Production technology for artichoke can

A production process and artichoke technology, applied in the field of canned artichoke products and their production processes, can solve the problems that the processing scale is difficult to adapt to the market demand, the key technology has not been completely solved, the time and season of fresh fruits are limited, etc. The effect of material science and disease prevention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

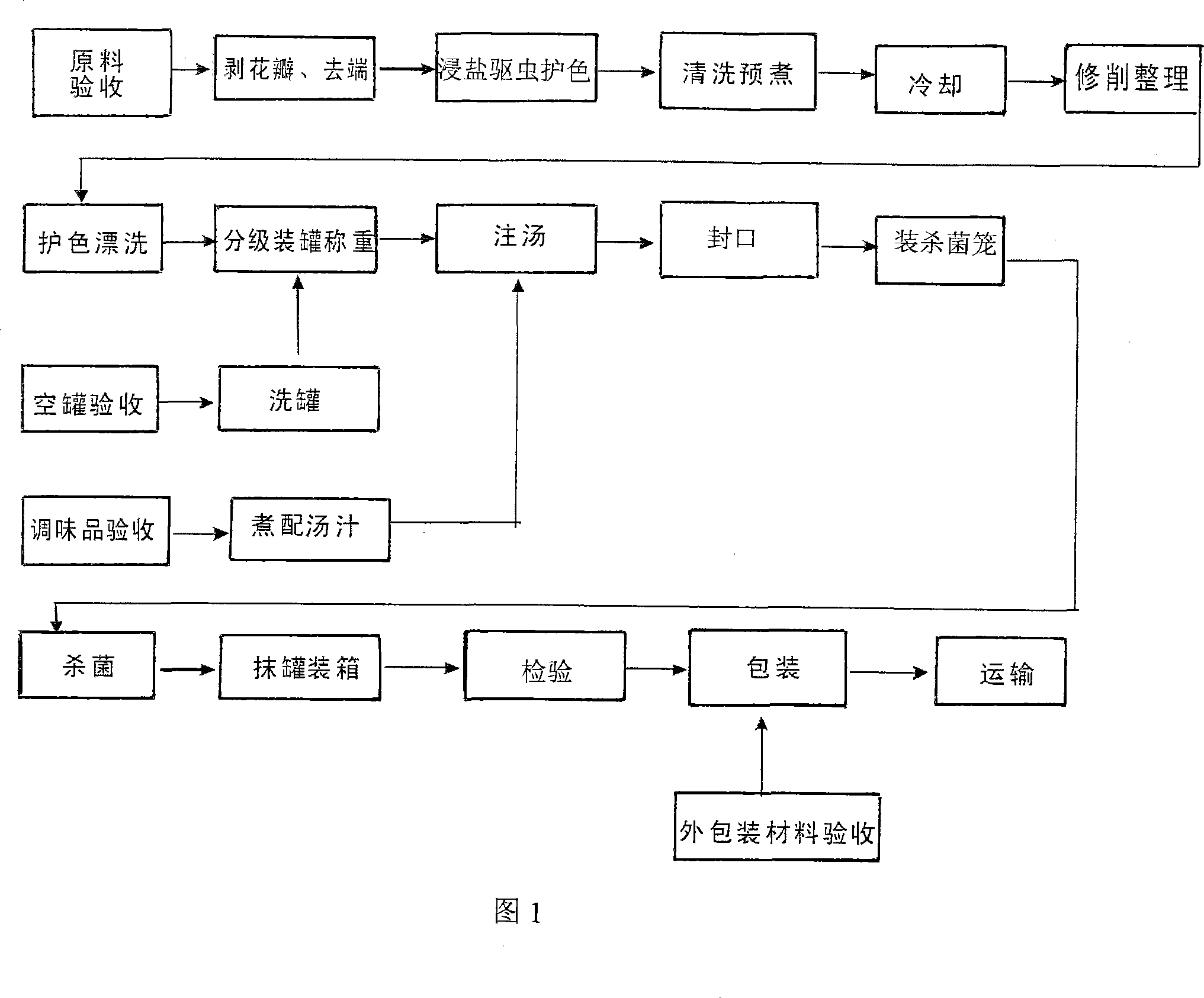

[0025] The canned artichoke of the present invention is made of artichoke buds, the raw materials are checked and accepted, selected and arranged, and the production process is as follows:

[0026] 1. Peel the petals and remove the ends: Remove the older petals with larger thick fibers one by one from the artichoke flower. During the process of removing the petals, pay attention to removing the petals one by one, and it is not allowed to pull several pieces to avoid tearing off the flower flesh; Then cut off the artichoke stalk head and leave 0.5-0.7cm of stalk meat, and then cut off the petal tail measuring from the end of the receptacle to 3.0cm.

[0027] 2. Soak in salt water to repel insects and protect color: put the artichokes with petals removed one by one into a stainless steel container with 10% salt solution to soak in salt water to repel insects and protect color. The salt soaking time is 30 minutes; the color protection solution in this step 100kg of water, 10kg of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com