Automatization materials conveying system

A technology for conveying systems and materials, applied in the direction of conveyors, conveyor objects, mechanical conveyors, etc., which can solve problems such as blockage of conveying vehicles 30, speed reduction, and affecting the delivery efficiency of process products, so as to reduce manufacturing costs and improve delivery efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

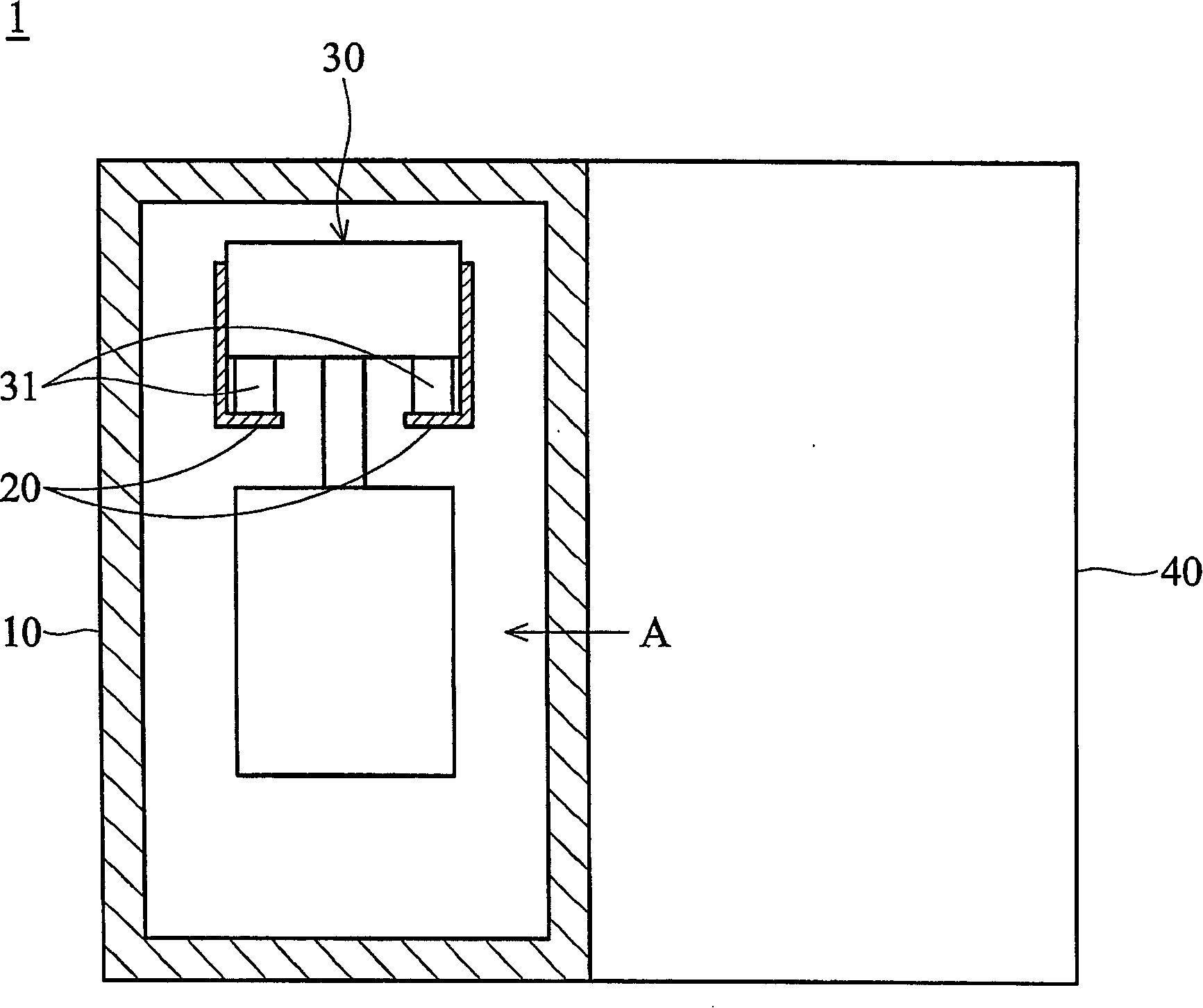

