Method for preparing carthamin yellow carthamus B and application thereof

A technology of safflower yellow pigment and safflower, which is applied to medical preparations, pharmaceutical formulations, plant raw materials and other directions containing active ingredients, can solve the problems of large dead adsorption, few reusable times of polyamide, and difficult elution. , to achieve the effect of simple processing of fillers, high reusability and increased yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

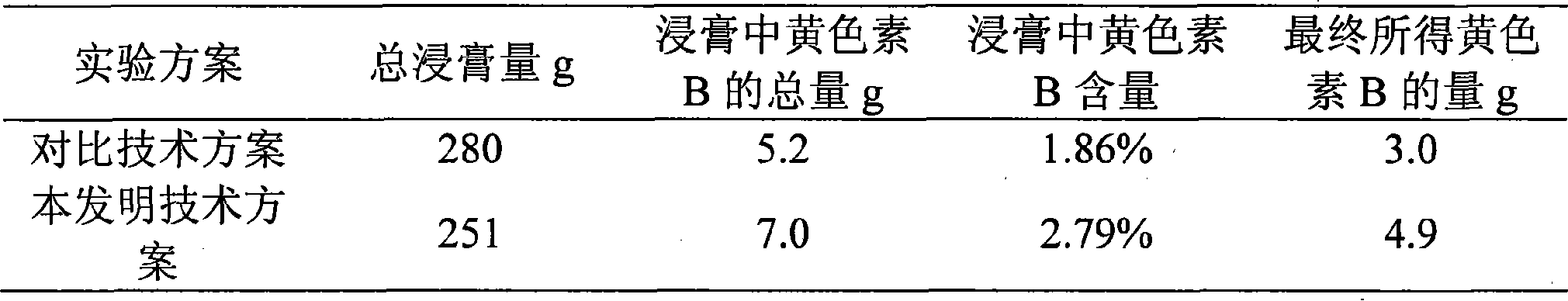

Examples

Embodiment 1

[0038]Weigh 20kg of dried safflower, soak it with 200L deionized water for 24 hours, then transfer it to the percolation barrel for percolation extraction, the flow rate is 0.06BV / min, and the medicinal materials are continuously replenished with fresh deionized water until the percolation liquid There is basically no safflower red pigment B in the medium, the total water consumption is 520L, the percolation liquid is combined, concentrated under reduced pressure at 60°C to a relative density of about 1.10, and put on the treated HP-20 macroporous adsorption resin column, the resin consumption is 20L, First elute 5 column volumes with 10% ethanol, discard this part of the eluate, and use 50% ethanol to elute, until the remaining liquid is basically free of safflower yellow B, combine the 50% ethanol eluate, Concentrate under reduced pressure at 60°C to a relative density of 1.20, add 95% ethanol under stirring to make the alcohol content 81%, leave it in a cold place for 24 hou...

Embodiment 2

[0040] Weigh 20 kg of dried safflower, soak it with 60% ethanol for 24 hours, then transfer it to the percolation bucket, and carry out percolation extraction. The flow rate is 0.06BV / min. There is basically no safflower red pigment B in the liquid, a total of 520L is used with 60% alcohol, the percolation liquid is combined, concentrated under reduced pressure at 60°C to a relative density of about 1.10, and put on a treated AB-8 macroporous adsorption resin column , the amount of resin used is 20L, first elute with 5% ethanol for 5 column volumes, discard this part of the eluate, and use 30% ethanol to elute, until the effluent is basically free of safflower yellow B, merge 30% Ethanol eluate, concentrated under reduced pressure at 60°C to a relative density of 1.20, added 95% ethanol under stirring to make the alcohol content 75%, left it in a cold place for 24 hours, a yellow precipitate precipitated, filtered, took the yellow precipitate, added 4 times The precipitated de...

Embodiment 3

[0042] Weigh 20kg of dried safflower, soak it with 200L of 50% ethanol for 24 hours, then transfer it to the percolation barrel, and carry out percolation extraction. The flow rate is 0.06BV / min. There is basically no safflower red pigment B in the filtrate, a total of 520L of 50% ethanol is used, the percolation liquid is combined, concentrated under reduced pressure at 60°C to a relative density of about 1.10, and the treated D-101 macroporous adsorption Resin column, the amount of resin used is 20L, first elute with 15% ethanol for 5 column volumes, discard this part of the eluate, and use 40% ethanol to elute until the remaining liquid is basically free of safflower yellow B, combine 40% ethanol eluate, concentrate under reduced pressure at 60°C to a relative density of 1.20, add 95% ethanol under stirring to make the alcohol content 85%, leave it in a cold place for 24 hours, a yellow precipitate precipitates, filter, and take the yellow precipitate, Add 5 times the amoun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com