Method for producing diene sterone

A technology of diensterone and diene, which is applied in the field of preparation of diensterone, can solve the problems of difficult reuse of E component, low yield, high cost, etc., so as to avoid difficulty in product purification, high reaction yield, and reduce The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Preparation of pregna-5,17(20)-diene-3,16-diol:

[0024] In a 250mL three-necked flask, 200mL of absolute ethanol, pregna-16,17-epoxy-5-en-3-hydroxyl-20-one (10.0g, 30mmol), sodium hydroxide (2.0g, 50mmol) were added, Stir, heat up to 78°C to dissolve, then slowly add hydrazine hydrate (20.0g, 320mmol) with a mass percentage of 80% into the system dropwise at 80°C under reflux, the dropwise addition is completed in about 30 minutes, and then the system continues under reflux at 80°C Stir the reaction for 2 hours until the reaction is complete (TLC detection), then pour the mixture in the system into 1000mL of water, a large amount of white solid is precipitated, filter, the filter cake is fully washed with water until neutral, and dried to obtain pregna-5,17(20) - Diene-3,16-diol Z&E (9g, yield: 90%, Z≥E)

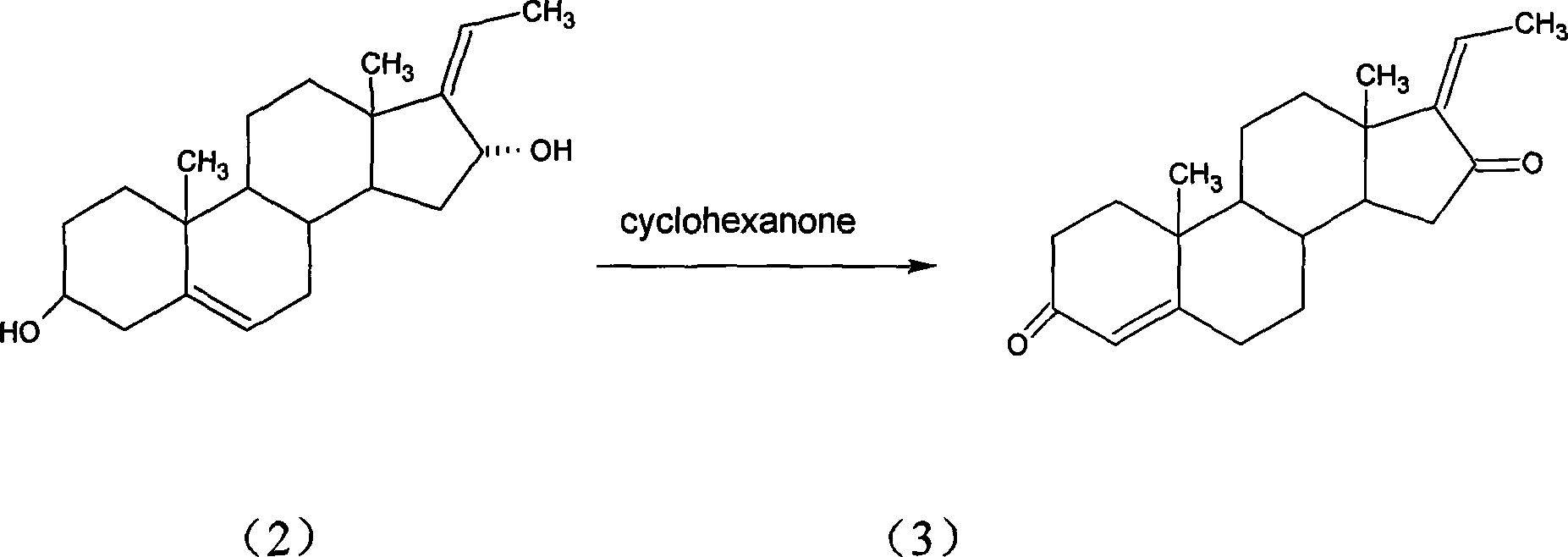

[0025] Preparation of pregna-4,17(20)-diene-3,16-dione:

[0026] Add 800 mL of toluene, cyclohexanone (80 g, 816 mmol), pregna-5,17(20)-diene-3,16-diol (10 g, 31 m...

Embodiment 2

[0029] Using the same method as in Example 1, wherein the catalyst is potassium carbonate (3 g, 22 mmol), the reaction temperature in step (1) is 0° C., and the reaction time is 20 hours.

[0030] Pregna-4,17(20)-diene-3,16-dione Z&E (8.9 g, yield: 89%, Z≧E) was obtained.

Embodiment 3

[0032] Adopt the method identical with embodiment 1, wherein, catalyst adopts sodium phosphate, add-on is (4g, 24mmol), the reaction temperature of step (1) is 50 ℃, and the reaction time is 10 hours.

[0033] Pregna-4,17(20)-diene-3,16-dione Z&E (8.8 g, yield: 88%, Z≧E) was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com