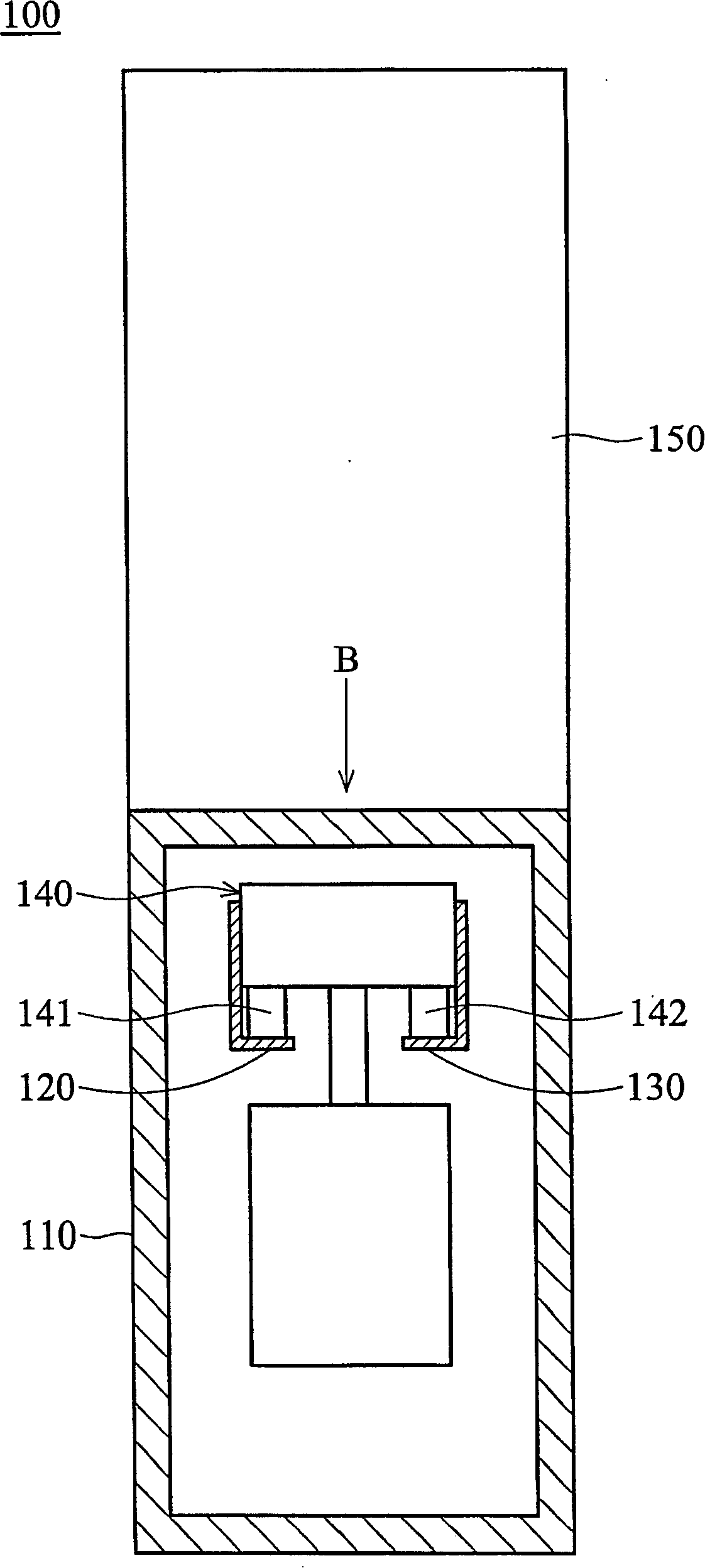

[0035] see Figure 2A and Figure 2B , the automated material conveying system 100 of this embodiment can be applied to conveying process products in a semiconductor factory, and mainly includes a fire prevention passage 110, a first track 120, a second track 130, and a plurality of transport vehicles 140 ( Figure 2A and Figure 2B only shows a transport vehicle 140) and a plurality of fire doors 150 ( Figure 2A Only one fire door 150 is shown in .

