Radish and kohlrabi pickles filament cutter

A shredding machine and big head technology, applied in metal processing and other directions, can solve the problems of single filament and low labor efficiency, and achieve the effect of high speed and good shredding effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

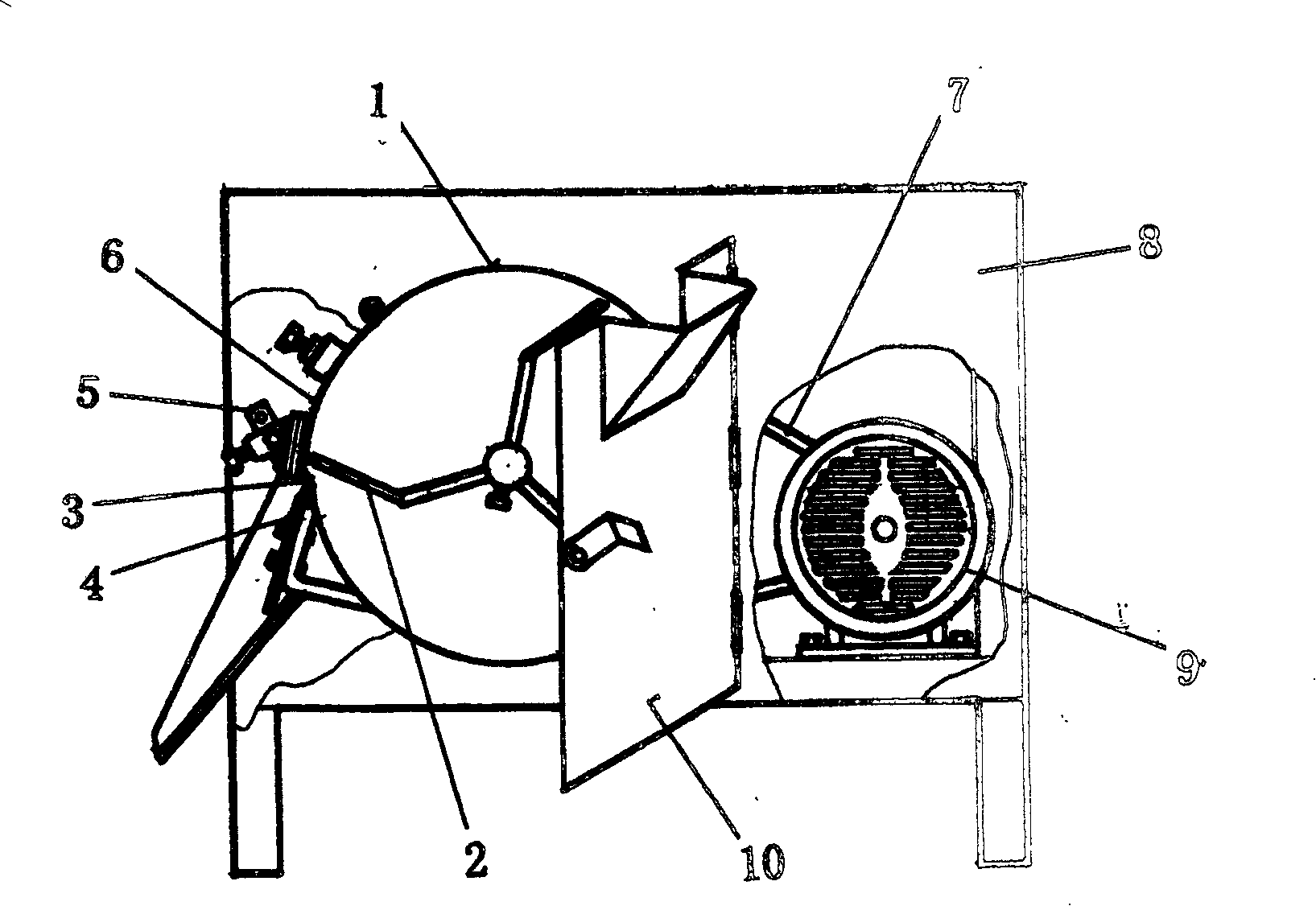

[0011] figure 1 Middle: several rotating plates 2 are installed on the rotating shaft in the middle of the material cylinder 1 in the frame 8, and a flat blade 4 and several vertical blades 5 are fixed at the lateral opening 3 on the outside of the material cylinder 1. The top of 3 can adjust the width adjustment baffle plate 6 of transverse opening 3 by hinge connection, and the inboard of its material cylinder 1 is provided with transmission device 7.

