High-wetness frostless cool house

A cold storage and high-humidity technology, applied in the field of cold storage, can solve problems such as inconvenient adjustment and insufficient capacity, and achieve the effects of convenient adjustment, good cooling effect, and reduced energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

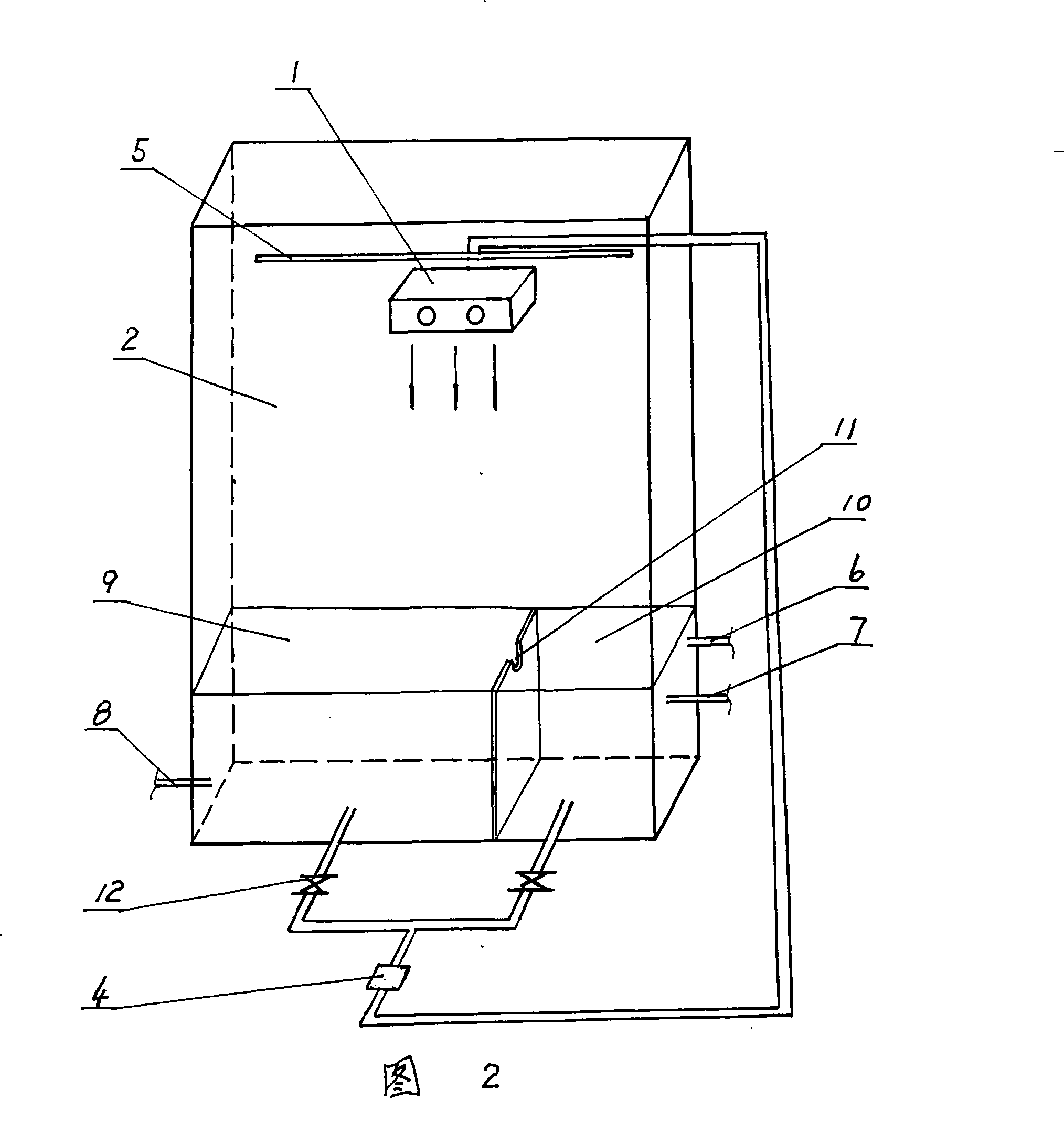

[0011] Accompanying drawing 1 is an embodiment of the present invention, and it comprises refrigeration compressor unit, air cooler 1, and refrigeration compressor unit communicates with air cooler 1, and air cooler 1 is arranged in cold storage 2, also includes liquid reservoir 3, circulation pump 4. Spray pipe 5, etc. The liquid storage pool 3 is arranged at the bottom of the cold storage 2, and a low-freezing-point solution is placed in the liquid storage pool 3. The liquid storage pool 3 is provided with a feeding port 6, a liquid filling port 7 and a liquid discharge port 8 leading to the outside of the cold storage room 2, and the circulation The liquid inlet of the pump 4 stretches into the low freezing point solution in the liquid storage tank 3 through the pipeline, and the liquid outlet of the circulation pump 4 is arranged on the upper side of the cooling fan 1 in the cold storage 2 through the pipeline, and can control the cooling fan 1 and the cold storage. 2 The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com