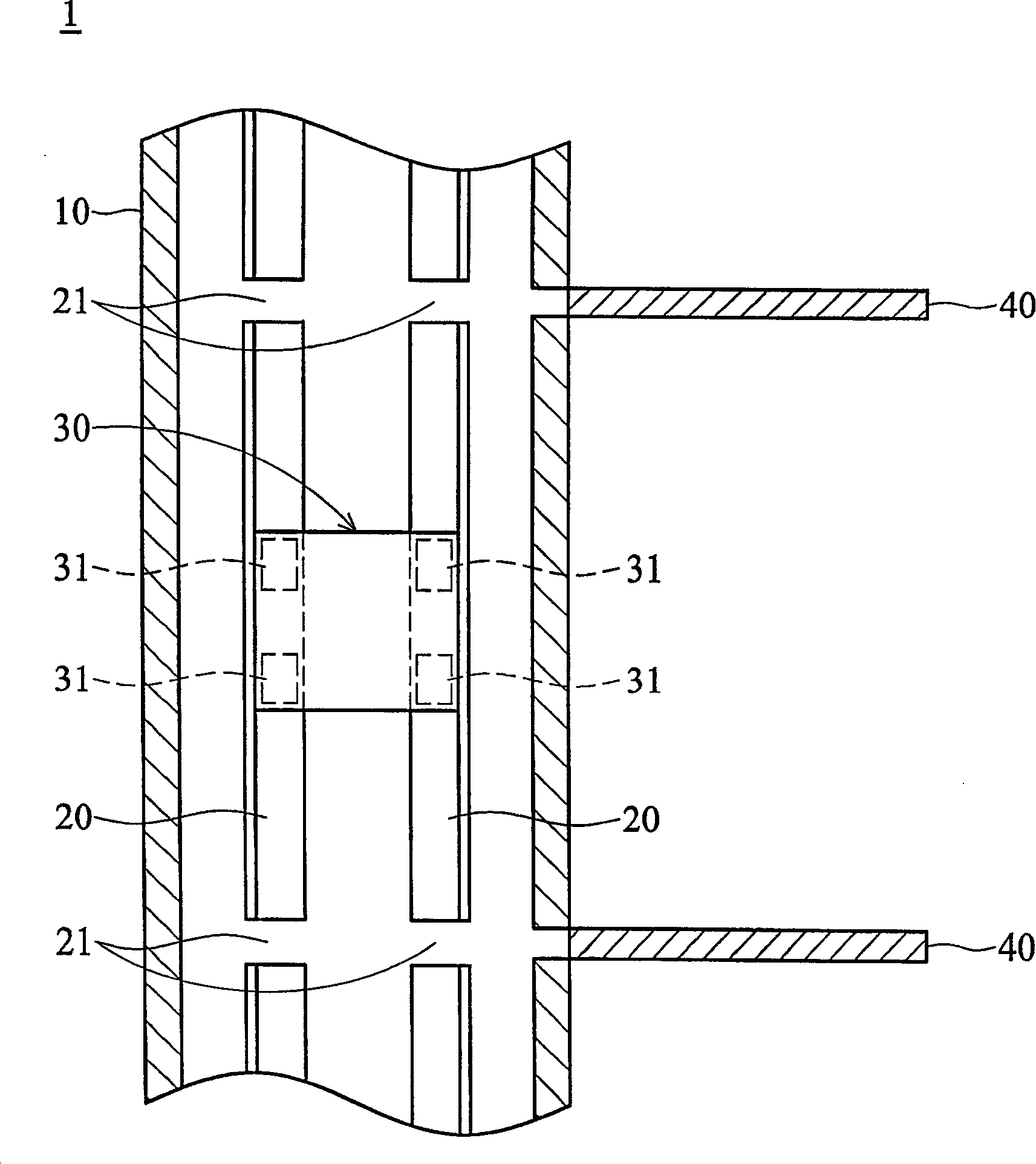

[0036] The first track 120 is disposed in the fire escape passage 110 , and the first track 120 has a plurality of first gaps 121 . The plurality of first gaps 121 are spaced apart from each other by a predetermined distance d.

[0037]The second track 130 is disposed in the fire escape 110 , and the second track 130 is parallel to the first track 120 . The second track 130 has a plurality of second gaps 131 . The plurality of second gaps 131 are also spaced apart from each other by a predetermined distance d. It should b...

no. 2 example

[0045] In this embodiment, the same elements as those in the first embodiment are marked with the same symbols.

[0046] see Figure 4A and Figure 5 The biggest difference between the automated material delivery system 100' of this embodiment and the automated material delivery system 100 of the first embodiment lies in the different shapes of the fire doors.

[0047] like Figure 5 As shown, the fire door 150' of this embodiment has a generally lightning-shaped shape. At the same time, if Figure 4B As shown, the relative position of each first gap 121 and each second gap 131 must also correspond to the shape of each fire door 150'.

[0048] Likewise, each first gap 121 is inclined to the axle 141a of the first wheel 141 at a predetermined angle θ, and each second gap 131 is also inclined to the axle 142a of the second wheel 142 at a predetermined angle θ.

[0049] As for other components or features of this embodiment are the same as those of the first embodiment, in o...

no. 3 example

[0054] In this embodiment, the same elements as those in the first or second embodiment are marked with the same symbols.

[0055] see Image 6 The biggest difference between the automated material delivery system 100" of this embodiment and the automated material delivery system 100' of the second embodiment lies in the structure of the fire doors.

[0056] like Image 6 As shown, the automated material delivery system 100" of this embodiment has a plurality of first fire doors 151 and a plurality of second fire doors 152 ( Image 6 Only one first fire door 151 and one second fire door 152 are shown). The first fire door 151 and the second fire door 152 also have a substantially lightning-shaped shape respectively, and the relative position of each first gap 121 and each second gap 131 must be the same as that of each first fire door 151. corresponding to the shape. In particular, if Figure 4B and Image 6 As shown, each first fire door 151 is connected to the fire esc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com