[0012] The transmission device 7 inside the material cylinder 1 is connected with the electric motor 9, and during use, it can also be connected with a gasoline engine or a diesel engine.

[0013] The outside of the material cylinder 1 in the frame 8 is provided with a switch door 10 that can close the material cylinder 1 .

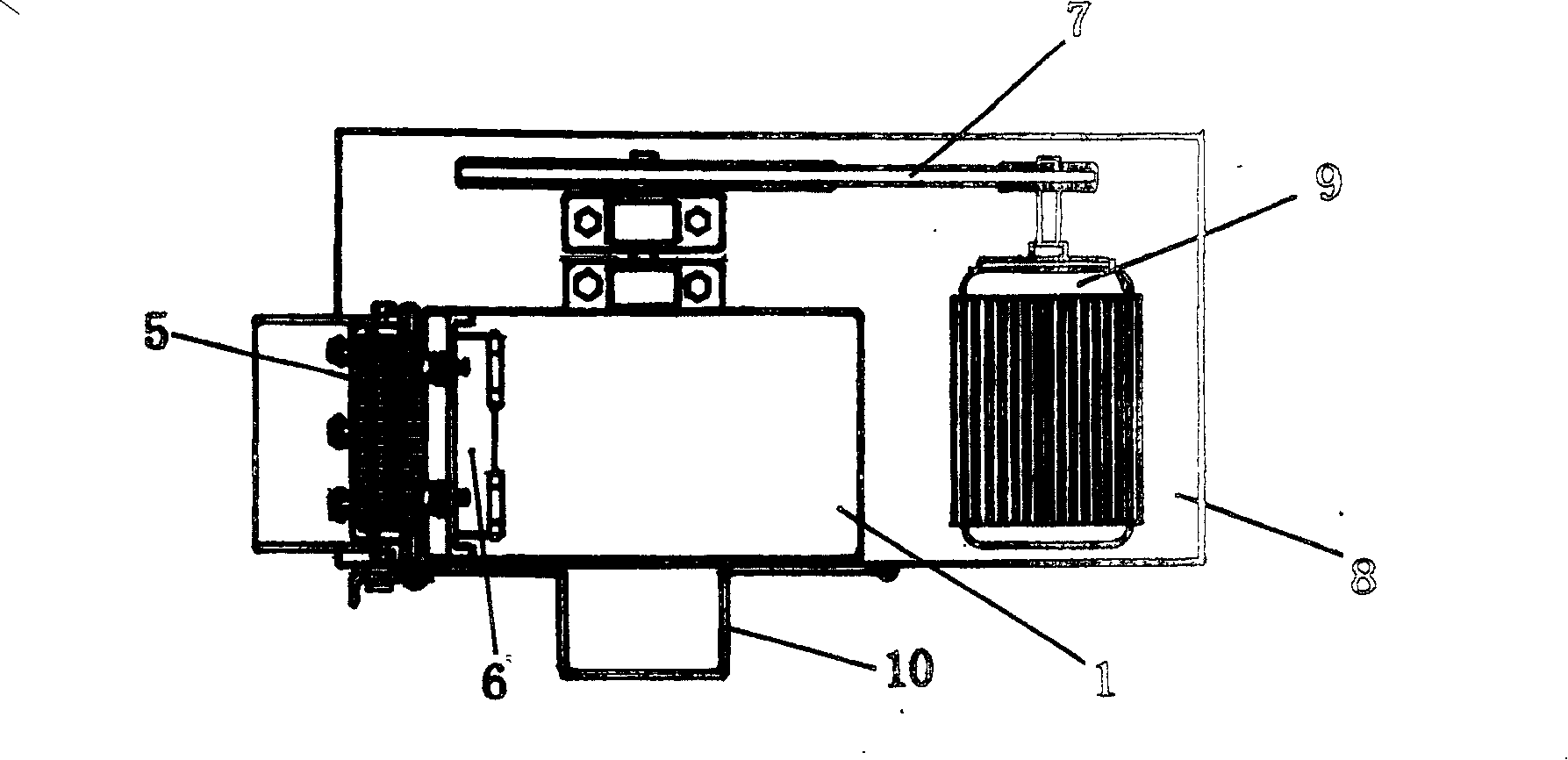

[0014] figure 2 Middle: The inner transmission device 7 of the material cylinder 1 in the frame 8 is connected with the motor 9, and the switch door 10 is arranged on the outer side, and several paral...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com