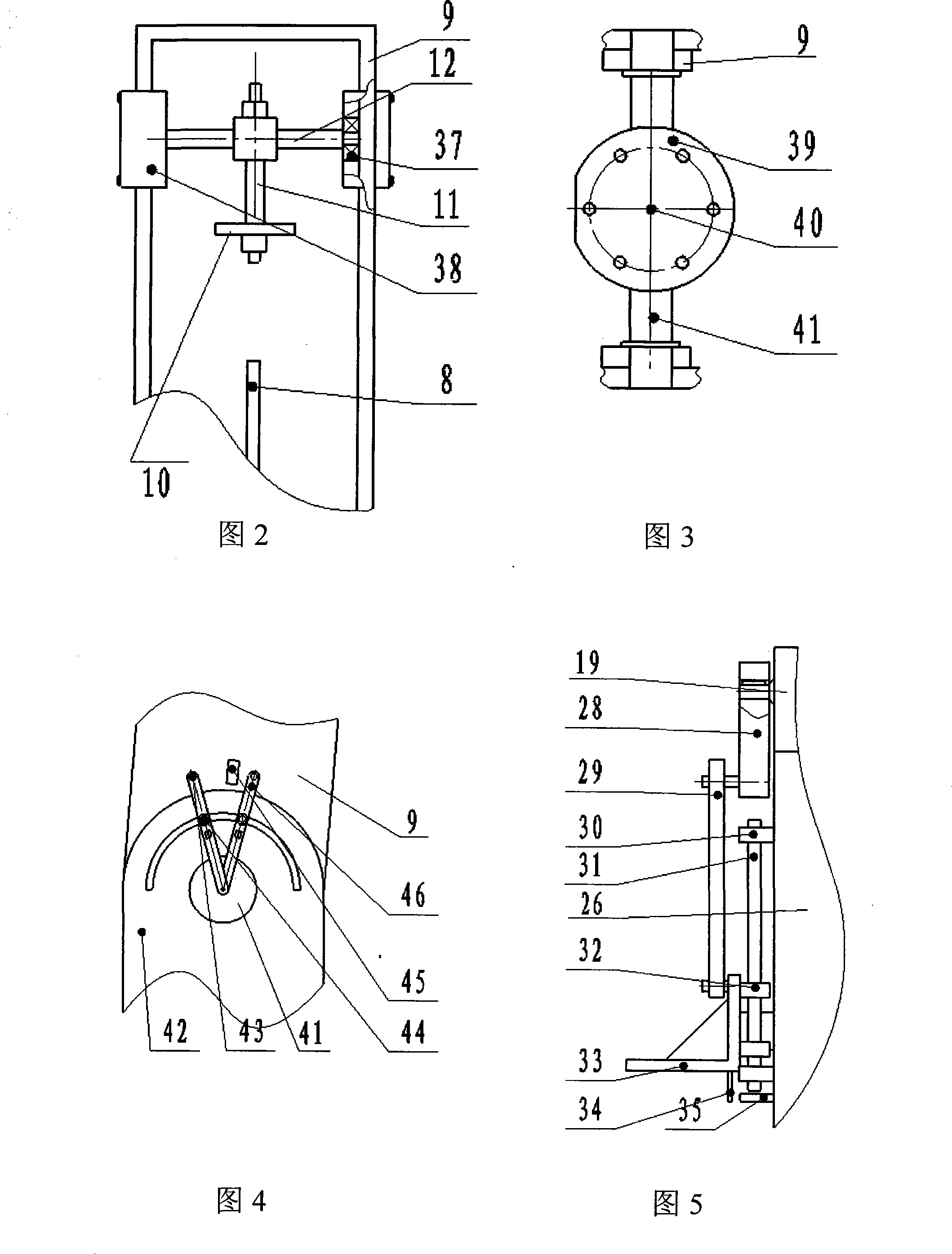

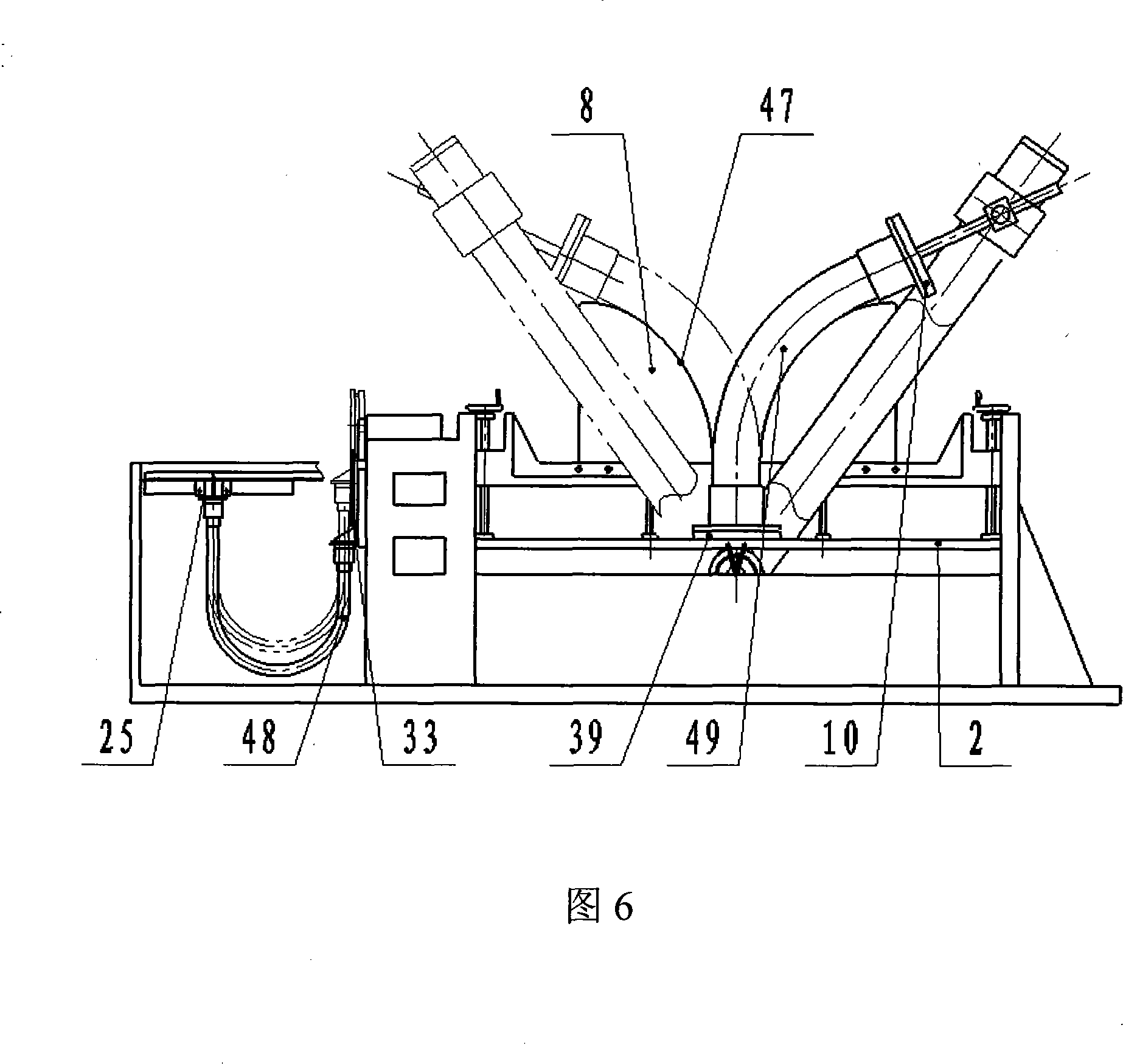

[0034] As shown in Figures 1 to 4, 1 in the figure is the frame, 26 is the control cabinet, 17 is the electrical control unit, and 16 is the display unit. A control cabinet 26 is installed on the frame 1, and a control cabinet 26 is installed on the lower part of the control cabinet. The two-unit hydraulic pump station 27 has an electrical control unit 17 and a display unit 16 in the middle, and the two-unit hydraulic pump station is connected to the transmission cylinder 36 through the hydraulic cylinder seat 15; the two ends of the load beam 2 are respectively connected to the fixed columns of the frame 1 3 and the control cabinet 26, a fixed pressure base 39 with a pressure hole 40 is fixed in the middle of the load beam 2. Lifting platform 5 equipped with bending limit plate 8 is respectively arranged at the two ends of loading beam 2 , and lifting platform 5 is fixed on loading beam 2 through lifting adjustment lead screw 4 and support screw 7 equipped with hand wheel 6 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com